and repairs

During all maintenance / repair operations, the

components used must be warranted to maintain

all the machine’s hygiene and safety requirements.

Using the machine’s original spare parts constitute

an effective warranty.

After repair or component replacement operations

involving parts coming into contact with water and/or

food, it is necessary to run the machine washing

procedure as specied under the installation and

rst-time start-up section herein.

Have been tted with economizers which do not

draw water from the boiler to make hot water, the

water in the boiler need only to be renewed from

time to time.

(Fig.13)

Must be performed by a certied factory trained

technician only.

● Turn off the machine and wait for the pressure in

the boiler to diminish (gauge needl on “0”).

● Dismantle the reservoir by working on the screws

(Fig. 10)

● Insert a rubber hose into the hose-end tting (3)

(Fig.13)

● Use the wrench (1) to immobilize the tting (2) and

loosen the hose-end tting (3).

● Allow the water to ow out completely; then, close

the tting (3) and remove the rubber hose.

● Rell the boiler (paragraph 7.3.).

Whenever descaling operations are ne-

cessary, ensure that only specic products

suitable for parts contacting water for public,

human consumption are used. Make sure

that all the relative product instructions are

carefully observed and complied with at all

times.

Fig.12)

Operation to be carried out when the machine is off

and cold.

● Prepare a solution of 4 packages of detergent

powder Code dissolved in a litre of

boiling water in a stainless steel, plastic or glass

recipient ().

● Remove the lters and immerse them with the lter

holders in the prepared solution, leaving them for

at least 10/20 minutes (all night is better).

● Remove them from the container and rinse them

thoroughly in running water.

● Remove the cup-holder grid 1 (Fig. 11) and clean

discharge 2 (Fig. 11)

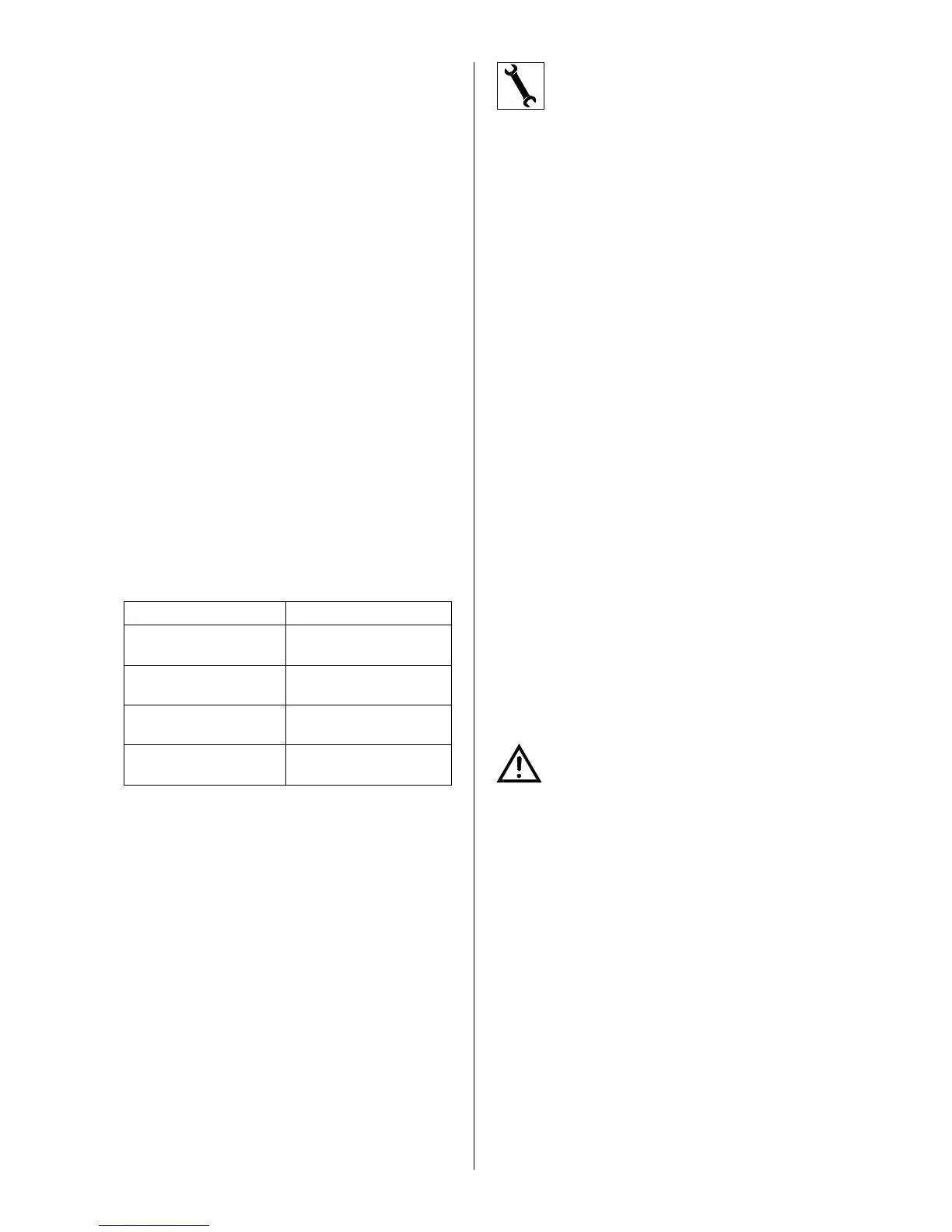

Stage

Wa i t – R e ad y fo r

washing

SLOW ashing orange

+ blue

Washing in progress Orange + 1 FLASHING

blue

Wait – Ready for rin-

sing

FAST flashing orange

+ blue

Rinsing in progress Orange + 2 FLASHING

blue

● Insert the blunt lter membrane inside the lter-

holder and then add a spoonful of coffee machine

detergent powder and then assemble the lter-

holder onto the unit to be cleaned.

● Activate the washing phase by pressing the coffee

dispensing button. The machine will undertake

10 washing cycles lasting 10s each with a 10s

interval the led will be orange colour with a short

blue ashing interval in between.

● At the end of the washing operation the machine

goes into l stand-by and the led will begin to ash

rapidly alternating orange and blue. Dismantle

the lter-holder remove the lter membrane and

then re-assemble the whole thing.

● Enable the rinse function by pressing the coffee

dispensing button. The machine will undertake 3

rinse cycles lasting 30s each followed by a 10s

pause, the led will be orange with a short blue

ashing interval.

● At the end of the cycle the led switches off and

the machine is ready for a new coffee dispensing

operation.

Note: it will be possible to interrupt both the washing

and the rinsing stages by pressing the coffee

dispensing button twice, in the rst case the

machine will go on to the stand-by stage ready

for rinsing, while in the second case it returns to

the normal ready-for-use mode.

Loading...

Loading...