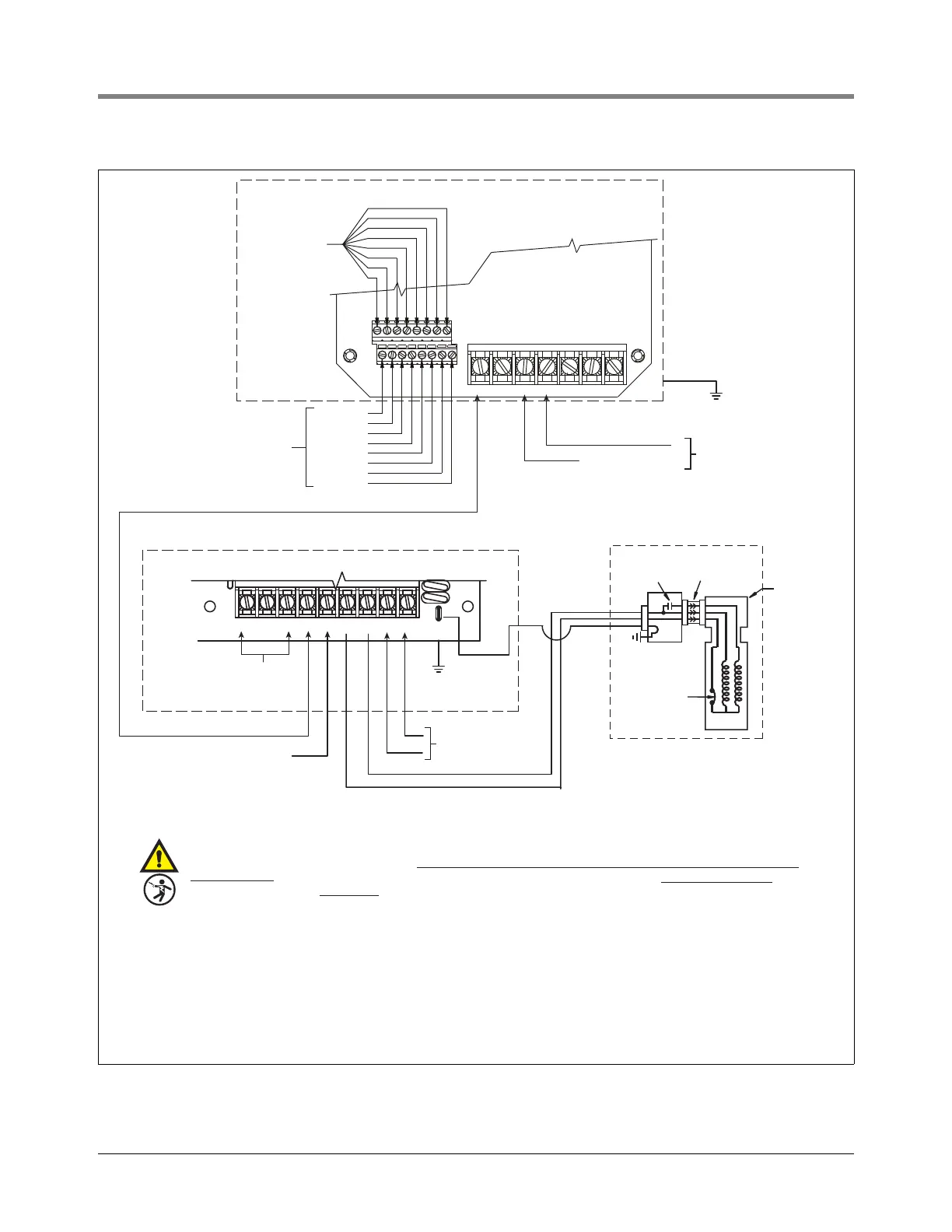

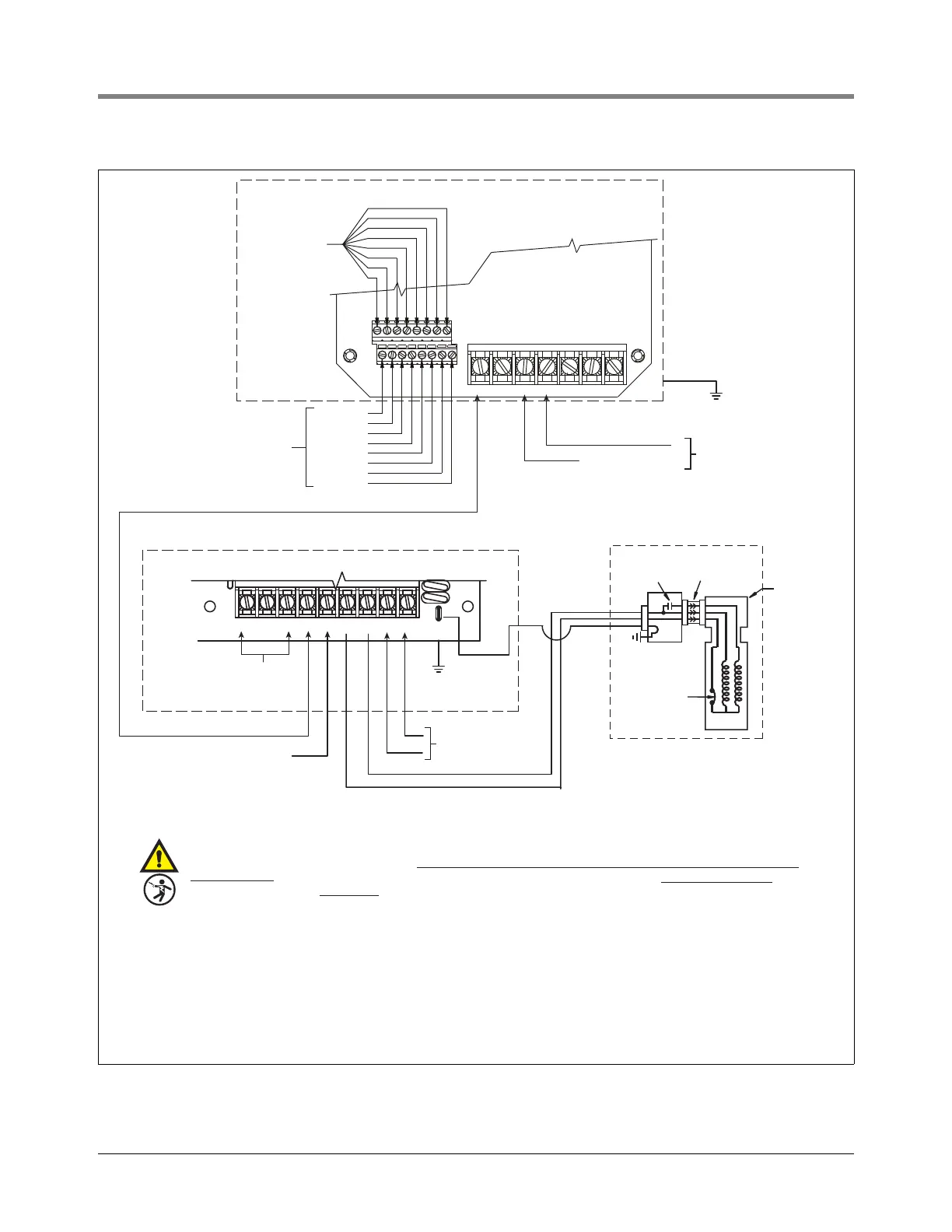

Figure 19. Isotrol to IQ System Wiring - 120 Volt Dispenser Signals

COM+

C23

TB1

D2COM- SHLD D1 M2 L1M1 L2

GND

Z2

Z3

IQ CONTROL BOX (P/N 880-051-1)

ISOTROL CONTROL BOX (P/N 880-049-1)

NEUTRAL

(FROM SUPPLY PANEL)

208/230 VOLT

FROM SUPPLY

PANEL

CHANNEL 1

CHANNEL 2

CHANNEL 3

CHANNEL 4

CHANNEL 5

CHANNEL 6

CHANNEL 7

CHANNEL 8

120 VOLT

DISPENSER

SIGNALS

UNSWITCHED

NEUTRAL TO TB2

TB1

L1

UNSWITCHED NEUTRAL

NOT

USED

NOT

USED

NOT

USED

NOT

USED

1

2

3 456 78

DISPENSER INPUTS

PHASE ON L1 MUST BE SAME AS DEVICE

CONNECTED TO ATG TERMINAL

HOT

NEUTRAL

TB2

AT G

NL1L2M2M1S

RS-485 CONNECTIONS

INSTALL IN CONDUIT

(MANIFOLDED UNITS

ONLY)

CONNECT TO

ELECTRICAL

GROUND

CONNECT TO

ELECTRICAL GROUND

120 V FROM

SUPPLY PANEL

120 VOLT ISOLATED OUTPUT TO IQ CONTROL BOX

153-8.eps

ISOTROL CONTROL BOX WIRING PRECAUTIONS

WARNING! This device is intended to provide electrical isolation between the dispenser pump enable (Hook) signal and the

submersible turbine pump (STP) control relay. Other energized sources of power can still exist within the dispenser even

with this device. The neutral connection to the N terminal of TB1 and N terminal of TB2 must be from the service panel and be

a permanently connected, unswitched connection.

The N connection on TB1 and the eight N connections on TB2 may b

e spliced to a common neutral wire from the service panel

described above.

Make only one "wire" connection on each N terminal on TB2.

CAUTION! The phase of L1 (TB1) must match the phase of the power supplying the ATG device in order to prevent cross phasing

which may damage the input on some ATG equipment.

GENERAL WIRING PRECAUTIONS

Wiring must be rated 90°C minimum.

Make ground connection in accordance with local codes.

Electrical

interlock

Internal

overload

protector

Continuous

duty capacitor

Extractable

packer

Junction box

in manifold

Motor

STP

R

B

O

G

Loading...

Loading...