27

Auxiliary Equipment Operation

GENERATOR-TYPICAL

Perform the following inspections and checks before each

startup, as designated, and at regular intervals as noted in

the service schedule.

1. Air Inlets- Check for clean and unclogged air inlets.

2. Air Shrouding- Ensure the sound shield enclosure is

securely fastened and positioned correctly.

3. Battery- Check for proper electrolyte level. Make sure

all battery connections are secure.

4. Coolant Level- Check the reservoir for proper levels.

5. Exhaust System- Check for exhaust leaks and block-

ages. Check the silencer and piping condition and check

for tight exhaust component connections.

Inspect the exhaust parts (exhaust manifold, catalyst, ex-

haust hose, hose clamps, silencer and outlet fl apper) for

cracks, leaks and corrosion.

Check hoses for cracks, softness, dents, or leaks. Replace

as necessary.

Check for corroded or broken metal parts. Replace as

necessary.

Check for loose, missing or corroded hose clamps. Re-

place or tighten the hose clamps and hangers as needed.

Check that the exhaust outlet is unobstructed.

Visually inspect for exhaust leaks (blow-by). Check for

carbon or soot residue on exhaust parts which indicate an

exhaust leak. Seal leaks as needed.

As optional equipment a gasoline or diesel generator is

available on your boat depending on engine option cho-

sen.

Current generators are more powerful yet more compact

in size. They run at a slower rpm for longer life.Today

domestic gas generators are rated at 5 kw (120-240 volts,

60 hertz) and diesel units rated at 6 kw (240 volts, 50

hertz). Both meet current EPA, CARB and CE emission

requirements.

Detailed maintenance information can be found in the generator

operating manual.

For general generator information see chapter 4 of this man-

ual.

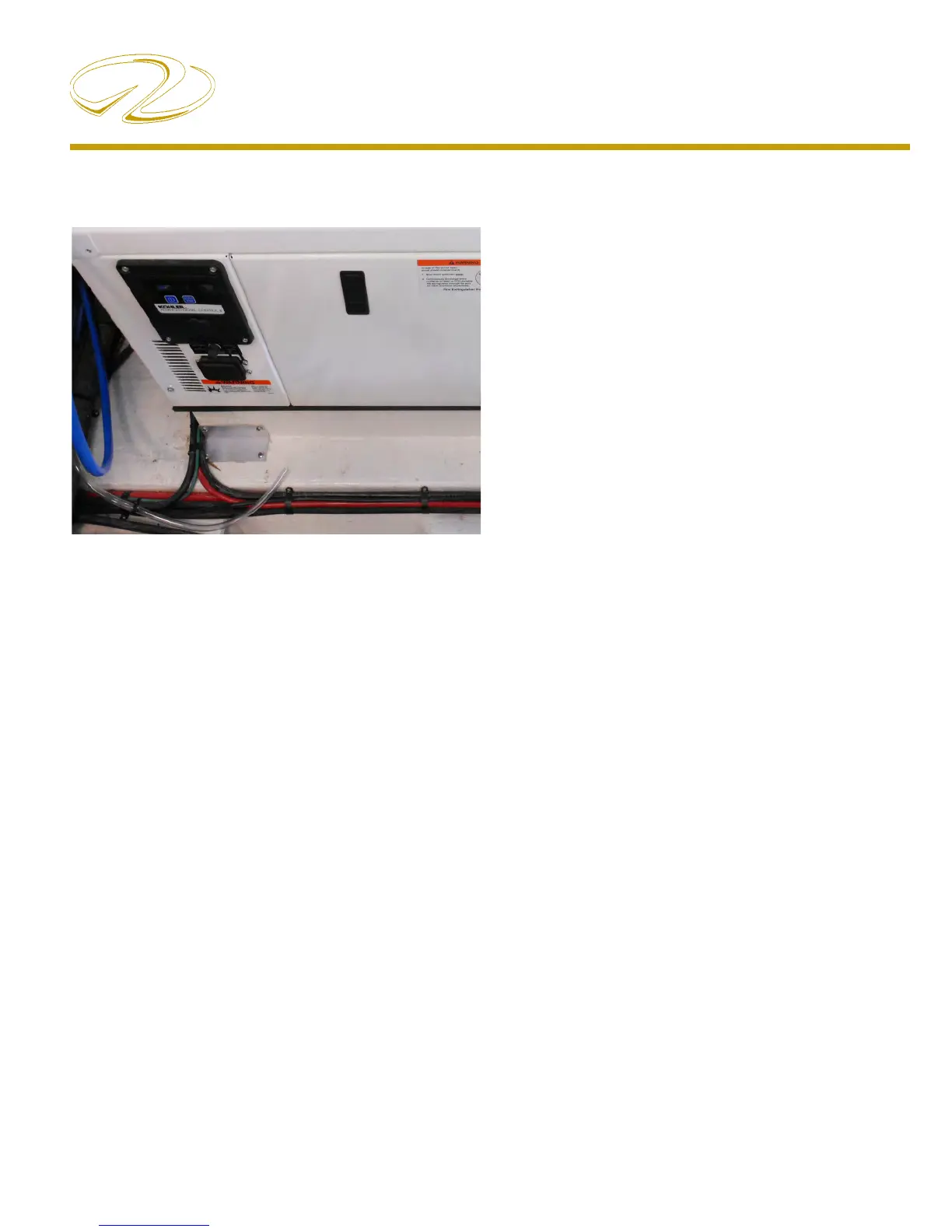

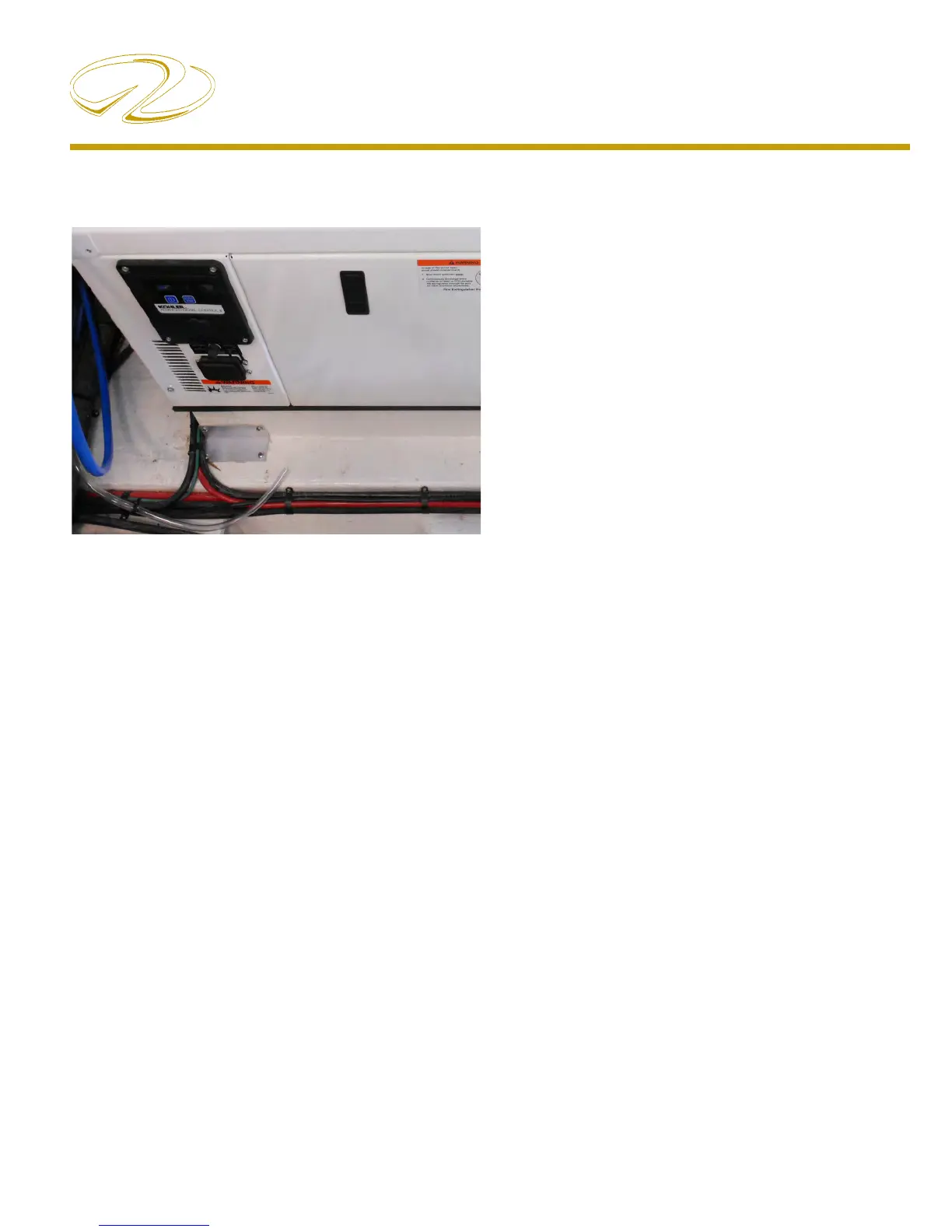

OVERVIEW

OPERATION

Sound Shield

Shown

Loading...

Loading...