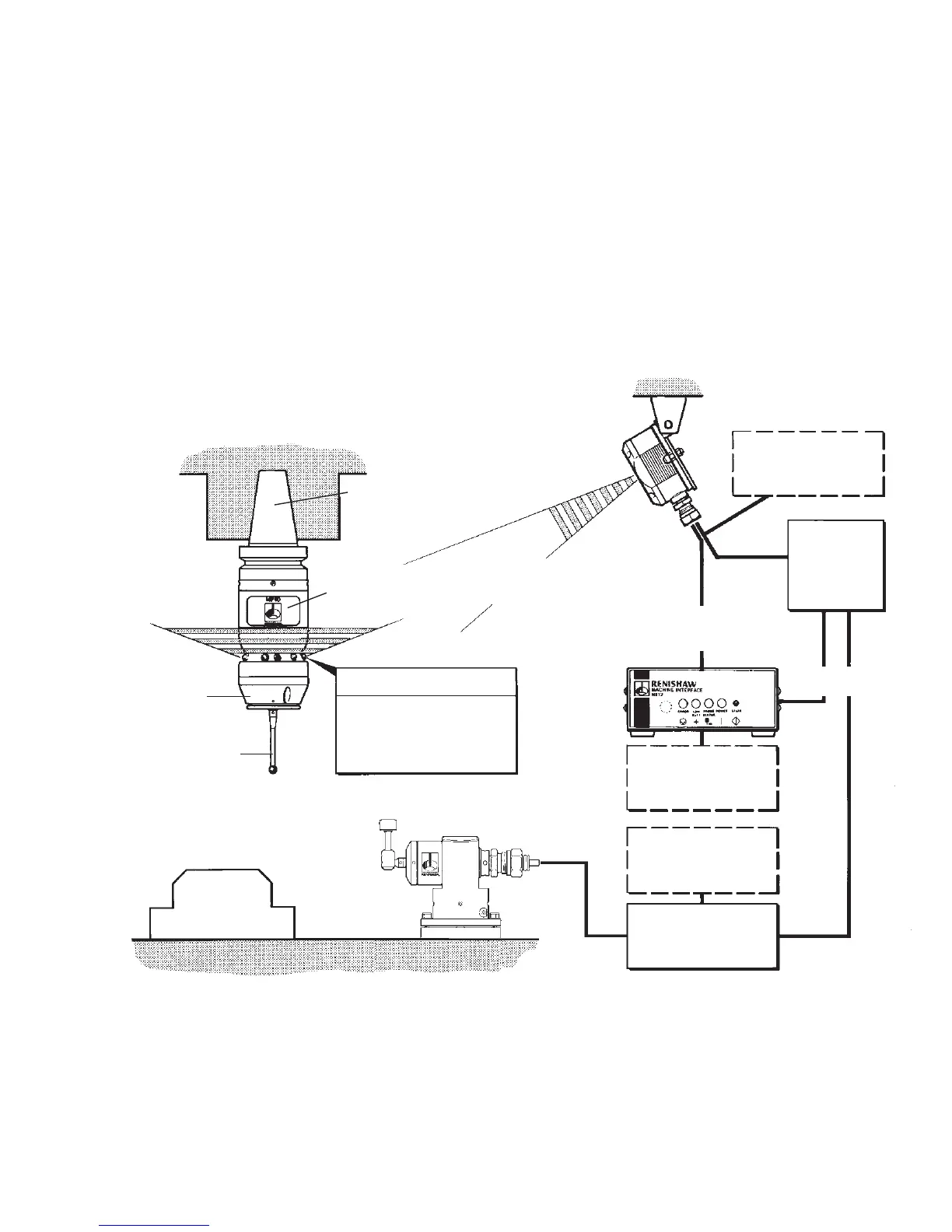

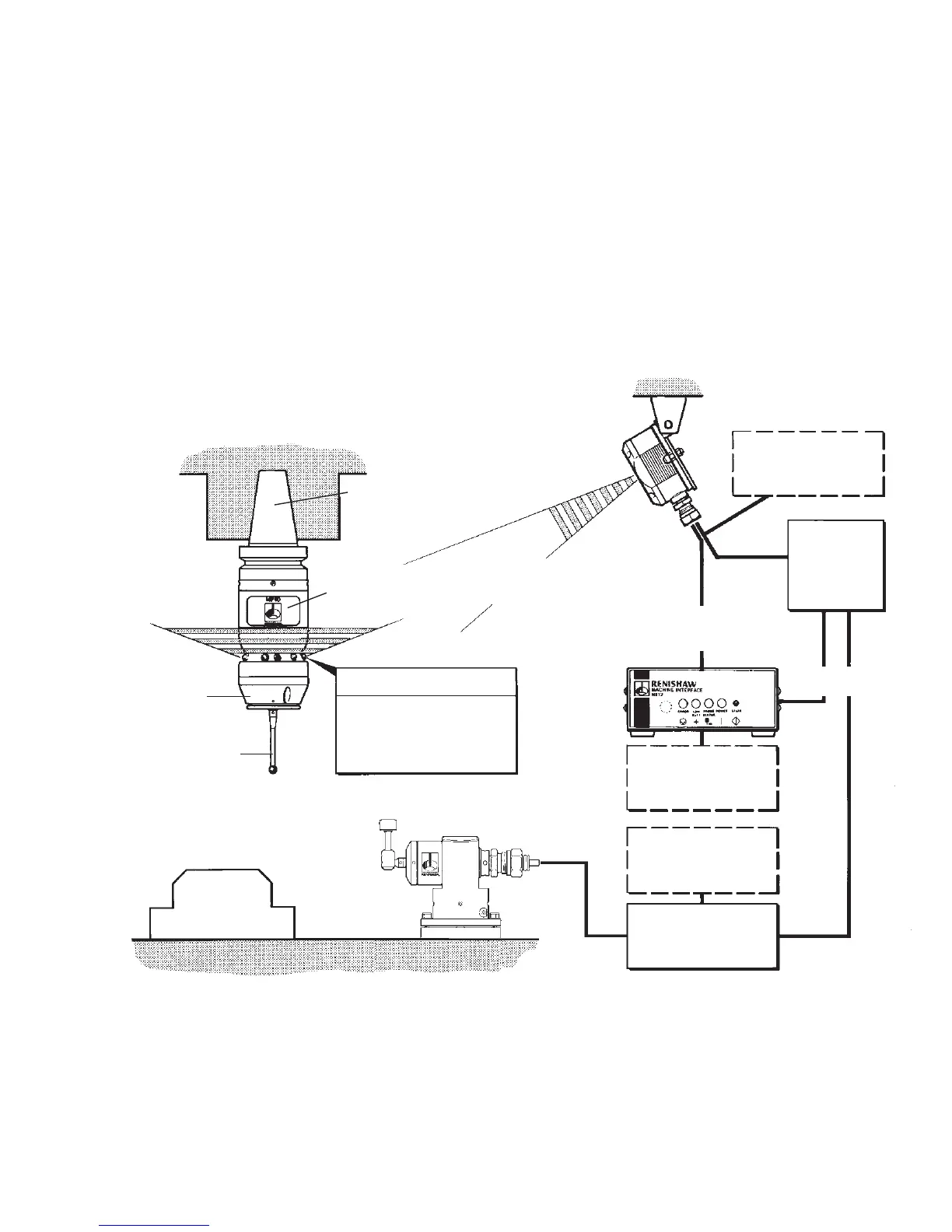

A workpiece set-up and inspection probe is in effect another

tool in the system. A probe cycle may be included at any

stage of the machining process.

Signals are transmitted between the probe and the machine

control, via the OMP and OMM + MI 12 or alternatively the

OMP and OMI.

TYPICAL PROBE SYSTEMS

1-2

Workpiece

Probe head

Stylus

Machine spindle

Typical tool

setting probe

CNC

machine

control

Cable

Battery cover

Shank (size 25 - 50)

Optional - PSU3

power supply unit

Optional - PSU3

power supply unit

OMP - LEDs

Mounting bracket

OMI (one only)

+ CNC control

Optional - PSU3

power supply unit

MP10

inspection

probe

3 x Receive diodes

6 x Transmit LEDs

1 x Probe status LED

MI 12 interface unit

or MI 12 board

OMM (one or two)

+ MI 12

+ CNC control

MI 5, MI 8 or

MI 8-4

interface

unit

SEE PAGES 1-38, 1-39 & 1-40

OMM - Optical module machine

OMP - Optical module probe

OMI - Optical machine interface

Loading...

Loading...