15

Stylus alignment with the spindle’s centre line

need only be approximate, except in the following

circumstances.

1. When probe vector software is used.

2. When the machine control software cannot

compensate for an offset stylus.

How to check stylus position

Stylus tip and stem position are established using a

low force (less than 20 g [0.71 oz]) dial test indicator

or setting gauge. Alternatively, rotate the stylus ball

against a flat surface. Alignment is good when the

stylus ball maintains a consistent distance from the flat

surface.

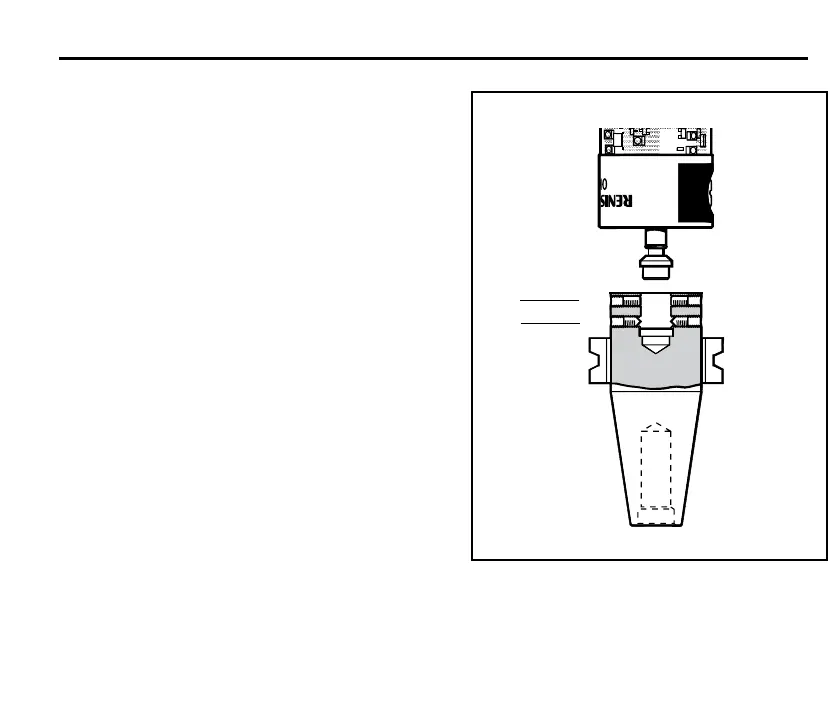

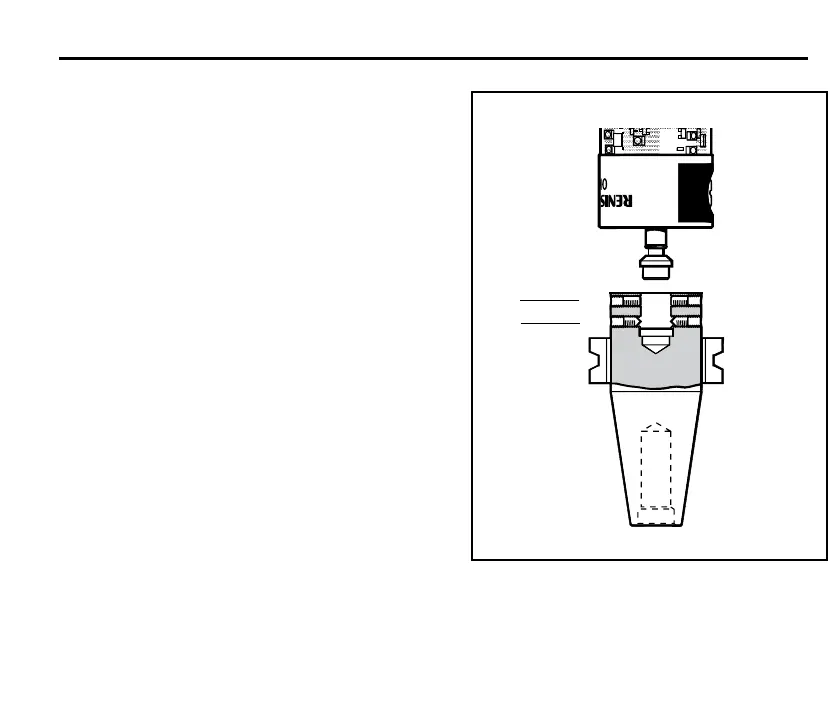

Stage 1 - Probe/shank mounting

1. Fully slacken screws

A. Then grease screws B,

and fit to shank.

2. Fit the probe onto the shank, and visually position

the probe centrally relative to the shank. Partially

tighten screws

B to 1 Nm (0.23 lbf).

3. Fit the probe/shank assembly into the machine

spindle.

PROBE

SHANK

A

➤

B

➤

Probe/shank mounting

Probe/shank mounting

Loading...

Loading...