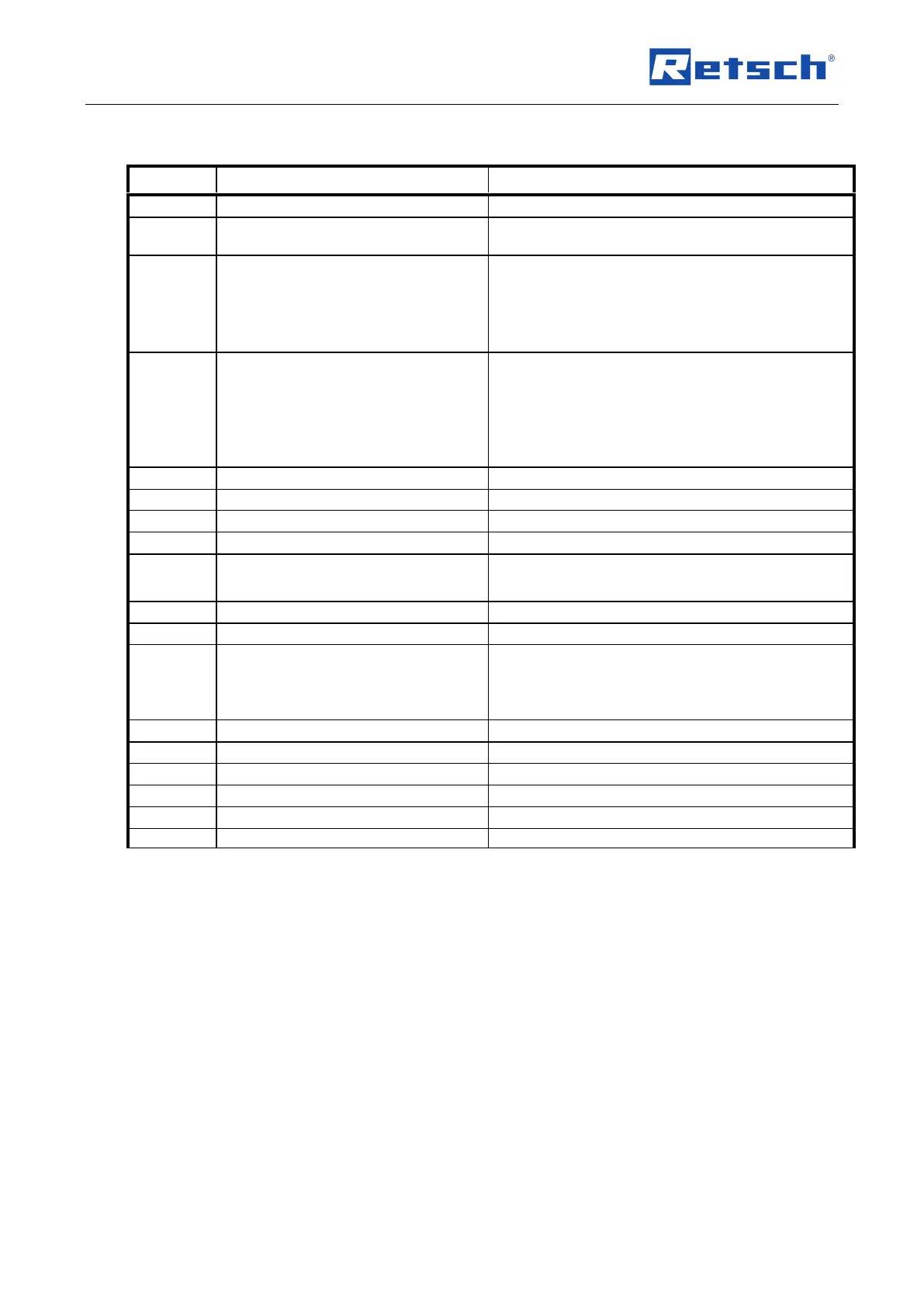

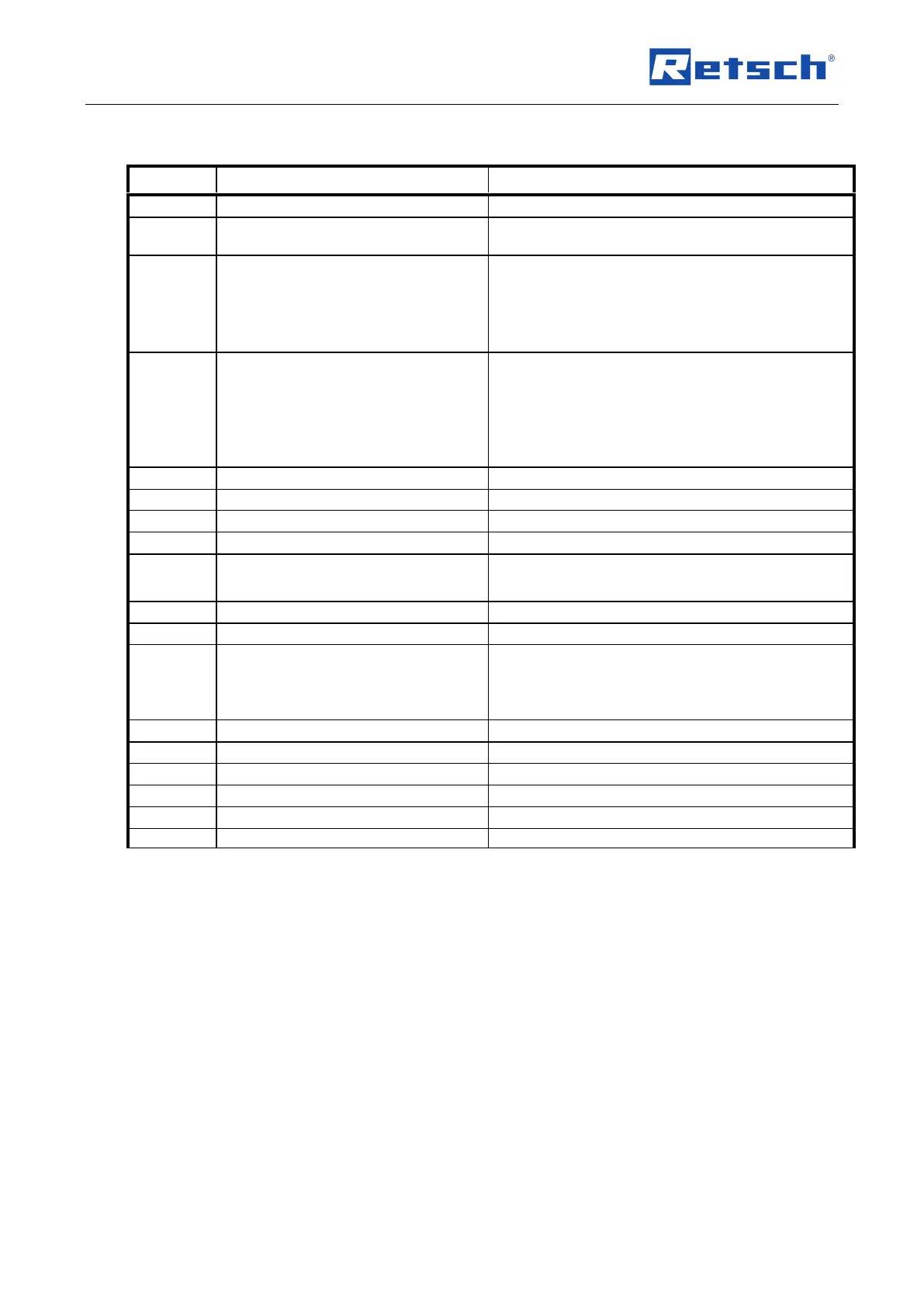

5.2 Overview table of the parts of the device

Feed hopper access barrier

Prevents people reaching into the feed hopper

When pulled, it releases the material feed chute.

Pushes sample onto the rotor.

Pushes the material to be ground into the feed hopper

area of the filling plunger

– Pulled out: the material can be fed.

– Pushed in: the material remains in the area of

the filling plunger.

Prevents the filling plunger being pulled out, blocks it or

releases it.

– Pulled out: allows the filling plunger to move

freely

– Released: filling plunger latches in the top

position

Allows the door to be opened

Starting and stopping the device, setting the speed

The size and type of its perforation influences the

fineness of the material being comminuted

Air outlet and sieve for sample material

Collects comminuted stock

ON/OFF switch (main switch)

Connecting and disconnecting the device to/from the

power grid.

- ON = LED (red) STOP lights up

- OFF = all LEDs are off

Accommodates the size reduction tool

Counterpart for the size reduction tool

For feeding the sample material

Fastening screws for feed hopper

Locking screws for the feed hopper

Closes the grinding chamber

Loading...

Loading...