Add: 5F

, No.4 building, No 4. Yard, life Rd, life science park,

Tel:010-53275118 Fax

returning home, and the sc

Manual control state initial interface

5.3.1

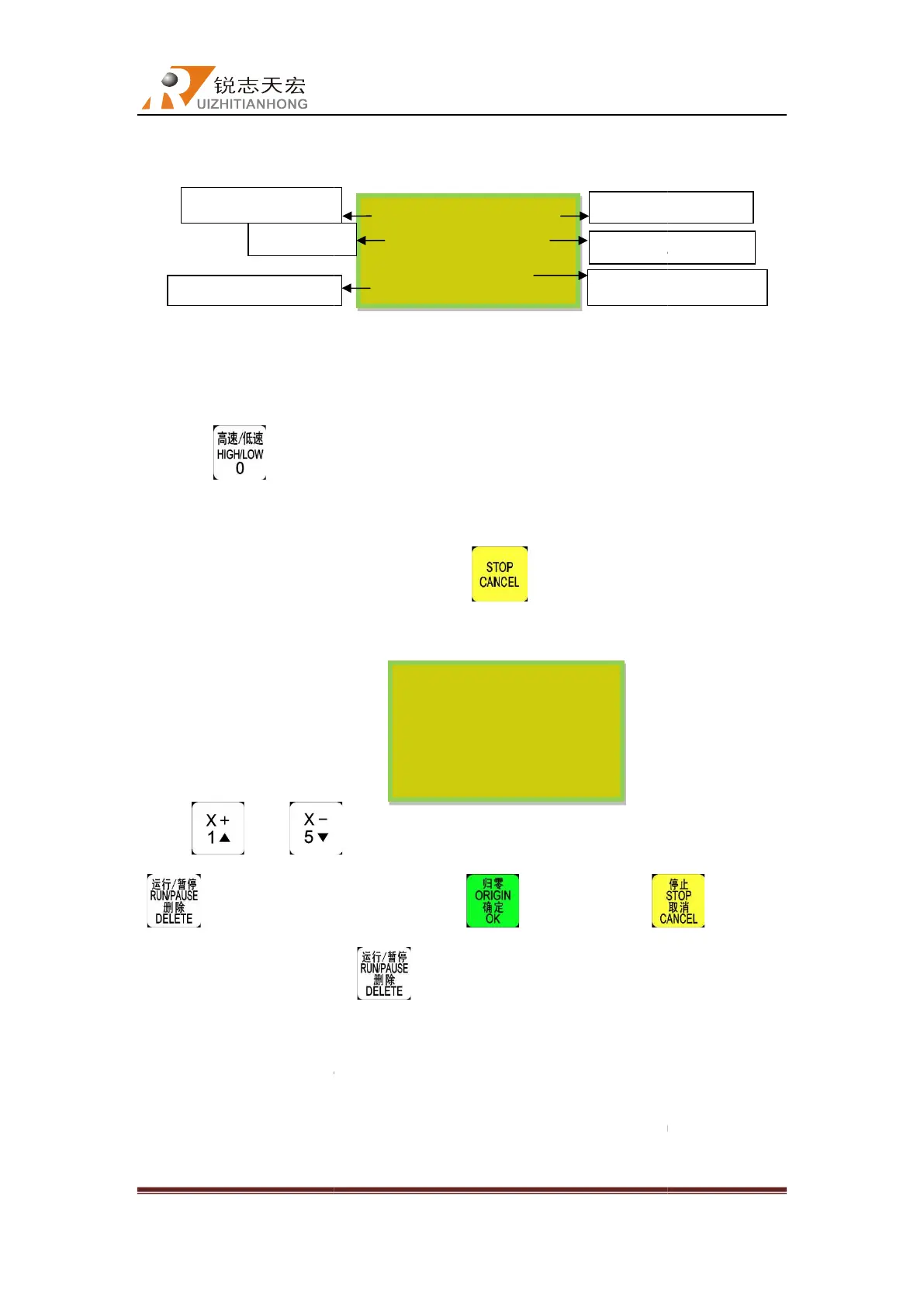

Manual operation speed switching and adjusting

There are two speed modes: high speed

pressing “

”. The speed mode you choose will decide the

speed.

2) Speed adjusting:

Under the manual operation mode, pressing “

the current speed mode is “L”, the dsp controller displays as follow:

Press“ ”or “

“

”button to modify the value, press “

input a wrong number, press “

In order to ensure the accuracy of processing and debugging, the system introduces

concept of grid which also called minimum feed. It range is 0.05mm

change mode into “step”,

the grid distance

About the high speed manual mode setting method is exactly the same as introduced

above.

Coordinate

Beijing RichAuto S&T Co., Ltd

, No.4 building, No 4. Yard, life Rd, life science park,

Beiqing St., Changping d

010-53275110/53275111 Web site:

:

Manual control state initial interface

:

Manual operation speed switching and adjusting

There are two speed modes: high speed

(F) and low speed(L)

. Change the speed mode by

”. The speed mode you choose will decide the

manual

Under the manual operation mode, pressing “

” to adjust current speed settings. If

the current speed mode is “L”, the dsp controller displays as follow:

”to move the cursor, then select the option and press

”button to modify the value, press “

” to save, press “

input a wrong number, press “

” to delete the last numbers and re-

In order to ensure the accuracy of processing and debugging, the system introduces

concept of grid which also called minimum feed. It range is 0.05mm

-

-axis direstion buttons, the mach

.

About the high speed manual mode setting method is exactly the same as introduced

WX

WY

WZ 0.000 L

Manual Param

XSLOW

YSLOW 1200.000

ZSLOW 1200.000

Slow Grid 0.100

Beijing RichAuto S&T Co., Ltd

Beijing, China

36

. Change the speed mode by

” to adjust current speed settings. If

”to move the cursor, then select the option and press

” to quit. If

In order to ensure the accuracy of processing and debugging, the system introduces

a

be moving at

About the high speed manual mode setting method is exactly the same as introduced

Loading...

Loading...