Add: 5F

, No.4 building, No 4. Yard, life Rd, life science park,

Tel:010-53275118 Fax

The start position of X, Y and Z in the processing program is the workpiece origin. Before

operation, we should pay

attention to this position as well as the real position. Operation is

as follow:

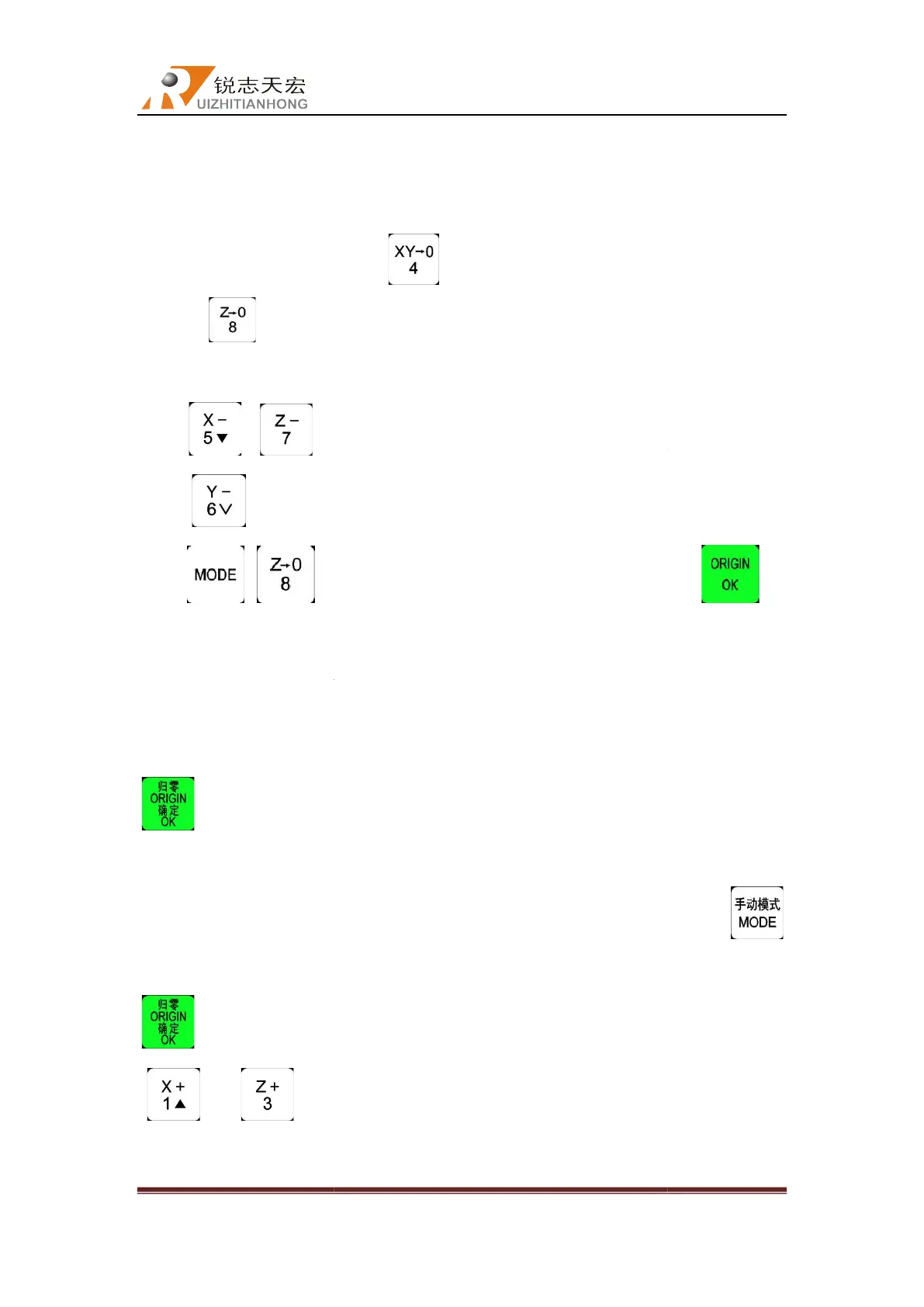

Manual move X,Y and Z to the position which will start to process the file on workpiece.

Afterwards, press zero clearing “

clearing “

” to decide the origin of Z axis.

Press“ ”/“

press “ ”

to move Y axis to a proper position too

keys “ +

save the setting.

5.4.3

Adjust the origin of the workpiece

If the user needs to reset workpiece origin, for example: needs to move Y direction or

adjust the cutters depth of X and Z axis. In this case, the user can

, the lath

axis will move to the settled origin

over the settled workpiece original point at the sa

button to change the manual mode into DISTANCE, input the value 10, and then press

button to save the distance as 10mm. At that time,

“ ”and“ ”,

Beijing RichAuto S&T Co., Ltd

, No.4 building, No 4. Yard, life Rd, life science park,

Beiqing St., Changping d

010-53275110/53275111 Web site:

The start position of X, Y and Z in the processing program is the workpiece origin. Before

attention to this position as well as the real position. Operation is

Manual move X,Y and Z to the position which will start to process the file on workpiece.

Afterwards, press zero clearing “

” to decide the origin of X,Y axis. Press zero

” to decide the origin of Z axis.

two cutters to reasonable and safety position,

to move Y axis to a proper position too

,

and then press the combination

location as stop position,

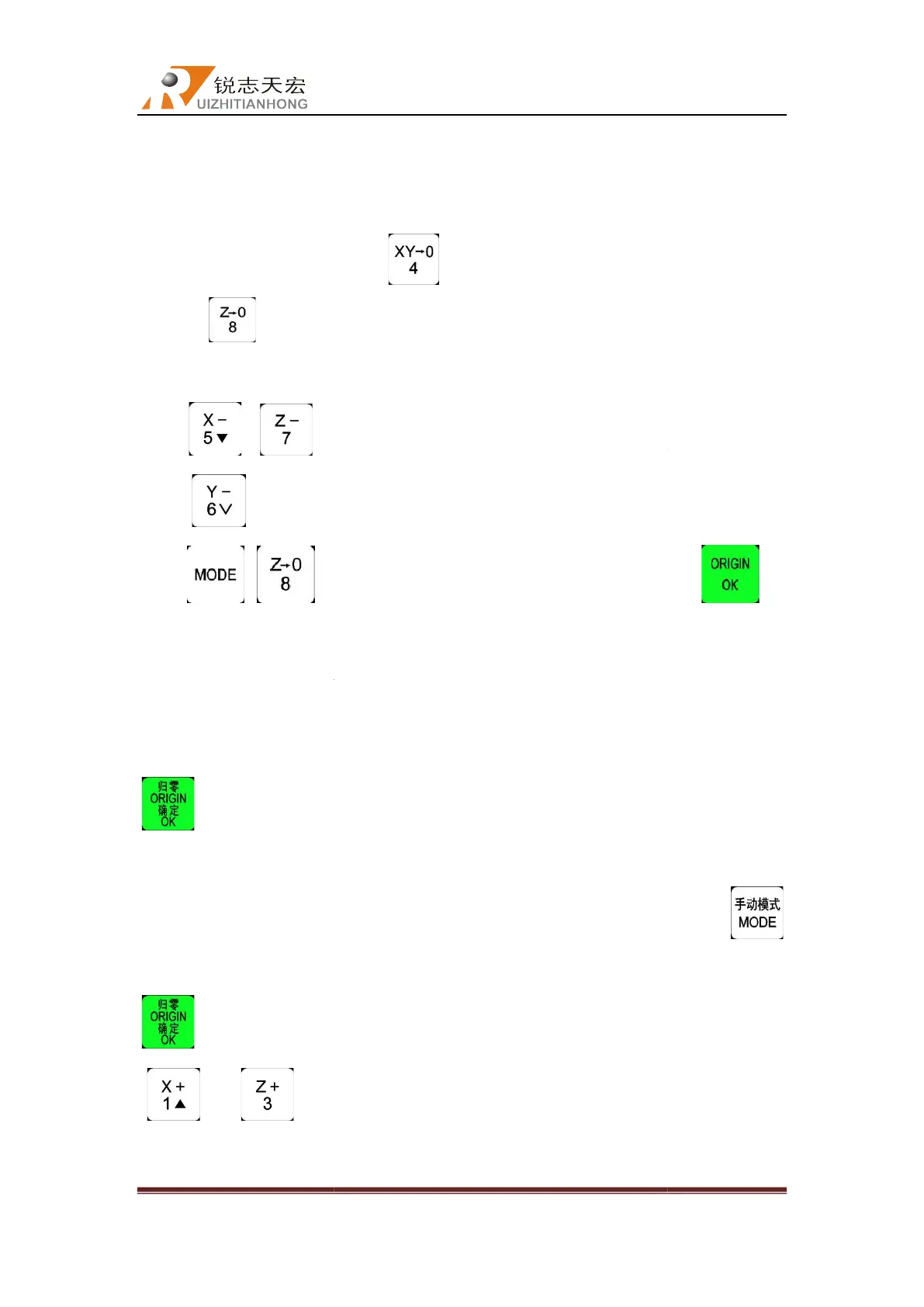

Adjust the origin of the workpiece

If the user needs to reset workpiece origin, for example: needs to move Y direction or

adjust the cutters depth of X and Z axis. In this case, the user can

will complete the moving of returning to workpiece origin, Y

axis will move to the settled origin

al position, and

cutters of X and Y axis will stop 10mm

over the settled workpiece original point at the sa

me time. Next, double

button to change the manual mode into DISTANCE, input the value 10, and then press

button to save the distance as 10mm. At that time,

the X and Y cutters moving

back to the settled position of

Beijing RichAuto S&T Co., Ltd

Beijing, China

39

The start position of X, Y and Z in the processing program is the workpiece origin. Before

attention to this position as well as the real position. Operation is

Manual move X,Y and Z to the position which will start to process the file on workpiece.

” to decide the origin of X,Y axis. Press zero

two cutters to reasonable and safety position,

then

and then press the combination

” to

If the user needs to reset workpiece origin, for example: needs to move Y direction or

will complete the moving of returning to workpiece origin, Y

cutters of X and Y axis will stop 10mm

the

button to change the manual mode into DISTANCE, input the value 10, and then press

button to save the distance as 10mm. At that time,

single press

back to the settled position of

Loading...

Loading...