3004

8

GB

4. WORKING

4.1 COMBUSTION ADJUSTMENT

In conformity with EN267, the installation of the burner to the heat generator, setting and testing must all be

performed in respect of the instruction manual for the heater, including the controls on the concentration of

CO and CO

2

in the flue gases, the flue gas temperature and the average water and air temperatures in the

generator.

To suit the required appliance output, choose the proper

nozzle and adjust the pump pressure, the setting

of the combustion head, and the air damper opening in accordance with the following schedule.

The values given in the table refer to a CEN boiler (in accordance with EN 267). They refer to 12.5% of

CO

2

, at sea level, room temperature and light oil temperature at 20°C, 50 Hz power frequency and com-

bustion chamber counterpressure at 0.

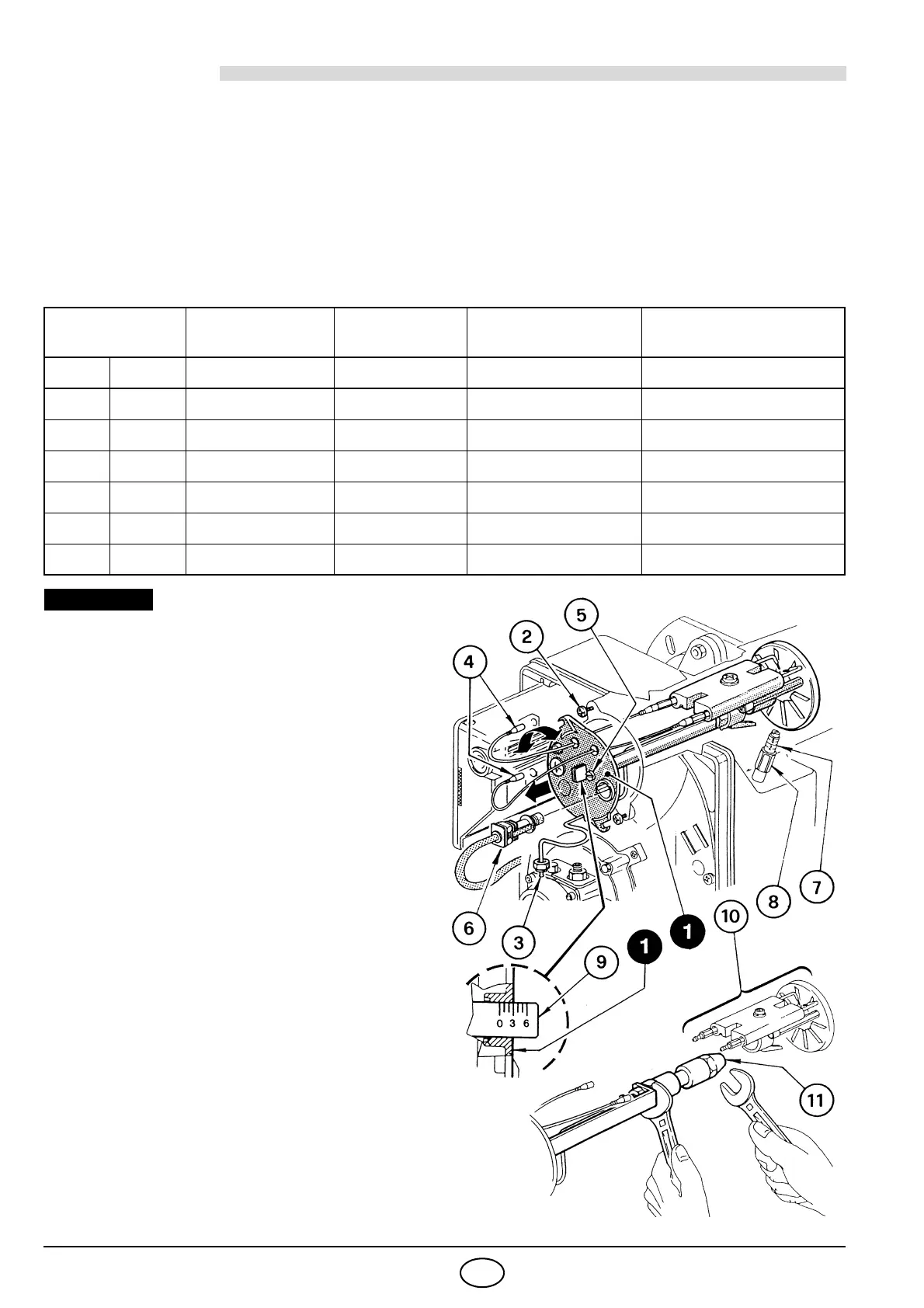

Nozzle

Pump

pressure

Burner

output

Combustion head

adjustment

Air damper

adju

stment

GPH Angle bar kg/h ± 4% Set-point Set-point

2.50 60° 12 10.0 0 1.4

3.00 60° 12 12.0 1 2.1

3.50 60° 12 14.0 2.5 3.0

4.00 60° 12 16.1 4 3.5

4.50 60° 12 18.1 6 4.5

4.50 60° 14 19.5 6 6.0

The values given in the table are just an indica-

tion; to get the best performance from the

bu

rner, the regulations should be made on the

basis of the effective requirements of the gen-

erator.

With 60Hz power frequency, the burner must

be

re-set, closing the air damper, so that the

amount of intake air is reduced.

4.2 RECOMMENDED NOZZLES

Monarch type R

Delavan type W (

up to 3,00 GPH)

Delavan type B (over 3,00 GPH)

Steinen type SS - S

Danfoss type B - S

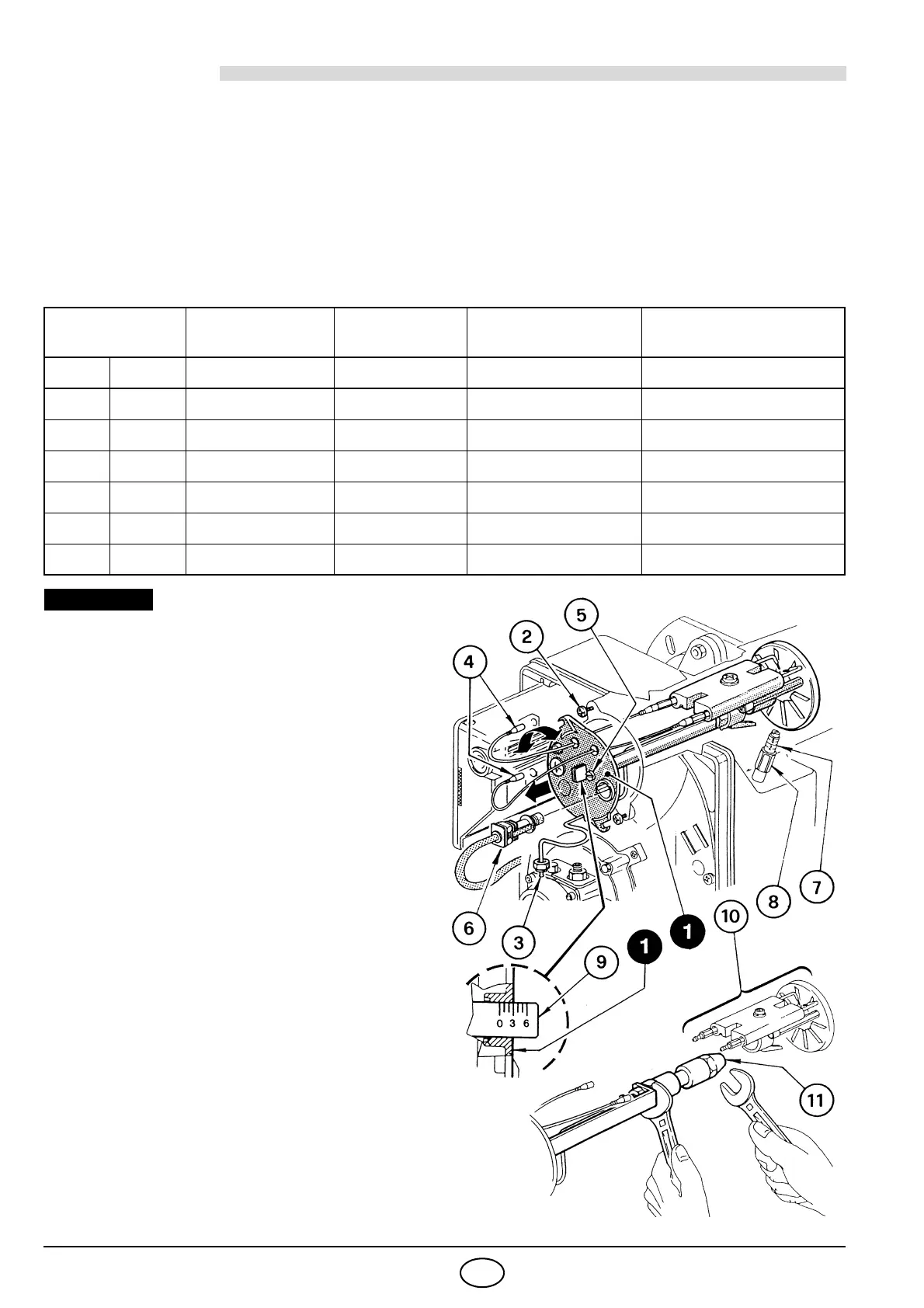

REPLACING NOZZLE, (see Fig. 11):

To replace nozzle, proceed as follows:

y Disconnect cables (4) from control box and pull

out the sensor llama (6).

y Unscrew nut (3), loosen screws (2) and remove

nozzle-holder assembly (1) by rotating slightly to

the right.

y Disconnect cables (4) from electrodes, unscrew

screws (3, Fig. 12, page 9) and remove the dif-

fuser disc support assembly (10) from nozzle-

hold

er assembly (1).

Loading...

Loading...