8 Rockwell Automation Publication 440G-UM001B-EN-P - May 2016

Chapter 1 General Description

With INACTIVE Guard Lock Monitoring:

In combination with a movable separating safety guard and the control system,

this safety device prevents dangerous machine movements from occurring

while the safety guard is open. A stop command is triggered if the safety guard

is opened during the dangerous machine function. The position of the guard

locking is not considered during this process.

Safety outputs (FO1A, FO1B) are enabled only when the locking bolt is sensed

in its extended position in the lock module (i.e, the guard door is closed and

the bolt is extended). In this mode, the status of the guard locking is not

considered.

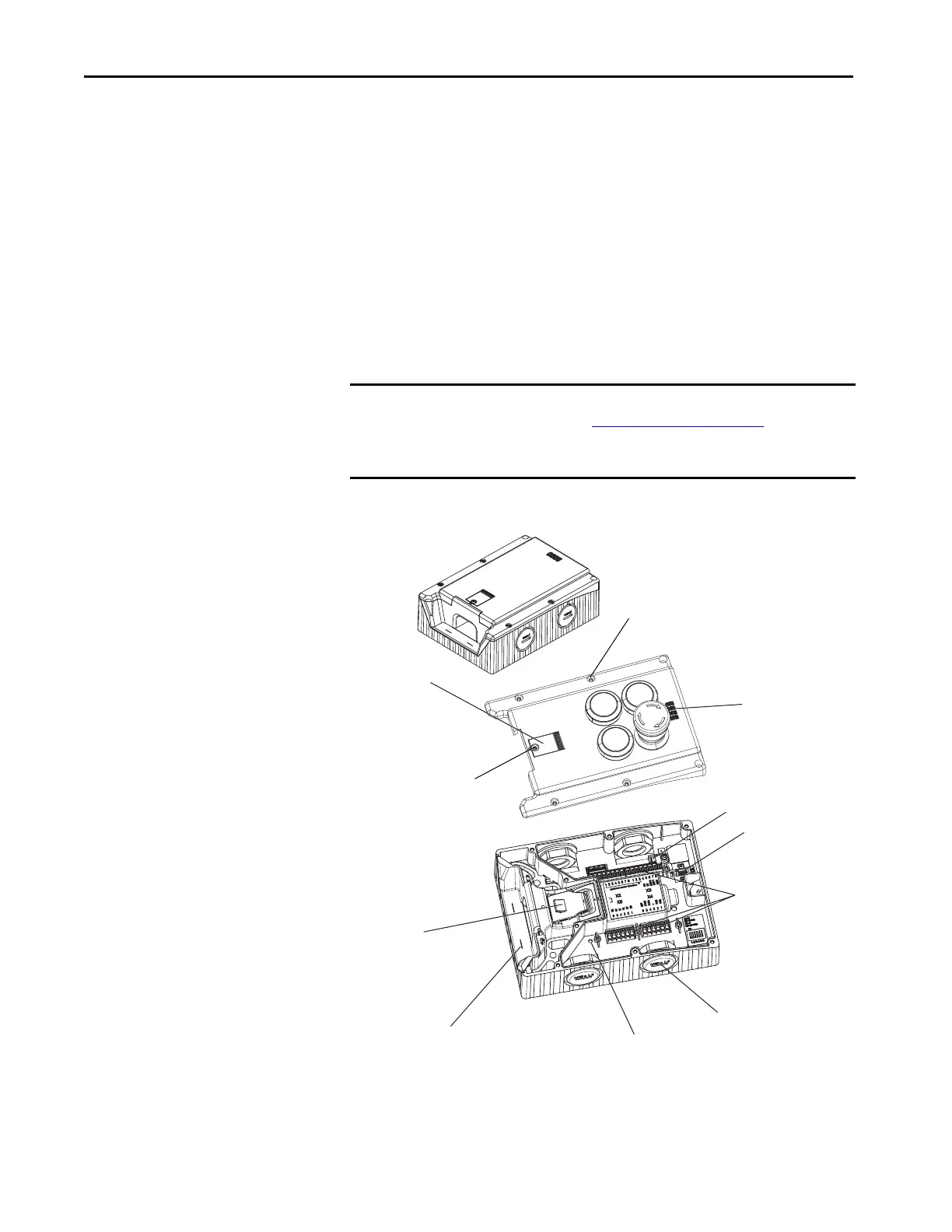

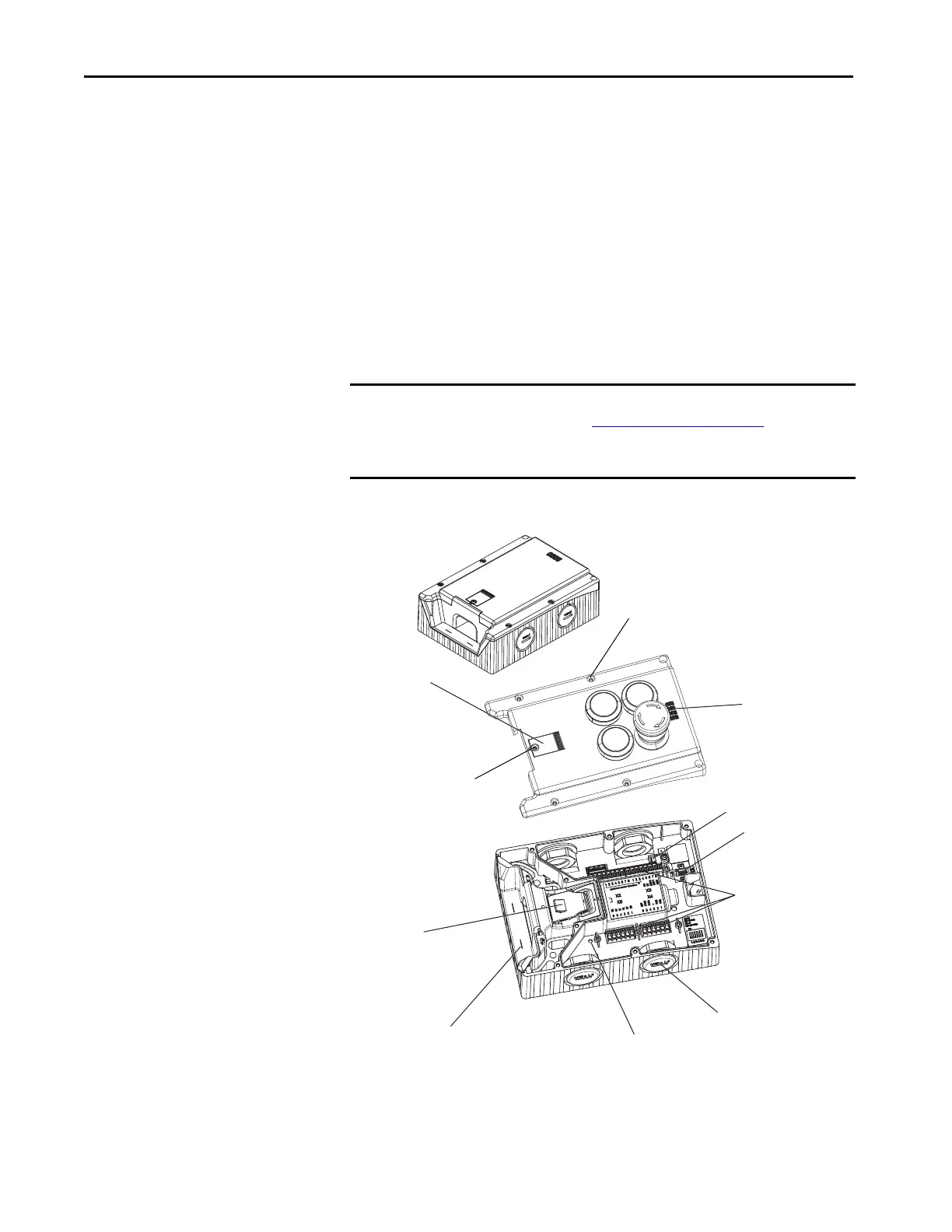

Assembly Overview

Figure 1 - Locking Module with Control Cover

* Apply to hardware revision B and higher.

IMPORTANT The safety outputs (FO1A, FO1B) are not enabled until a handle assembly

has been configured (see Handle Configuration

on page 15). After

configuration is completed, the lock module will only recognize the unique

code of the configured handle.

Manual Release

Cover

Terminals X2-X5

DIP Switches

Status/Diagnostic

Status Indicators

Locking Bar

Cable Entry M20 x 1.5 or

QD Connector (version-

dependent)

1 x Torx T8

6 x Torx T10

Marking for Maximum

Mounting Distance

Internal Reset*

Jumper*

Loading...

Loading...