Rockwell Automation Publication 2198-UM001D-EN-P - May 2014 147

Troubleshooting the Kinetix 5500 Drive System Chapter 7

Kinetix 5500 Capacitor Module Status Indicators

The capacitor module status indicator and module status (MS) connector are on

the front of the module. The module status connector is a relay output suitable

for wiring to the Logix5000 controller.

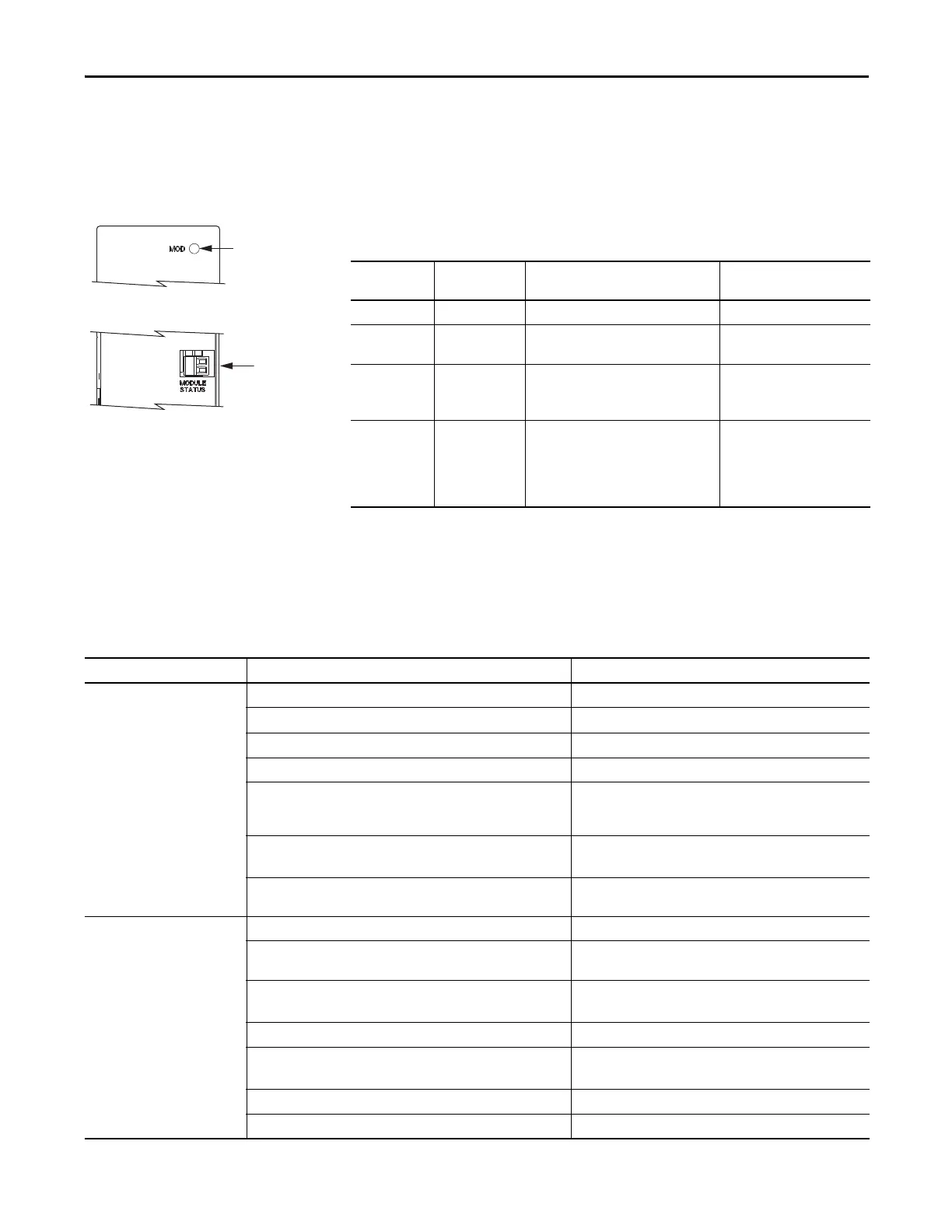

Table 66 - Module Status Indicator and Relay Output

General Troubleshooting

These conditions do not always result in a fault code, but can require

troubleshooting to improve performance.

Module Status

Indicator

Relay Output

(1)

(1) Wiring the module status relay output to the Logix5000 controller is optional.

Status Resolution

Steady Green Closed Bus is fully charged and no faults exist. N/A

Flashing Green Open

Control power is present and bus is waiting

to charge up.

N/A

Flashing Red Open

Recoverable fault

(precharge or overvoltage fault).

• Cycle control and bus power

• Verify that AC input meets

specificatons

Steady Red Open

Internal, non-recoverable fault condition

inside the module.

• Cycle control and bus power

• Verify that AC input meets

specificatons

• Replace the module if fault

persists

Module Status

Indicator

Kinetix 5500 Capacitor Module

Module Status

(MS) Connector

Table 67 - General Troubleshooting

Condition Potential Cause Possible Resolution

Axis or system is unstable.

The position feedback device is incorrect or open. Check wiring.

Unintentionally in Torque mode. Check to see what primary operation mode was programmed.

Motor tuning limits are set too high. Run Tune in the Logix Designer application.

Position loop gain or position controller accel/decel rate is improperly set. Run Tune in the Logix Designer application.

Improper grounding or shielding techniques are causing noise to be

transmitted into the position feedback or velocity command lines,

causing erratic axis movement.

Check wiring and ground.

Motor Select limit is incorrectly set (servo motor is not matched to axis

module).

• Check setups.

• Run Tune in the Logix Designer application.

Mechanical resonance.

Notch filter or output filter can be required (refer to Axis Properties

dialog box, Output tab in the Logix Designer application).

You cannot obtain the motor

acceleration/deceleration that you

want.

Torque Limit limits are set too low. Verify that torque limits are set properly.

Incorrect motor selected in configuration.

Select the correct motor and run Tune in the Logix Designer

application again.

The system inertia is excessive.

• Check motor size versus application need.

• Review servo system sizing.

The system friction torque is excessive. Check motor size versus application need.

Available current is insufficient to supply the correct accel/decel rate.

• Check motor size versus application need.

• Review servo system sizing.

Acceleration limit is incorrect. Verify limit settings and correct them, as necessary.

Velocity Limit limits are incorrect. Verify limit settings and correct them, as necessary.

Loading...

Loading...