Rockwell Automation Publication 2198-UM001D-EN-P - May 2014 163

Kinetix 5500 Safe Torque-off - Hardwired Safety Chapter 9

Safe Torque-off Wiring Requirements

The safe torque-off (STO) connector uses spring tension to secure the wire.

Depress the tab, along side each pin, to release the wire. Two rows of pins are

provided for drive-to-drive connections. Wire must be copper with 75 °C

(167 °F) minimum rating.

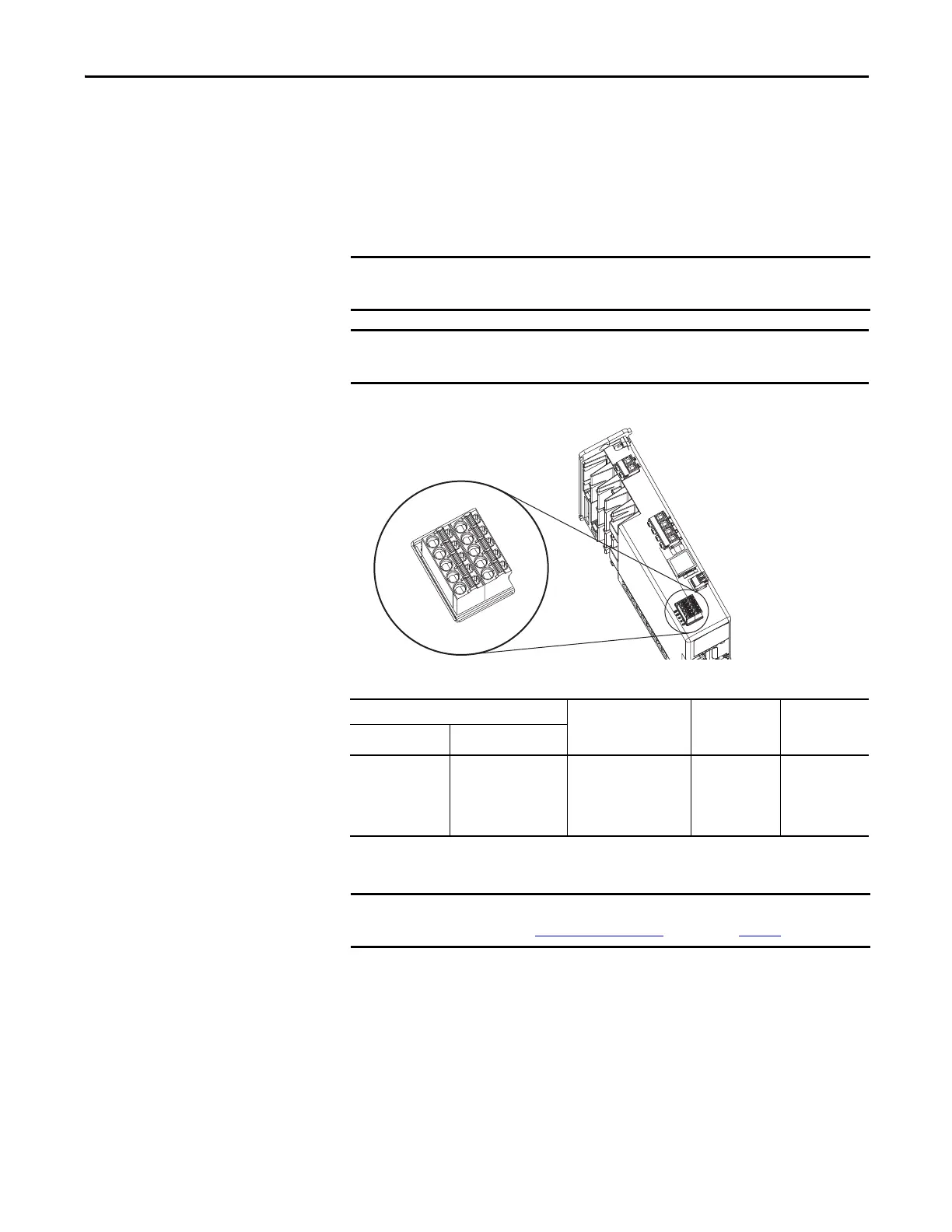

Figure 70 - Safe Torque-off (STO) Terminal Plug

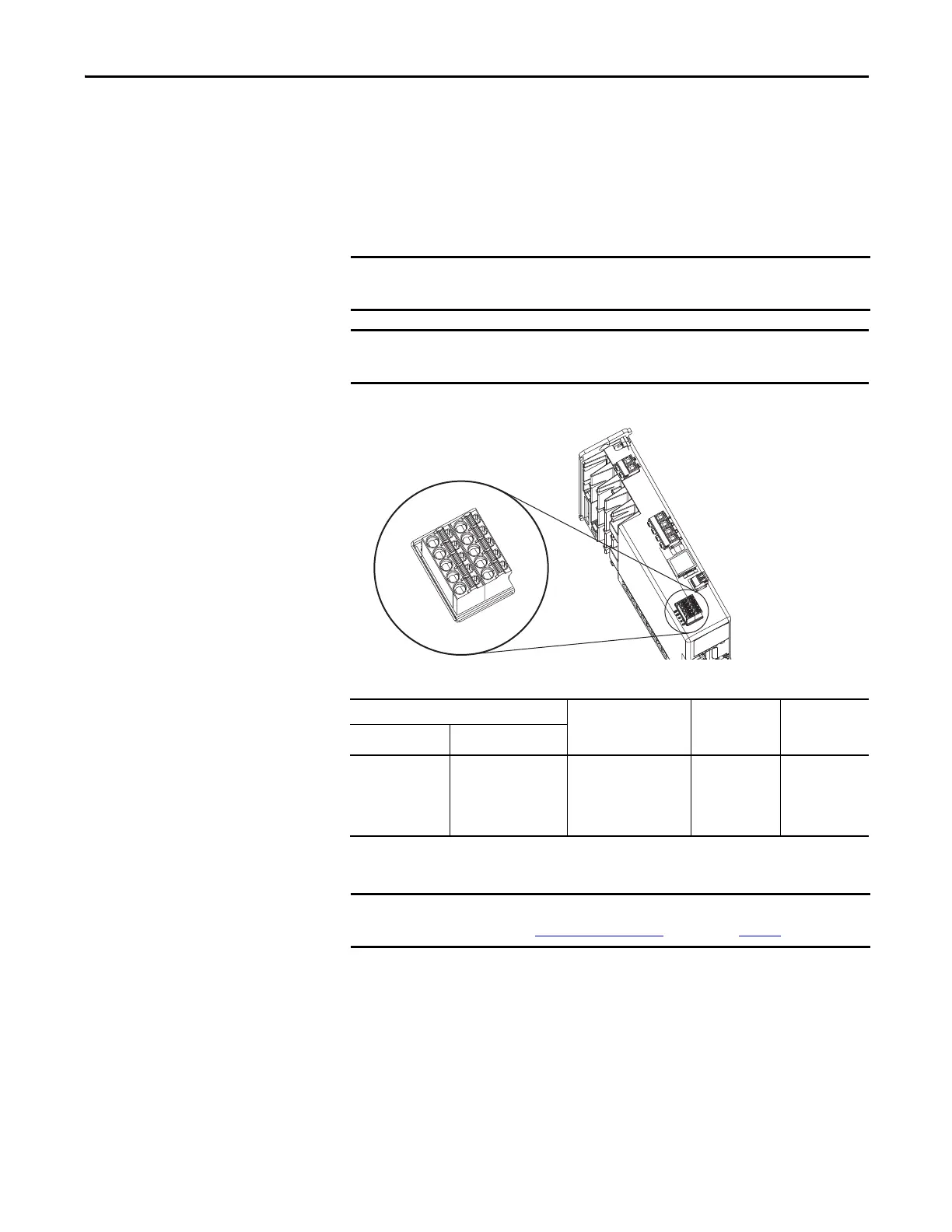

Table 76 - Safe Torque-off (STO) Terminal Plug Wiring

The National Electrical Code and local electrical codes take precedence over the

values and methods provided.

Stranded wires must terminate with ferrules to prevent short circuits, per table

D.7 of EN ISO 13849-2.

1

2

3

4

5

SB+

SB-

S1

SC

S2

Remove

For DC

Bus Only

Kinetix 5500 Drive

Top View

Safe Torque-off (STO) Connector Recommended Wire

Size

mm

2

(AWG)

Strip Length

mm (in.)

Torque Value

N•m (lb•in)

Pin Signal

STO-1

STO-2

STO-3

STO-4

STO-5

SB+

SB-

S1

SC

S2

1.5…0.2

(16…24)

10 (0.25) N/A

To improve system performance, run wires and cables in the wireways as

established in Establishing Noise Zones

beginning on page 39.

Loading...

Loading...