Component Test Procedures 2-3

Inspecting the Power Structure

1. Remove power from the drive. Refer to Removing Power from Drive on

page 3-3.

2. Remove the covers from the power structure. Refer to Removing the

Covers from the Power Structure on page 3-15.

3. Check components for burn marks, breakage or foil delamination on

circuit boards. Check all the boards on the power structure, including

those on the Output Power Modules and the Rectifying Module (if

present).

Replace any of these components without further testing if they show

evidence of burn marks, breakage or foil delamination.

Conducting Forward and

Reverse Biased Diode Tests

for Major Power Components

A forward biased diode test checks the semiconductor junctions between

the terminals and measures the voltage drop across those junctions. A

reverse biased diode test should find an open circuit, and the meter should

display a value close to zero (Ex. “.0L” = zero load).

Important: The actual voltage readings may vary depending upon your

equipment. If your readings are not near the indicated values in

the tables below, verify that the actual voltage measured is

consistent for the Rectifying module and Output Power

modules.

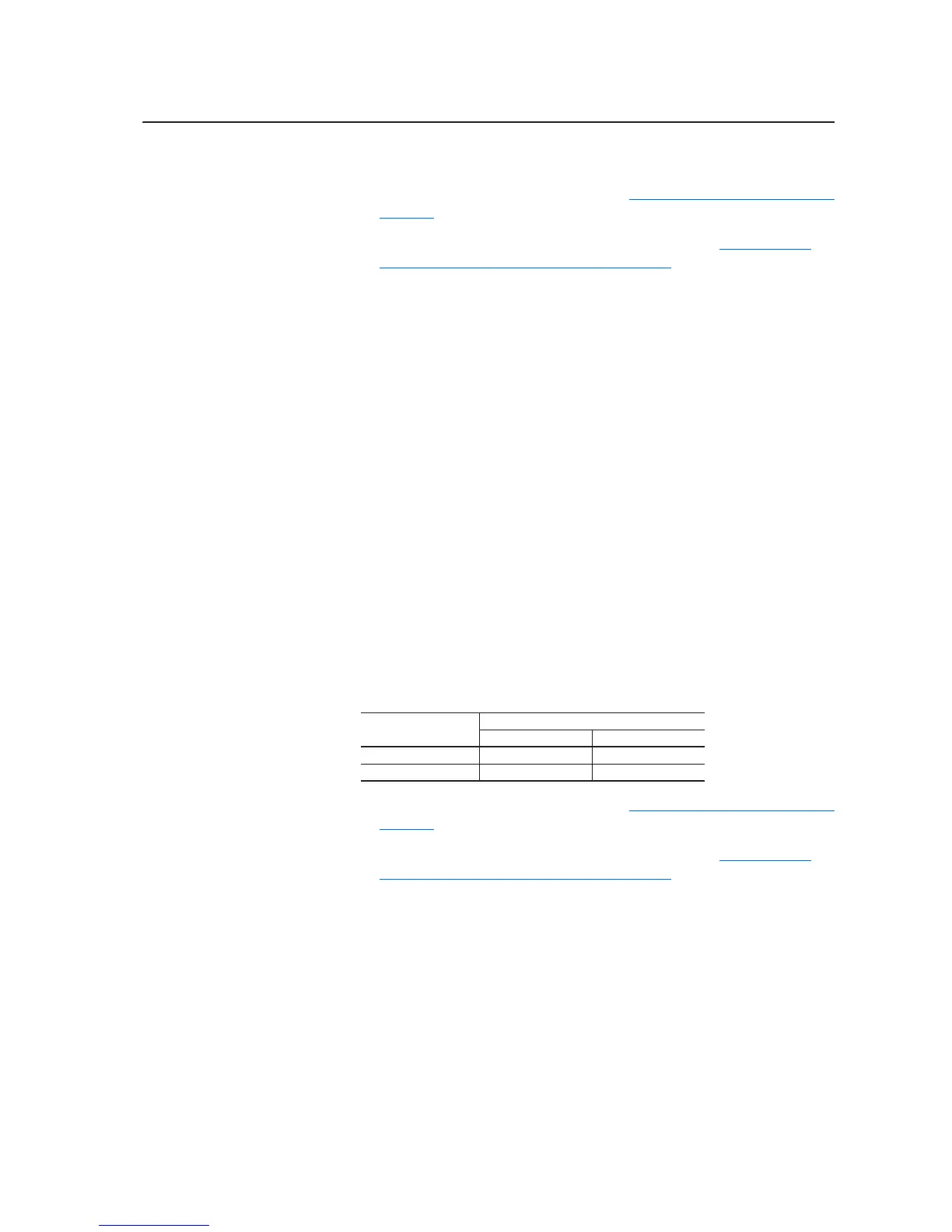

There is a series A and series B Rectifying circuit board. The tests you can

perform and the results of those tests vary depending on which series of

board is in your drive.

1. Remove power from the drive. Refer to Removing Power from Drive on

page 3-3.

2. Remove the covers from the power structure. Refer to Removing the

Covers from the Power Structure on page 3-15.

3. Disconnect the motor leads from the drive.

4. Conduct forward and reverse biased diode tests on the Rectifying

Module (if present) and the Output Power Modules.

Voltage Class

Rectifying Circuit Board Catalog String

Series A Series B

400/480V AC 20-VB00459 20-VB00461

600/690V AC 20-VB00460 20-VB00462

Loading...

Loading...