Reference Manual

00809-0100-4792, Rev CA

August 2010

B-9

Rosemount 1495, 1496

ASME MFC-3M-2004 Measurement of Fluid Flow in Pipes Using Orifice, Nozzle, and Venturi

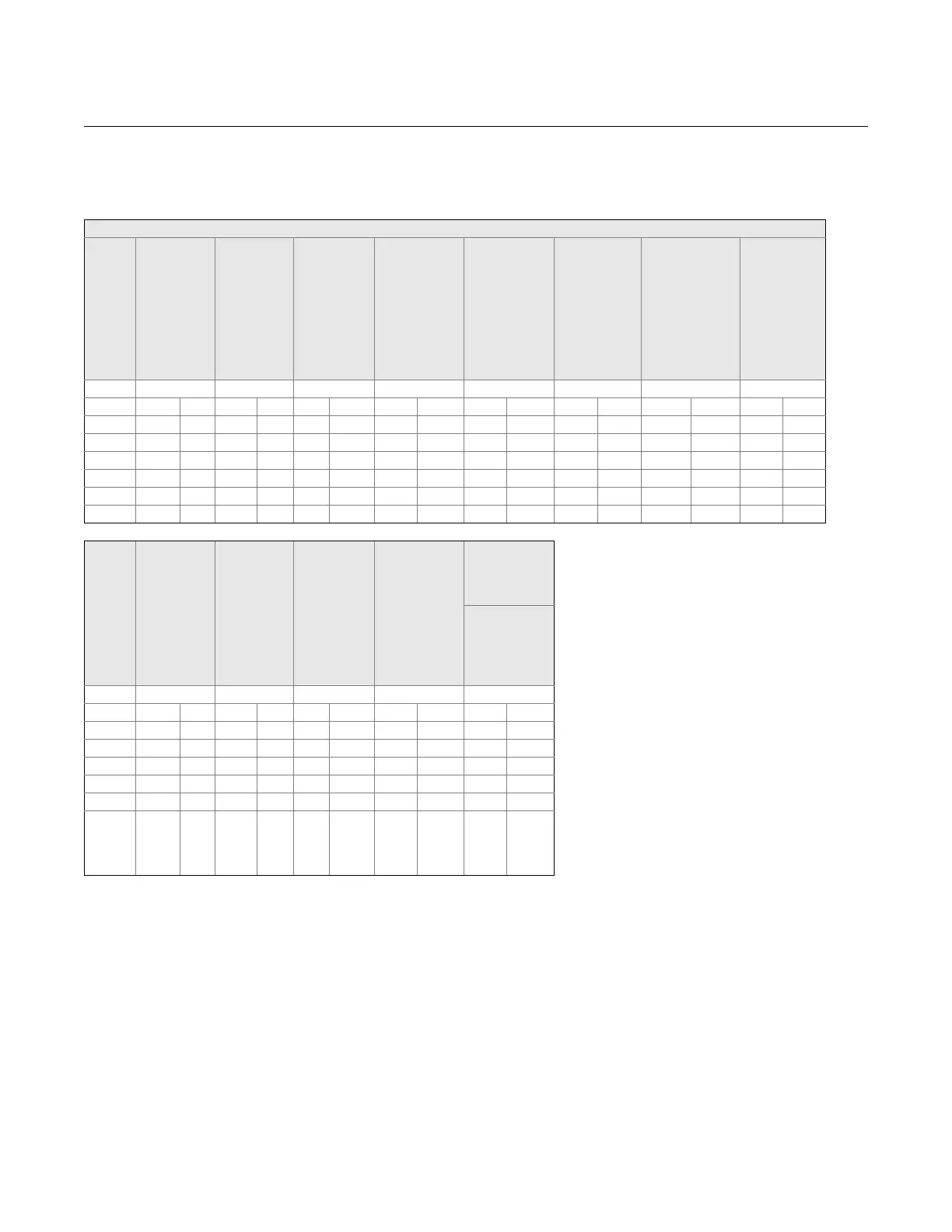

Table B-6. Required Straight Lengths Between Orifice Plates and Fittings Without Flow Conditioners

Upstream (Inlet) Side of Orifice Plate

Diam-

eter

Ratio

Single 90°

bend, Two

90° bends

in any

Plane:

S-Configu-

ration

(S>30D)

(1)

Two 90°

bends in

Same

Plane:

S-Configu-

ration

(30DS>10

D)

(1)

Two 90°

bends in

Same

Plane:

S-Configu-

ration

(10DS)

(1)

Two 90°

bends in

Perpendicular

Planes:

(30DS>5D)

(1)

Two 90

°

bends in

Perpendicular

Planes:

(5DS)

(1)(2)

Single 90°

Tee with or

without

Extension

Mitre 90°

Bend

Single 45°

Bend, Two 45°

Bends in Same

Plane:

S-Configuratio

n (S2D)

(1)

Concentric

Expander 2D

to D Over

Length of

1.5D to 3D

1 2 3 4 5 6 7 8 9

A B A B A B A B A B A B A B A B

0.20 6 3 10

(3)

10

(3)

19 18 34 17 3

(3)

7

(3)

5

(3)

0.40 16 3 10

(3)

10

(3)

44 18 50 25

(3)

3 30

(3)

5

(3)

0.50 22 9 18 10 22 10 44 18 75 34 19 9 30 18 8 5

0.60 42 13 30 18 42 18 44 18 65

(4)

25 29 18 30 18 9 5

0.67 44 20 44 18 44 20 44 20 60 18 36 18 44 18 12 6

0.75 44 20 44 18 44 22 44 20 75 18 44 18 44 18 13 8

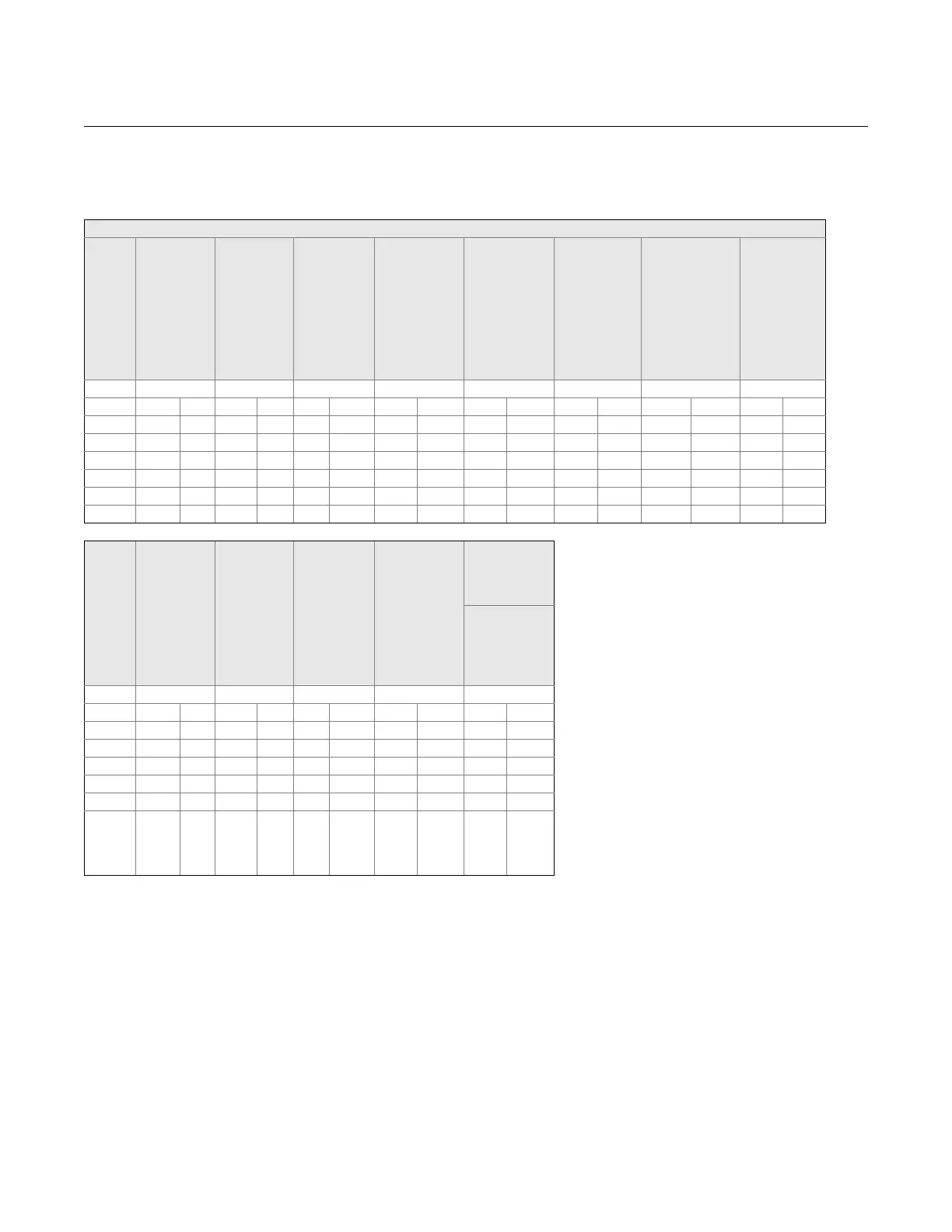

Diam-

eter

Ratio

Concentric

Expander

0.5D to D

Over

Length of D

to 2D

Full Bore

Ball Valve

or Gate

Valve Fully

Open

Abrupt

Symmet-

rical

Reduction

Thermometer

Pocket or

Well of

Diameter

0.03D

(5)(6)

Downstream

(outlet) Side

of the Orifice

Plate

Fittings

(Columns 2 to

11) and

Densitometer

Pocket

1 10 11 12 13 14

0.20 A B A B A B A B A B

0.40 6

(3)

12 6 30 15 5 3 4 2

0.50 12 8 12 6 30 15 5 3 6 3

0.60 20 9 12 6 30 15 5 3 6 3

0.67 26 11 14 7 30 15 5 3 7 3.5

0.75 28 14 18 9 30 15 5 3 7 3.5

Diam-

eter

Ratio

36 18 24 12 30 15 5 3 8 4

(1) S is the separation between the two bands measured from the downstream end of the curved portion of the upstream bend to the upstream end

of the curved portion of the downstream bend.

(2) This is not a good upstream installation; a flow conditioner should be used where possible.

(3) The straight length in each Column A gives zero additional uncertainty; data are not available for shorter straight lengths which could be used to

give the required straight lengths for each Column B.

(4) 95D is required for Re

D

X 10

6

if S < 2D.

(5) The installation of thermometer pockets or wells will not alter the required minimum upstream straight lengths for the other fittings.

(6) A thermometer pocket or well of diameter between 0.03D and 0.13D may be installed provided that the values in each Column A and B are

increased to 20 and 10 respectively. Such an installation is not, however, recommended.

GENERAL NOTES:

(a) Values expressed as multiples of internal diameter, D.

(b) The minimum straight lengths required are the lengths between various fittings located upstream or downstream of the orifice plate and the orifice

plate itself. Straight lengths shall be measured from the downstream end of the curved portion of the nearest (or only) bend or of the tee or the

downstream end of the curved or conical portion of the reducer or the expander.

(c) Most of the bends on which the lengths in this table are based had a radius of curvature equal to 1.5D.

(d) Column A for each fitting gives lengths corresponding to “zero additional uncertainty” values [see para. 2-5.2(c)].

(e) Column B for each fitting gives lengths corresponding to “0.5% additional uncertainty” values [see para. 2-5.2(d)].

30D S 5D

a

Loading...

Loading...