Seite /

Page

- 182 -

17.03.2005 / TPa

AT Fahrzeugserie

AT Vehicle-Series

© 2005

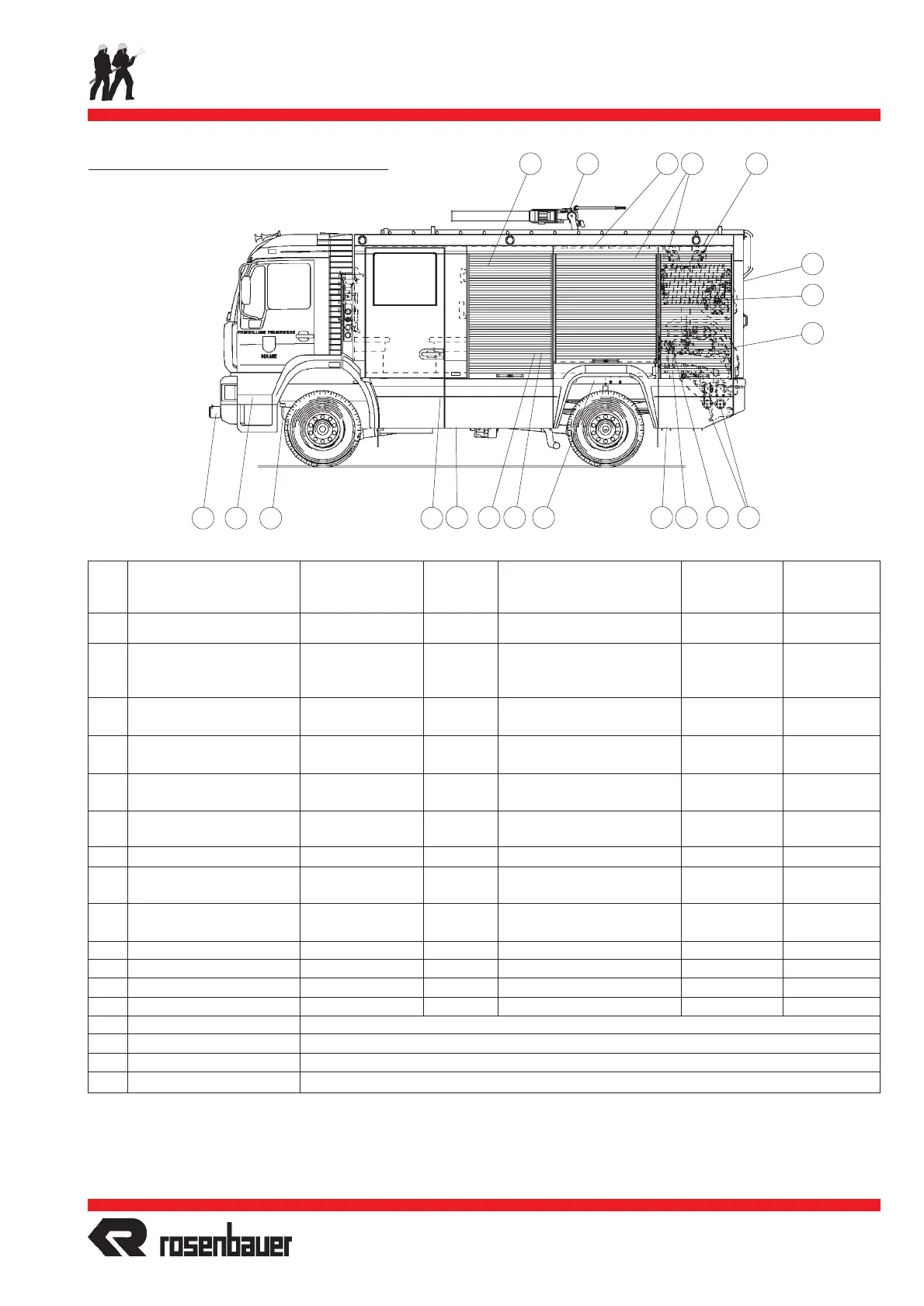

Wartung

Maintenance

D....... daily

M ...... monthly

H....... every six month

J ....... once a year

Service procedures - Maintenance chart

OIL CHANGE GREASE-

ITEM COMPONENT LUBRICANT VOLUME HOURS/TERM INTERVALL CHECK

1 Pump gear box

2

) transm. oil SAE 90 2 ltr. every 2 year 50-100 - **

2 Priming pump

1

) engine oil SAE 30 0.65 ltr. J 25-50 - **

Valve plates - - - - - J

V-belt - - - - - J

3 Bearing in NP-case *** Multi purp. grease - - - J -

All moving parts according NLGI II - - - - J

4 Propeller shaft Multi purp. grease - - - J -

according NLGI II

5 Shaft of Multi purp. grease - - - H -

pressure valves according NLGI II

6 Hose reel hub Multi purp. grease - - - M -

according NLGI II

7 Tank - inside walls - - - - - J

8 Guide bolt of Multi purp. grease - - - H -

crew room swivel board according NLGI II

9 Roller shutters Silicon paste "P" - - - H -

smooth

10 Light mast Special grease - - - J -

11 Gas struts - - - - - H

12 Compressor f. alarm sys. deliver. special oil - - - H -

13 Telescop supports Multi purp. grease - - - J H

14 Turret Please refer to separate operation manual

15 Equipment Please refer to manufacturers manual

16 Cable winch Please refer to manufacturers manual

17 Cassis Please refer to manufacturers manual

1

) SAE 30, API / SF, MIL-L-46152 B, FORD M2C 9011, GM 6048 M

2

) SAE 90, API / GL 4, MIL-L-2105, FORD M2C-28-B

** at oil leakage, ***

with NH-pump types only

14 7

1 2 5

6

4

9

13

17

11

11

3

16 12 8

109

1115

Loading...

Loading...