SCHEDULED MAINTENANCE

6‑10

OM1R-SM-GB01R

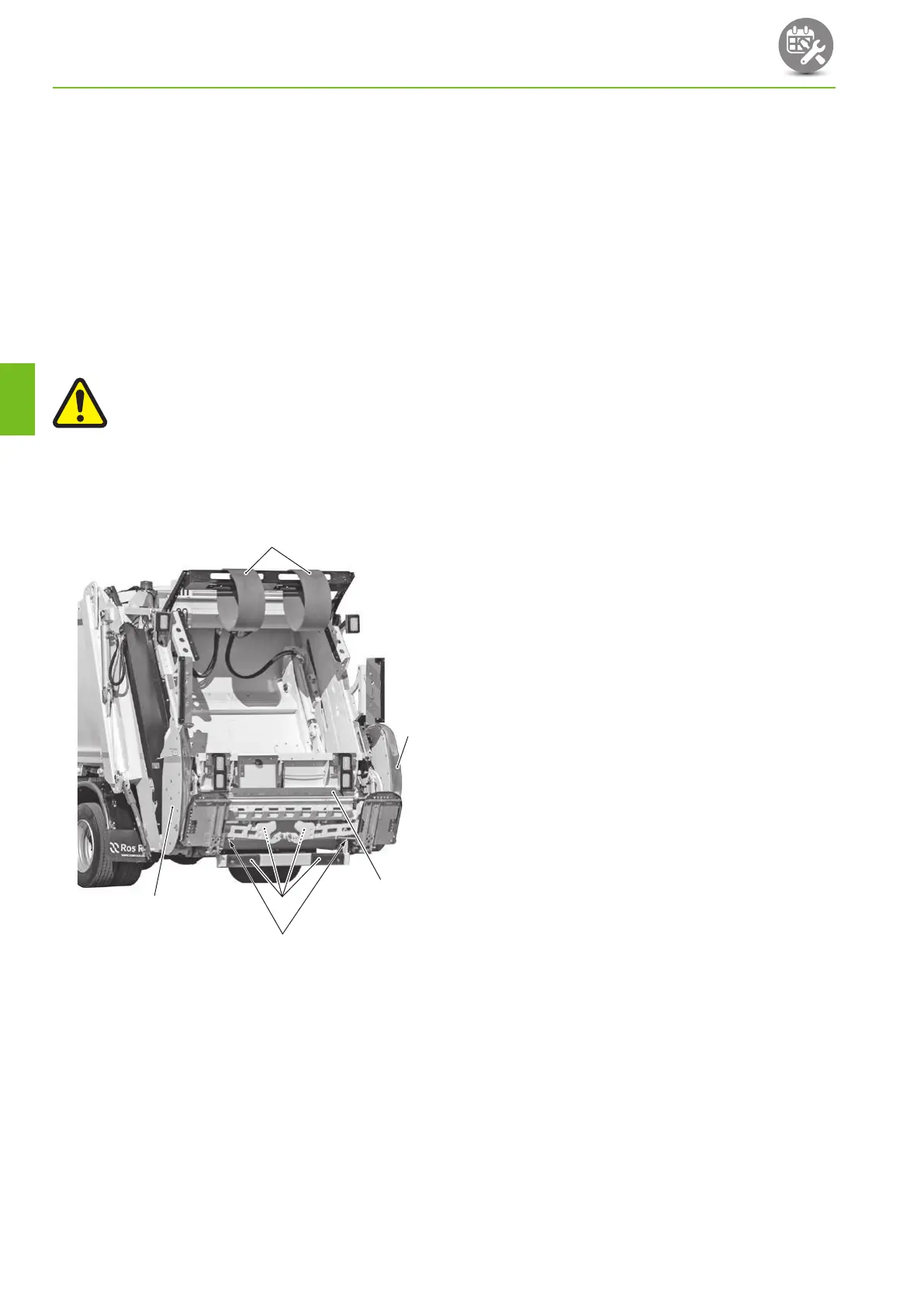

6.8.3 Waste container lifting

device maintenance

1. Grease all lubrication points (see ‘6.7 Lubrication’

on page 6‑6).

2. Check condition of all buffers and rubbers (2) and

replace if necessary.

3. Check that all safety guards (3) are fitted and in

good condition.

4. Check condition of DIN arm springs (4).

5. Check that all warning and advisory labels are

present, complete, legible and clean (see ‘3.5

Warning labels’ on page 3‑28).

WARNING:

NEVER OPERATE THE LIFTING DEVICE IF

ANY OF THE GUARDS ARE MISSING OR

DAMAGED.

6. Check the lifting device for any signs of undue

wear and/or damage.

7. Report any findings to supervision.

2

2

3

3

4

6.9 6-Week (300 operating

hours) service operations

The following service operations should be carried

out once every 6 weeks (300 operating hours) or

more frequently when the Refuse Collection Vehicle is

operating in severe conditions.

The following service checks should be carried out

in addition to the Daily service checks and Weekly

service operations.

1. Immobilise the vehicle (see ‘1.2 Immobilising

the vehicle prior to service procedures’ on page

1‑3).

6

Loading...

Loading...