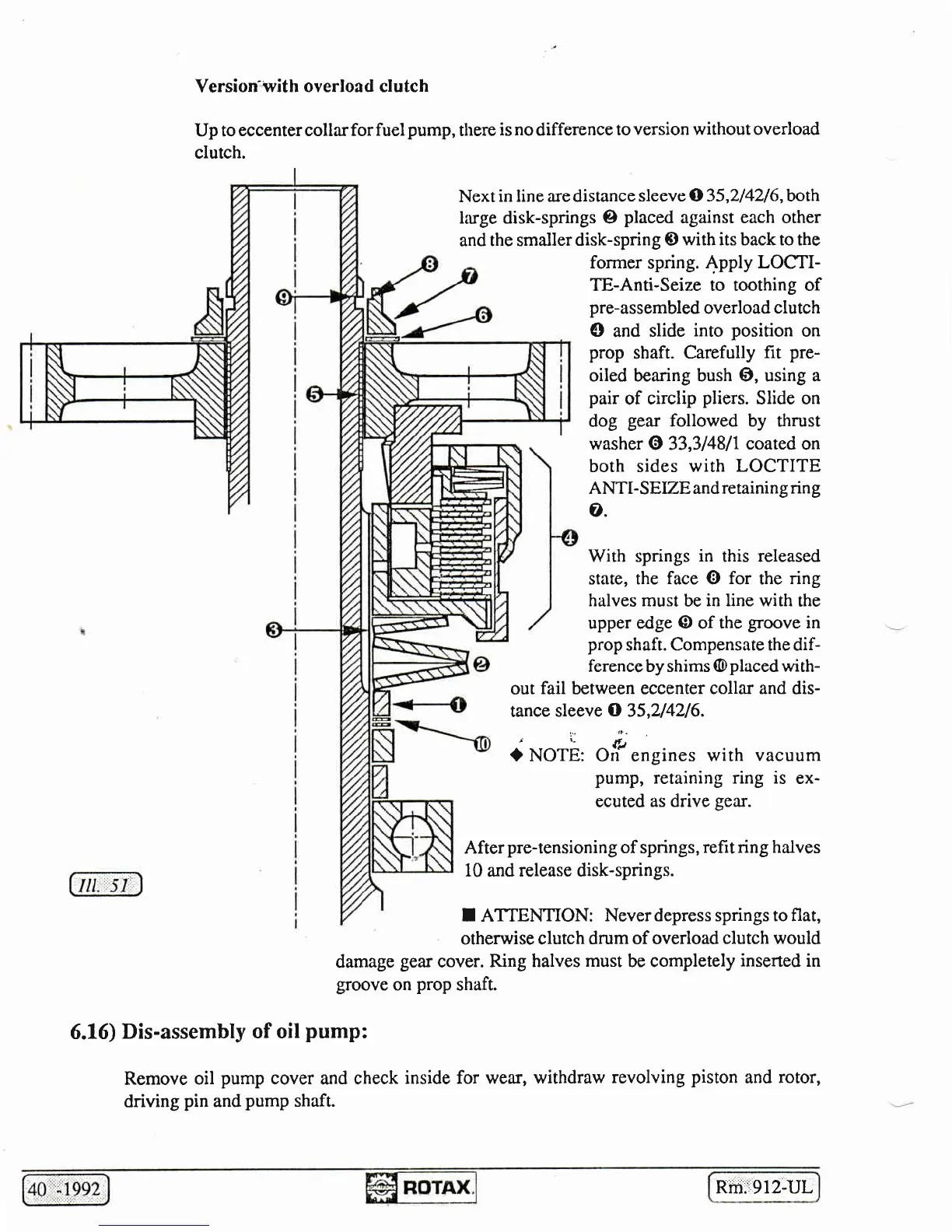

Versionwith

overload clutch

Up to

eccenter collar for

fuel

pump,

there

is no

difference

to

version without overload

clutch.

Next

in line are distance

sleeve O35,2/4216, both

liuge disk-springs I

placed

against each other

and

the smaller

disk-spring @

with its back to the

former spring.

4pply

LOCTI-

TE-Anti-Seize to toothing of

pre-assembled

overload clutch

O

and

slide

into

position

on

prop

shaft.

Carefully

fit

pre-

oiled bearing bush 6, using a

pair

of

circlip

pliers.

Slide on

dog

gear

followed by thrust

washer

@ 33,314811

coated

on

both sides with

LOCTITE

ANTI-SEZE and retaining rin

g

o.

With springs

in

this released

state, the

face

@

for

the

ring

halves must

be

in line with

the

upper edge

O

of

the

groove

in

prop

shaft. Compensate the dif-

ference by shims

(Dplaced

with-

out

fail between eccenter collar

and

dis-

tance

sleeve

O

35,2142/6.

|

'|-

J

r.

E,

t

NOTE:

Oil engines

with

vacuum

pump,

retaining ring is

ex-

ecuted

as drive

gear.

Afterpre-tensioning

of

springs,

refit ring halves

10

and

release disk-springs.

I ATTENTION:

Neverdepress springs toflat,

otherwise clutch

drum of overload

clutch would

damage

gear

cover.

Ring halves

must

be completely

inserted

in

groove

on

prop

shaft.

6.16)

Dis-assembly

of oil

pump:

Remove

oil

pump

cover

and check

inside for wear,

withdraw

revolving

piston

and

rotor,

driving

pin

and

pump

shaft.

Rm:'i912-UL

Loading...

Loading...