6.2L.4) Obscrvation of the oil temperature

For

placing

a temperature sensor, a tapped

hole M10 is

provided

in

the oil

pump

housing,

beside the oil

filter.

Pick-up and indicating

instrument

are the same as used

for

cylinder

head

temperature.

6.21.5)

Monitoring

of oil

pressure

The connection for

thc oil

pressure

indication

is

located on the oil

pump;

a

tapped

hole

U8"

-

27 NPT

for

pressure pick-up

VDO 360.081/0291012 is on the right side

of the

oil

pump.

Suitable

pressure

gauge

0

-

10

bar

(0

-

145

psi),

VDO 3501271/03U007.

6.22)

Electric starter

After

dis-assembly

of

starter check the

following:

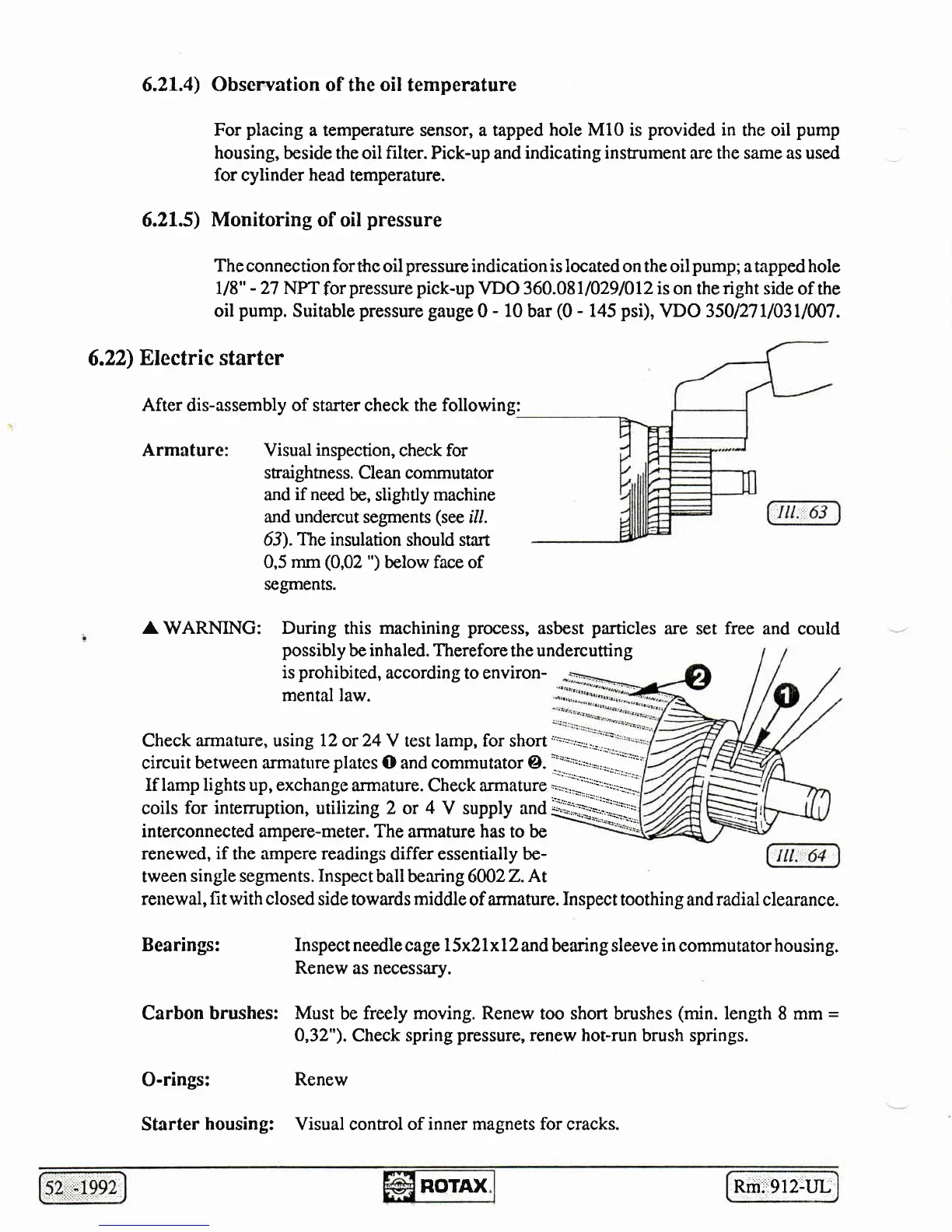

Armaturc: Visual

inspection,

check

for

straightness. Clean commutator

and

if need

be, slightly machine

and undercut

segments

(see

r//.

63). The insulation

should start

0,5

mm

(0,02

")

below face

of

segments.

A

WARNING:

During

this

machining

process,

asbest

particles

are set

free

and

could

possibly

be inhaled.

Therefore

the

undercutting

is

prohibited,

according to environ-

mental

law.

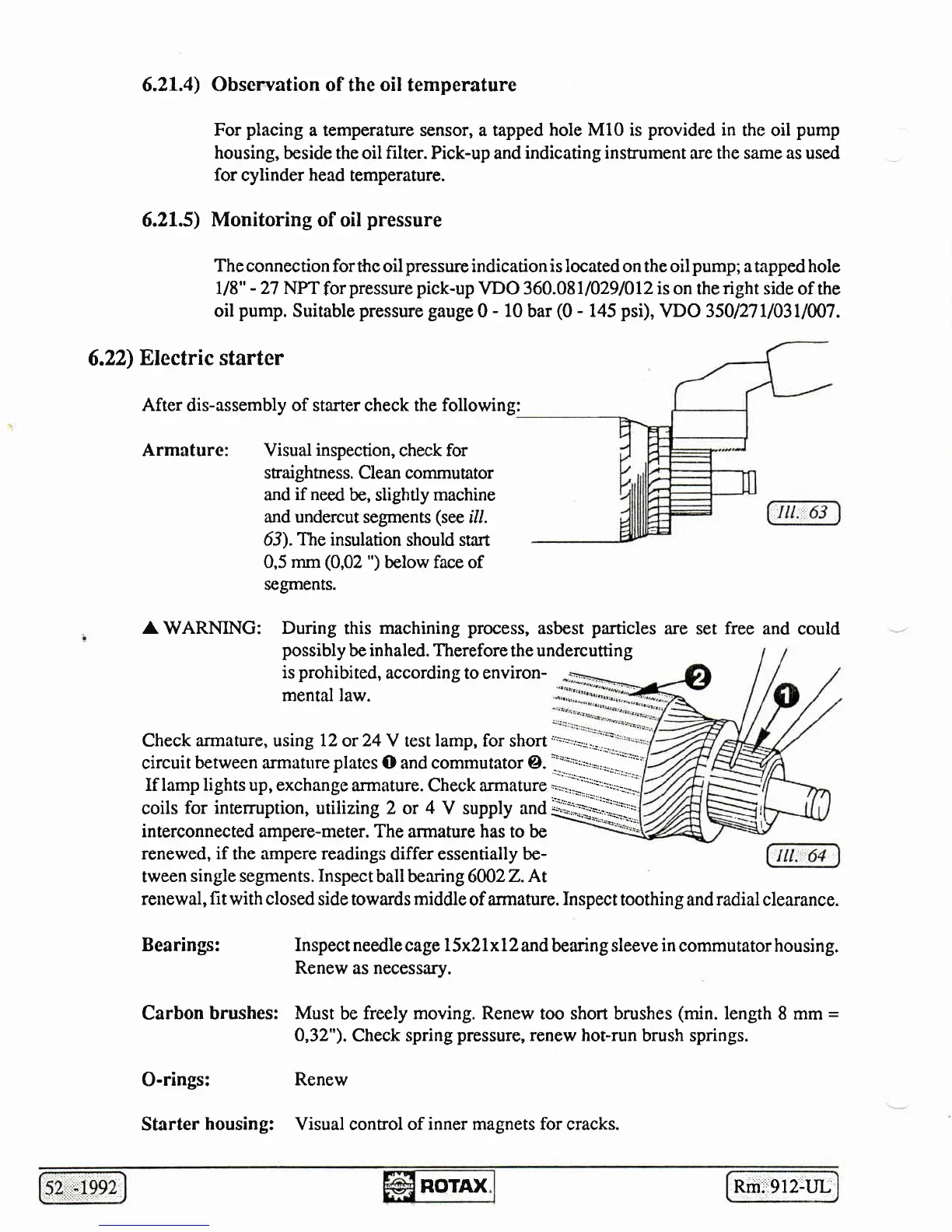

Check

armature,

using

12

or

24

V test

lamp,

for short

i1:-:r',1:i{,_:::*.

circuit

between :umature

plates

O and commutator O.

+r::r::rr.

If lamp lishts up. exchanse

a,,natu*. d##;.i"

::-$il::

If lamp lights up, exchange

annature.

Check

armature

=,,,...--

-"'-',=.'.=.r-.

coils

for intemrption,

utilizing 2

or

4

V

supply onA

*S;:..fi

interconnected

ampere-meter. The armature has to be

renewed, if

the

ampere readings

differ essentially be-

tween

single segments.

Inspect

ball bearing 6N22.

At

renewal,

fit

with closed

side towards

middle

of annature.

Inspect

toothing and radial

clearance.

Bearings: Inspect needle

cage

llx2lxl2and

bearing

sleeve in

commutator housing.

Renew

as necessary.

Carbon brushes:

Must

be

freely moving. Renew

too short brushes

(min.

length

8 mm

=

O,32").

Check spring

pressure,

renew hot-run

brush springs.

O-rings:

Renew

Starter

housing:

Visual control of

inner magnets for

cracks.

ROTAX

Rm:i:912:UL-

Loading...

Loading...