6.L7) Drive of

vacuuin

pump

On engines equipped

with vacuum

pump,

check

corresponding

ball- and needle

bearings,

drive

gearand

oil

seal,

andrenew

as

necessary.

SecureAllen

screw

M6x14

withLOCTITEZ2I.On

no

account change

length

of screw.

O NOTE:

Don't

pull

vacuum

pump

apart.

If

need

be, exchange

the complete

unit.

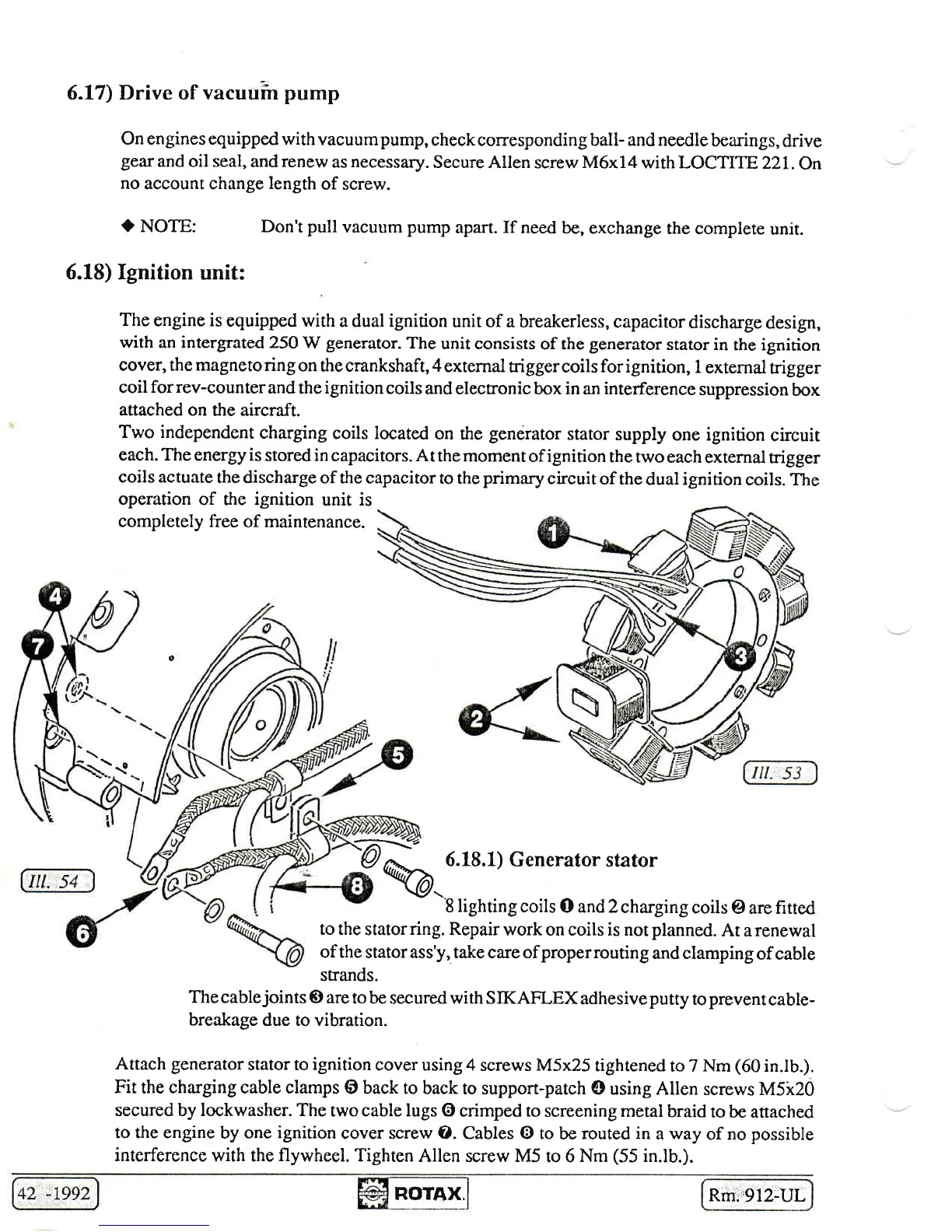

6.18) Ignition

unit:

)*

The

engine is

equipped with

a dual ignition

unit of

a breakerless,

capacitor

discharge

design,

with

an intergrated 250

W

generator.

The

unit consists

of the

generator

stator in

the ignition

cover, the magneto ring

on

the crankshaft, 4

external

trigger coils for ignition,

1

external

trigger

coil

for rev-counter

and

the

ignition

coils

and electronic box in

an

interference

suppression

box

attached on

the aircraft.

Two independent

charging

coils located

on

the

gendrator

stator

supply

one ignition

circuit

each. The energy is

stored

in

capacitors. At

the moment

of ignition

the

two each

external

trigger

coils actuate

the discharge

of the capacitor

to the

primary

circuit

of the

dual ignition

coils. The

operation

of the ignition

unit

is

completely free

of maintenance.

-Sz

U

n*

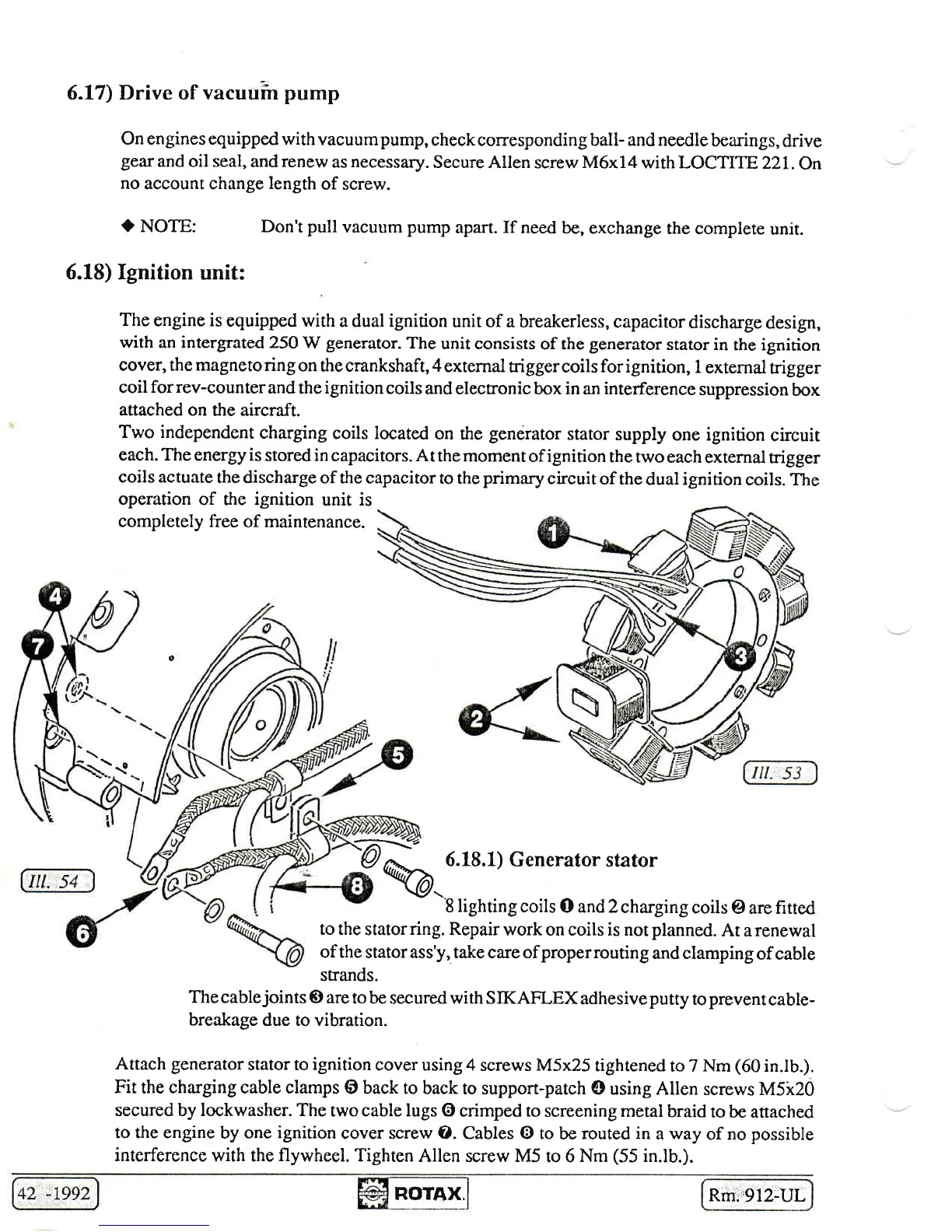

6.18.1) Generator

stator

%r ."''o'r'

\ttrrcr

arul rLarul

8 lighting coils

O and 2

charging

coils

@ arefitred

to the

statorring. Repair

work on coils is not

planned.

At

arenewal

of the

stator ass'y, take care of

properrouting

and clamping

of cable

strands.

Thecablejoints

@ aretobe

securedwith SIKAFLEXadhesiveputty

topreventcable-

breakage

due to vibration.

Attach generator

stator to ignition

cover using 4

screws M5x25

tightened

to 7

Nm

(60

in.lb.).

Fit

the charging cable clamps

@ back to back

to support-patch

@ using Allen

screws M5k20

secured by lockwasher. The

two

cable lugs G)

crimped to

screening metal

braid

to be anached

to the engine

by one

ignition

cover screw O. Cables @ to

be

routed in

a

way

of no

possible

interference

with the

flywheel.

Tighten

Allen screw M5

to 6

Nm

(55

in.lb.).

ROTAX.

Rmi"912-UL

Loading...

Loading...