7) Main assembly

of engine

gauge.

Dimension

axial clearance of crankshaft

Always

pay

special attention

to absolute cleanness.

Any

foreign

matter and smallest metallic

particle

in the oil circuit wouldberuinous

to thejournal

bearings and couldcauseengine

failureorconsiderable

reduction of service life.

INOTE:

All

O-rings, oil seals

and

gaskets

have to be

renewed

at re-assembly.

7.1,)

Crankcase

After

dimensions

are taken and

recorded,

split crankcase again.

Fit

the

right

crankcase half

(cast

mark

're')

on

trestle.

Place

greased

thrust

ring halves

serving as axial crankshaft

spacers

with coated side showing

towards outside,

into

crankcase.

Lubricate

bearing

halves

and

place

crankshaft ass'y fitted with timing

gear

into

position.

Turn crankshaft so

that timing

mark

on

timing

gear

aligns with crankcase

joint

face.

Check

axial clearance of crankshaft,

using

feeler

new

mm

(in)

wear limit mm

(in)

0,08

+

O,32

(0,m3 +

0,013) 0J0

(,@0)

Oil

ovemrnning

gear

50

T.

and

bearing bush and

fit

on

magneto

end of crankshaft. Apply

MOLYKOTE

GN

paste

to cams and lubricate bearings of camshaft.

Place

camshaft fitted

with

timing

gear, pump

gear

and

helical

gear

for rev-counter

(optional)

in

position.

Ensure

proper

coordination

of

marks on timing

gears,

thus marks are

parallel

now

to

joint

face.

Placepre-grease.loil

seal30x47

x7

ll,S,rollerbearingandretainingring

47x7,75 forprop

shaft in

position.

On

engines

with vacuum

pump,

fit

pre-assembled

drive

into

crankcase. Place

7

O-rings

9x2

in right

crankcase

half.

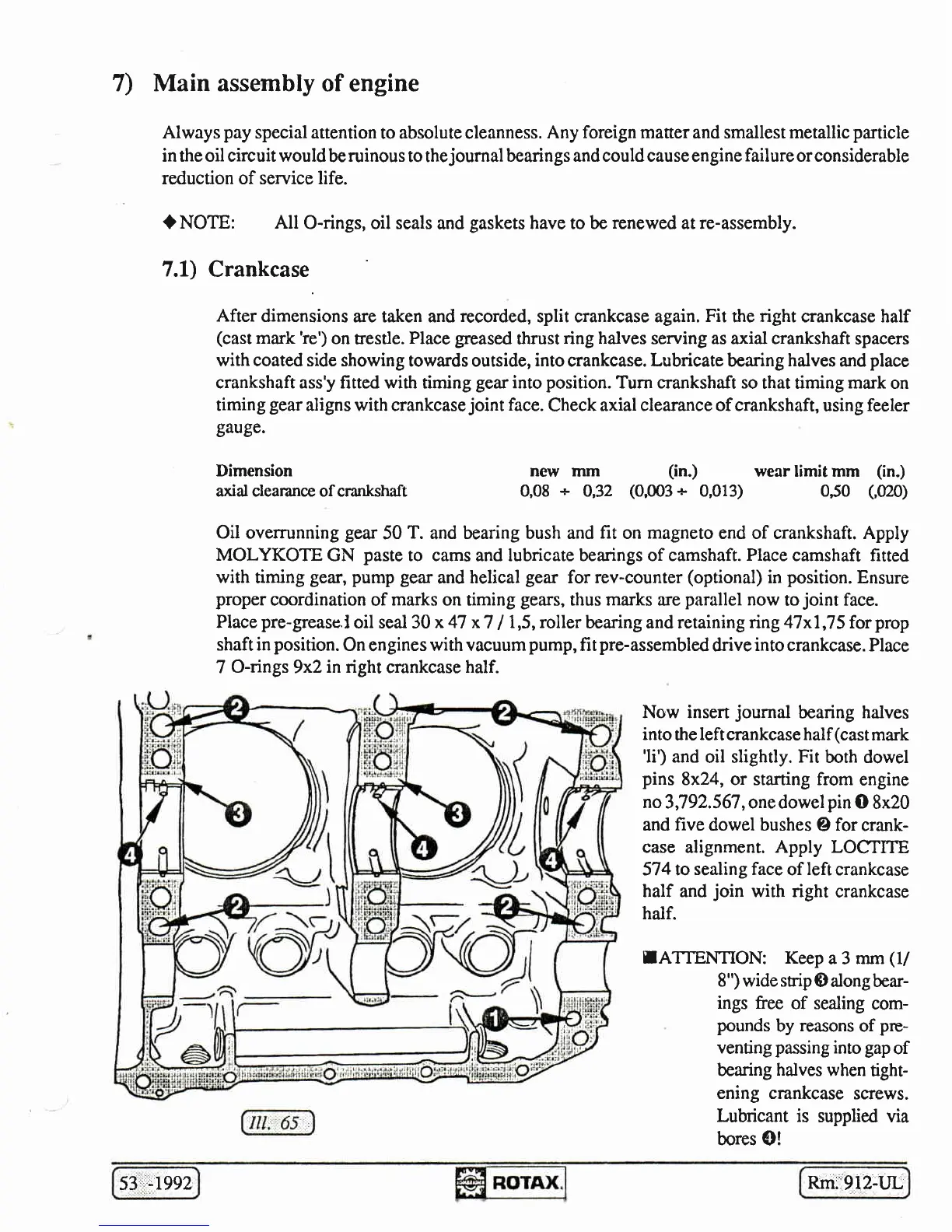

Now insert

journal

bearing

halves

into

the

leftcrankcase half

(castmark

'li')

and

oil slightly.

Fit

both dowel

pins

8x24, or starting from

engine

no3,792.567,

onedowel

pin

O

8x20

and

five

dowel bushes

O

for

crank-

case

alignment.

Apply LOCTITE

57

4

to

sealing face

of

left

crankcase

half and

join

with right

crankcase

half.

IATTENTION: Keep

a 3

mm

(1/

8") wide strip

0 along bear-

ings free

of sealing

com-

pounds

by

reasons

of

pre-

venting

passing

into

gap

of

bearing

halves

when

tight-

ening crankcase

screws.

Lubricant is

supplied via

bores

@!

53.t"t'"n'

Rm:'912:UL

Loading...

Loading...