4 x Set-up and installation

FA ROTEX HPSU compact 4 - 06/2015

33

4.6 Pressure test and filling the coolant circuit

Ɣ Perform pressure test with nitrogen.

– Use nitrogen 4.0 or higher.

– Maximum 40 bar.

Ɣ Afte

r leak search is complete, completely drain.

Ɣ Vacuu

m lines.

– Pressure to be achieved: 1 mbar absolute.

– Time: minimum 1 h

Ɣ Che

ck whether additional coolant is needed for primer filling,

fill where necessary.

Ɣ Open stop valve on exterior unit completely until the stop.

Tighten loosely.

Ɣ Reassemble valv

e caps.

Ɣ Check whether the storage tank temperature sensors t

DHW1

and t

DHW2

are inserted to a depth of 80 cm.

4.7 Filling the system with water

Do not fill the ROTEX HPSU compact until all installation activ-

ities have been completed, in the order shown as follows.

4.7.1 Checking the water quality and adjusting the

pressure gauge

Ɣ Observe the information on the water connection and water

quality in accordance with section 4.3.

The correct minimum pressure marking must be set on the

pressure

gauge installed by the customer before filling the

system for the first time:

Ɣ Ro

tate the pressure gauge glass in such a way that the

minimum pressure mark corresponds to the system

height +2 m (1 m water column = 0.1 bar).

4.7.2 Filling the hot water heat exchanger

Ɣ Open the shutoff valve for the cold water supply pipe.

Ɣ Open the hot water tap connections so that the draw-off

volume can be set as high as possible.

Ɣ Once water has bee

n discharged from the tap connections,

do not interrupt the cold water flow; this will ensure that the

heat exchanger will be fully vented and that any impurities or

residue will be discharged.

4.7.3 Filling the storage tank

See chapter 7.4.

4.7.4 Filling the heating system

See chapter 7.5.

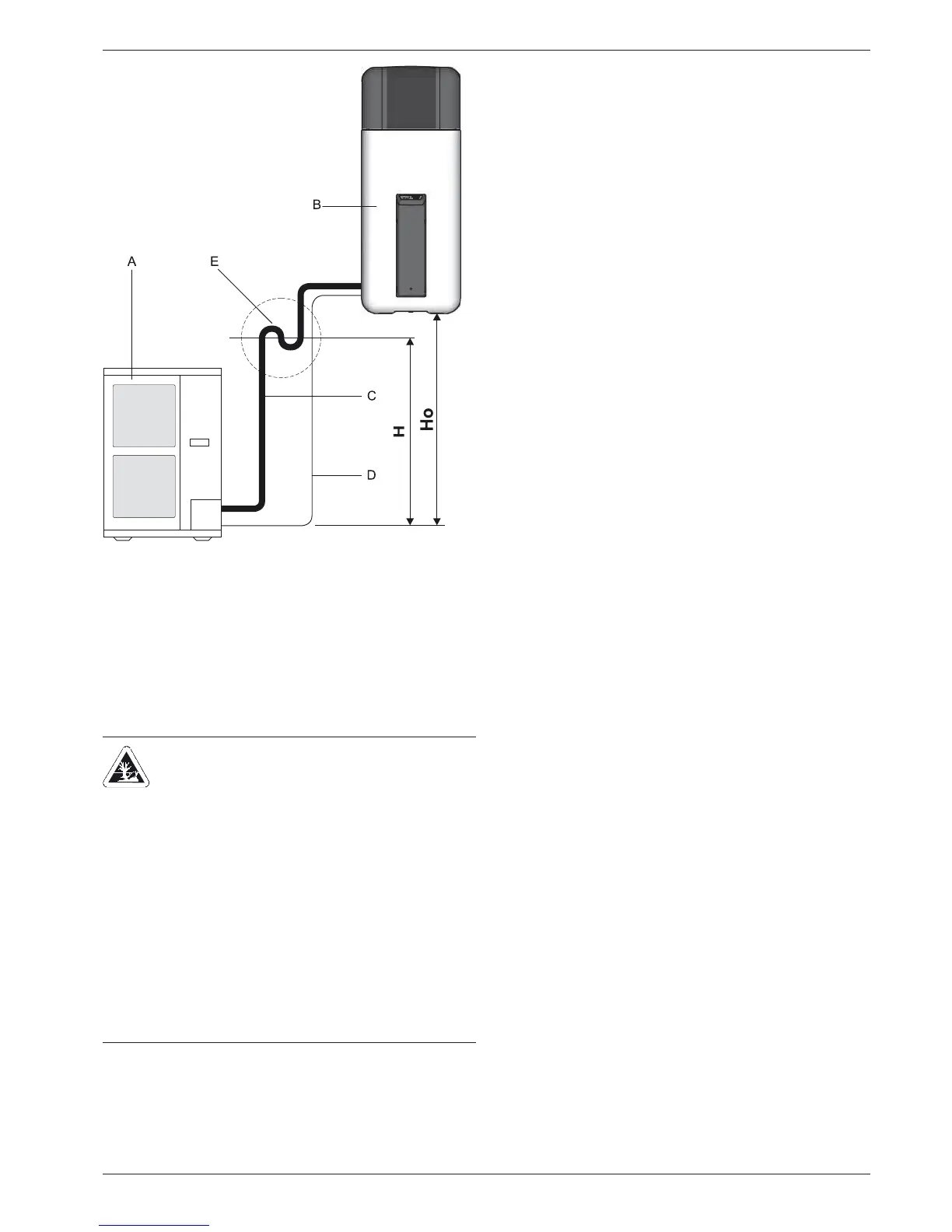

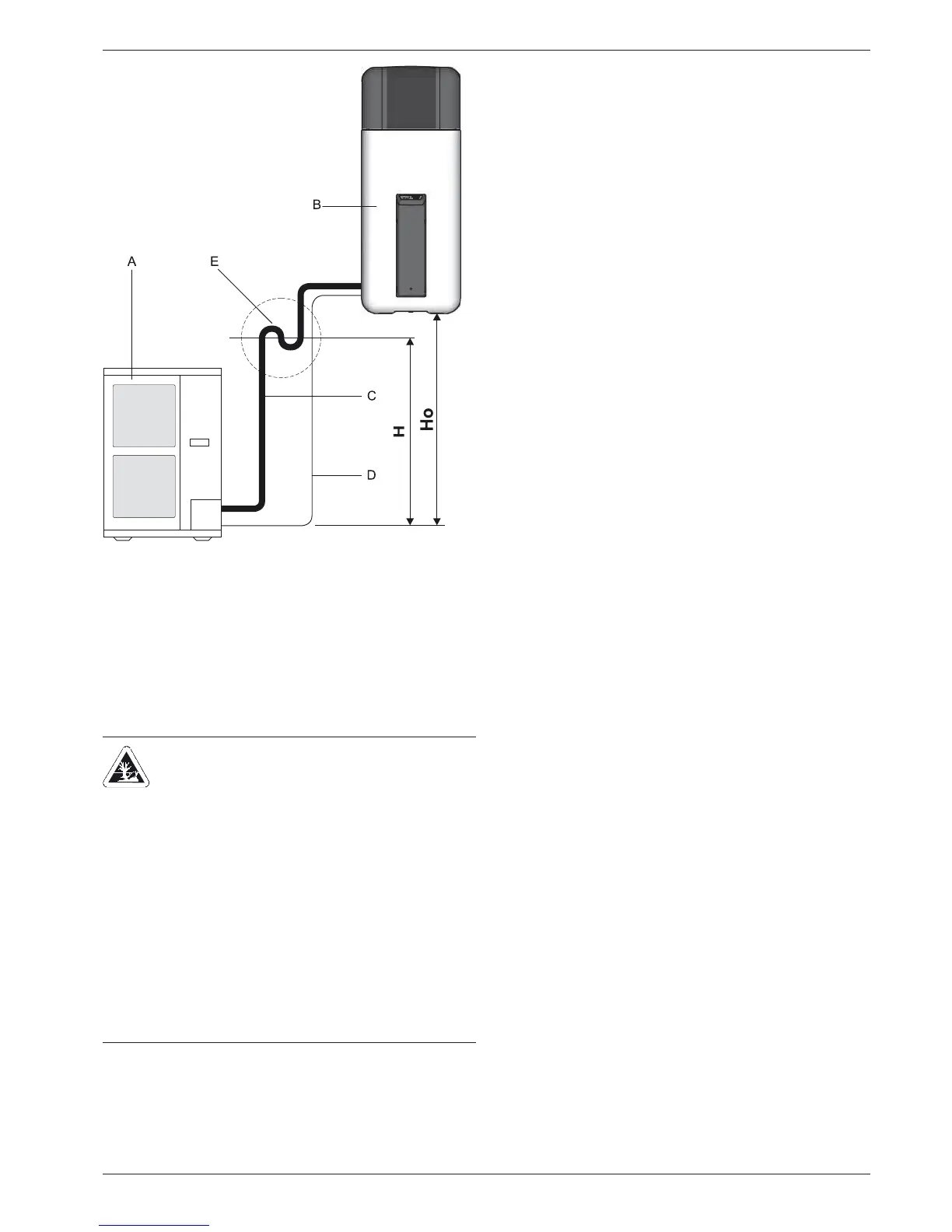

A Exterior heat pump unit (RRLQ)

B ROTEX HPSU compact

C Gas line

D Liquid line

E Oil trap arc

H Height to 1st oil trap (max. 10 m)

H

O

Height difference between heat pump exterior unit and heat pump

interior unit.

Fig. 4-37 Oil trap arc coolant line

RISK OF ENVIRONMENTAL DAMAGE!

Important information regarding the coolant used.

The complete heat pump system contains refrigerant

with fluorinated greenhouse gases which damage the

environment if released.

Coolant type: R410A

GWP* value: 2087,5

* GWP = Global Warning Potential

Ɣ Fill in the total coolant filling quantity on the

supplied lable on the heat pump exterior unit (for

information consult the installation instructions for

the heat pump exterior unit).

Ɣ Never all

ow coolant to be released into the atmos-

phere - always suction it off and recycle using a

suitable recycling device.

Loading...

Loading...