7.3

[en] 02/2014

Installation and operating manual - NK 31

Note

The oil ller neck is positioned so that overlling

of the screw compressor system is not possible.

Excess oil runs out of the ller neck again.

• Screw on the screw plug 1 rmly by hand.

• Switch on the system.

• Check the oil ller plug for leaks and replace

the O-ring if necessary.

• Carefully remove escaped, excess oil.

7.3 Oil change

Warning

Rotating, pressurized and hot components,

DANGER OF INJURY

The oil change may only be carried out at a

standstill and with the screw compressor system

completely discharged.

7.3.1 Oil change intervals

According to the specications of the system

manufacturer.

For the reference values for the screw compres-

sor compact module, see chapter 7.8 “Mainte-

nance intervals”.

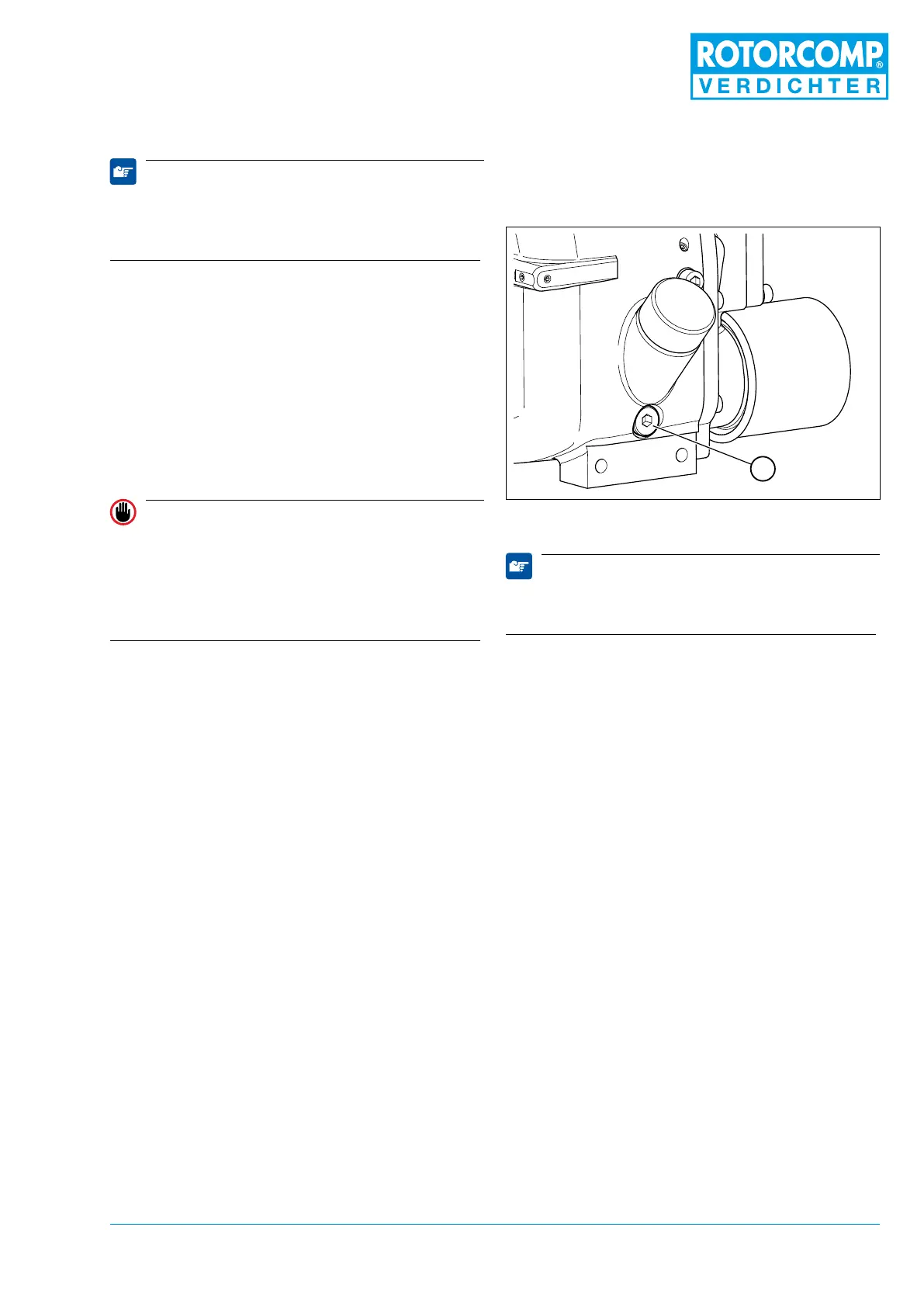

7.3.2 Oil drain points

The system should be at operating temperature

in this case.

Figure 7-2

Note

Dispose of the used oil according to the appli-

cable regulations.

• Switch off the screw compressor and then

secure it against being switched on again by

removing the main switch.

• Completely release the pressure in the screw

compressor system.

• Slowly screw off the screw plug on the oil ller

neck.

• Carefully unscrew the oil drain screw 1 and

catch the used oil in a suitable container.

• Clean the oil drain screw 1 and screw in again.

Loading...

Loading...