7.8

[en] 02/2014

Installation and operating manual - NK 31ROTORCOMP VERDICHTER

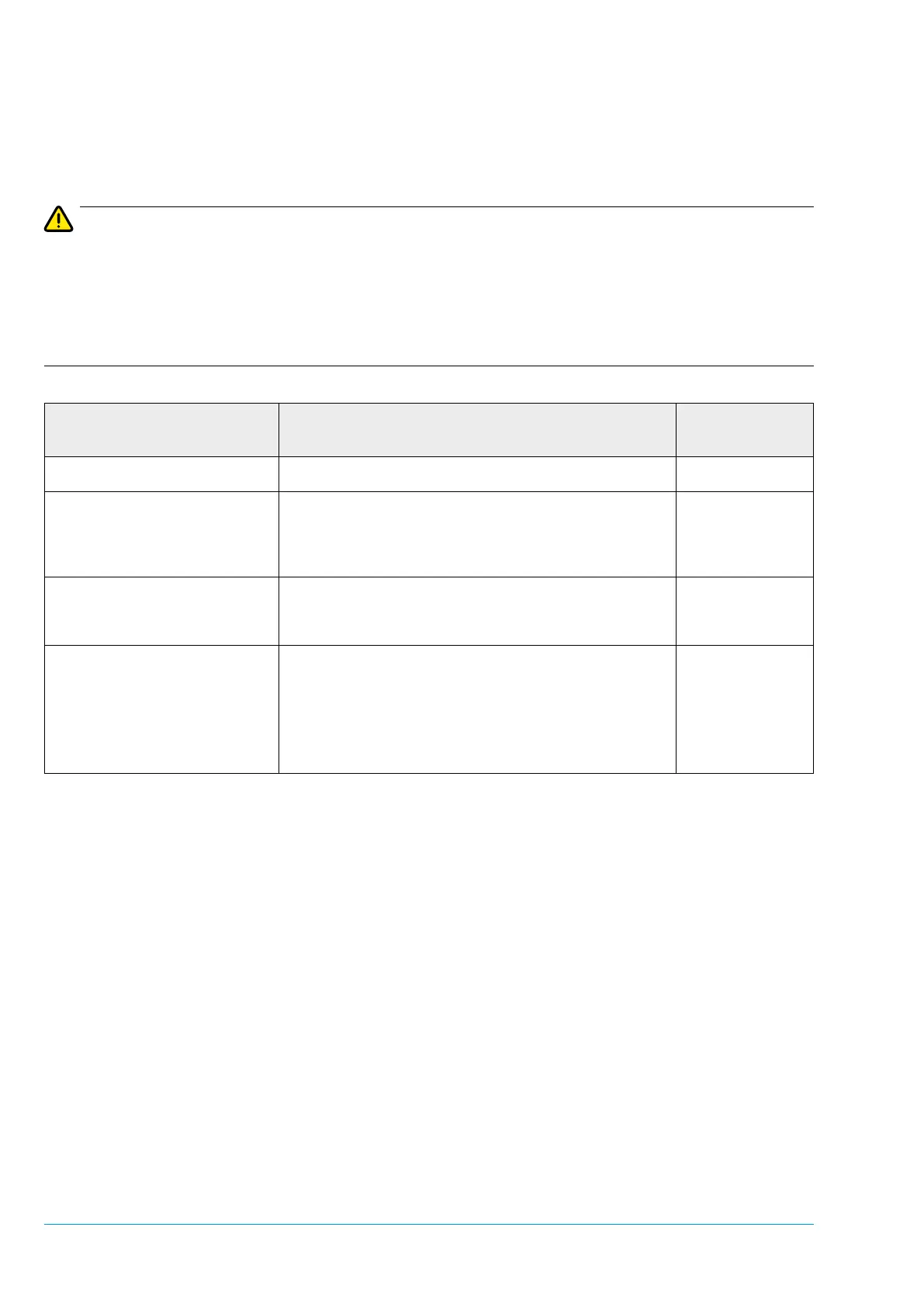

7.8 Maintenance intervals

Attention

The frequency of the maintenance intervals (oil change, replacement of oil lter, ne separator car-

tridge and air lter element) varies depending on the application and the operating parameters.

Depending on the design of the system, maintenance interval should therefore be specied by the

compressor manufacturer. These must be given priority. It is advisable to conclude a maintenance

agreement. The following table provides an overview of the reference value for the NK 31 screw com-

pressor module.

Maintenance intervals

(Bh = operating hours)

Maintenance work See chapter

Before commissioning Check oil level in separator tank 7.2

Once after 50 Bh Check oil level in separator tank

Tighten all screw pipe ttings and electrical

screw terminal ttings;

check all other connections for rm seating

7.2

Every 100 Bh Check oil level in separator tank,

top up in case of oil shortage

Check maintenance indicator

7.2

Every 1,000 - 6,000 Bh

depending on application

Recommendation:

every 12 months

Replace ne separator cartridge

Carry out oil change

Replace oil lter

Replace lter element in intake air lter

Check system for leaks

System inspection.

7.5.2

7.3

7.4.2

7.6.2

Loading...

Loading...