2 IQ3 manual – Section: Introduction

Table of Contents

1. Introduction _____________________________3

2. Preparing the Drive Bush _________________4

2.1 Thrust Compensators All Sizes ...............4

2.2 Disassembly of bearing assembly:

IQ10 – IQ35 .............................5

2.3 Reassembly:

IQ10 – IQ35 .............................5

2.4 Disassembly of bearing assembly:

IQ40 – IQ95 ............................6

2.5 Reassembly:

IQ40 – IQ95 ............................6

3. Mounting the Actuator __________________7

4. Fitting the Thrust Compensator __________8

4.1 Fitting the Actuator and Thrust Compensator as a

combined Unit: IQ10 – IQ35 .................8

4.2 Fitting Thrust Compensator to Valve Actuator:

IQ40 – IQ95 .............................8

5. Weights _________________________________9

WARNING:

This document must be read in

conjunction with the IQ Instructions for Safe

Use, Installation, Basic Setup and Maintenance

Manual (PUB002-039).

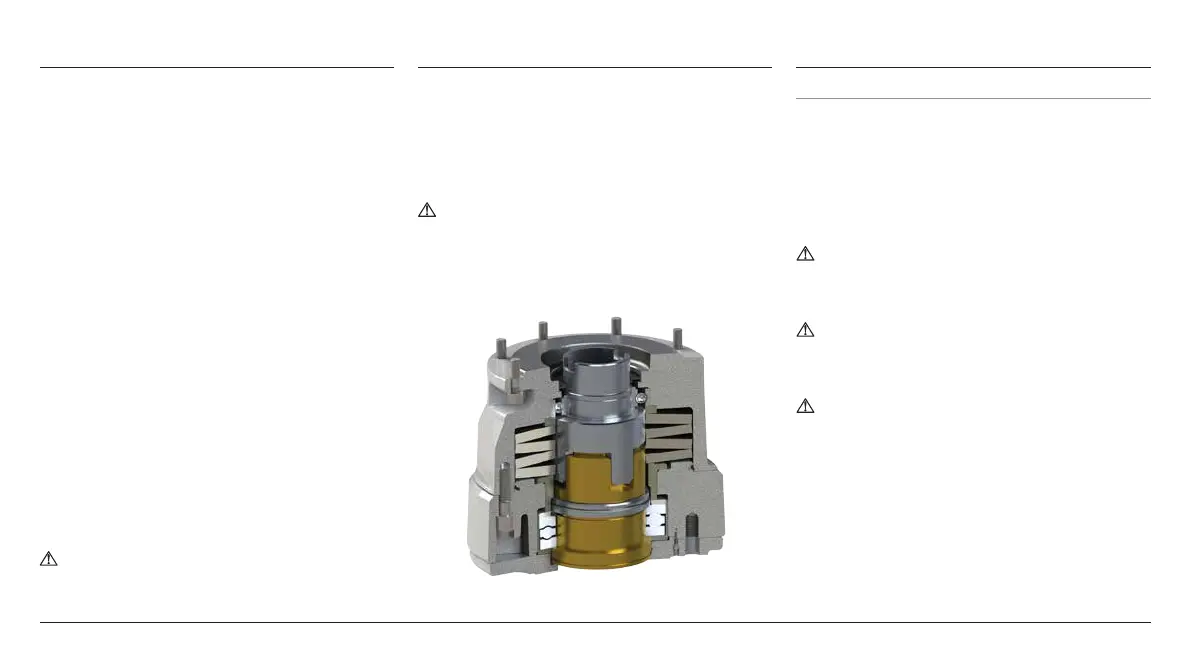

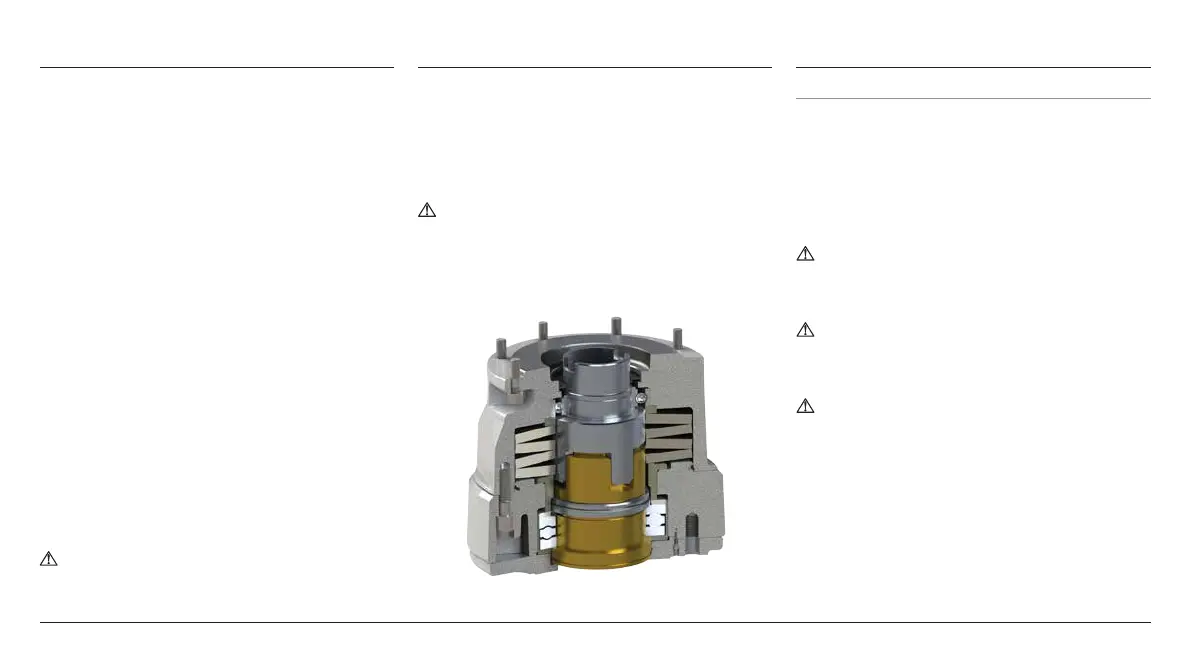

1. Introduction

The thrust compensator assembly is designed to

absorb excess thrust being delivered to the valve

structure as the result of stem expansion due to

temperature variation or high speed operation. In

addition, it is designed to maintain sufficient thrust

to retain valve closed position sealing on cooling and

contraction.

CAUTION: Each compensator is individually

configured for the specific, individual valve details

provided. It is therefore mandatory that each

actuator-compensator assembly remains paired

and is fitted only to the intended valve as specified

with the enquiry/order.

Fig. 1.1 Rotork Thrust Compensator

2. Preparing the Drive Bush

2.1 Thrust Compensators All Sizes

Place the thrust compensator with the base plate (2)

facing upwards. Remove the 4 cap-headed screws (1)

holding the base plate (2) in place and remove the base

plate (2) to gain access to the drive bush assembly (3).

Remove the drive bush assembly (3) complete with

its bearing assembly from the thrust compensator

housing. Before machining the drive bush, the bearings

and O-rings must be removed.

WARNING: Do not remove or tamper with

recessed cap-headed screws(*). Adjustment or

removal may result in application failure and/or

injury.

CAUTION: Failure to remove the bearing and

O-rings from the drive bush prior to machining

may result in damage to the bearing or O-ring

components.

WARNING: Component assembly and mass may

present a finger trap hazard.

Loading...

Loading...