6 IQ3 manual – Section: Fitting the Thrust Compensator

4. Fitting the Thrust

Compensator

4.1 Fitting the Actuator and Thrust

Compensator as a combined

Unit: IQ10 – IQ35

Fit the machined drive bush into the

thrust compensator as previously

described, lower the actuator onto

the threaded valve stem, engage hand

operation and wind the hand wheel to

engage the drive bush onto the stem.

Continue winding until the actuator

is fully lowered onto the valve flange.

Wind two further turns, fit securing

bolts and tighten fully to the required

torque indicated in PUB002-039 Fig.

6.1.3.

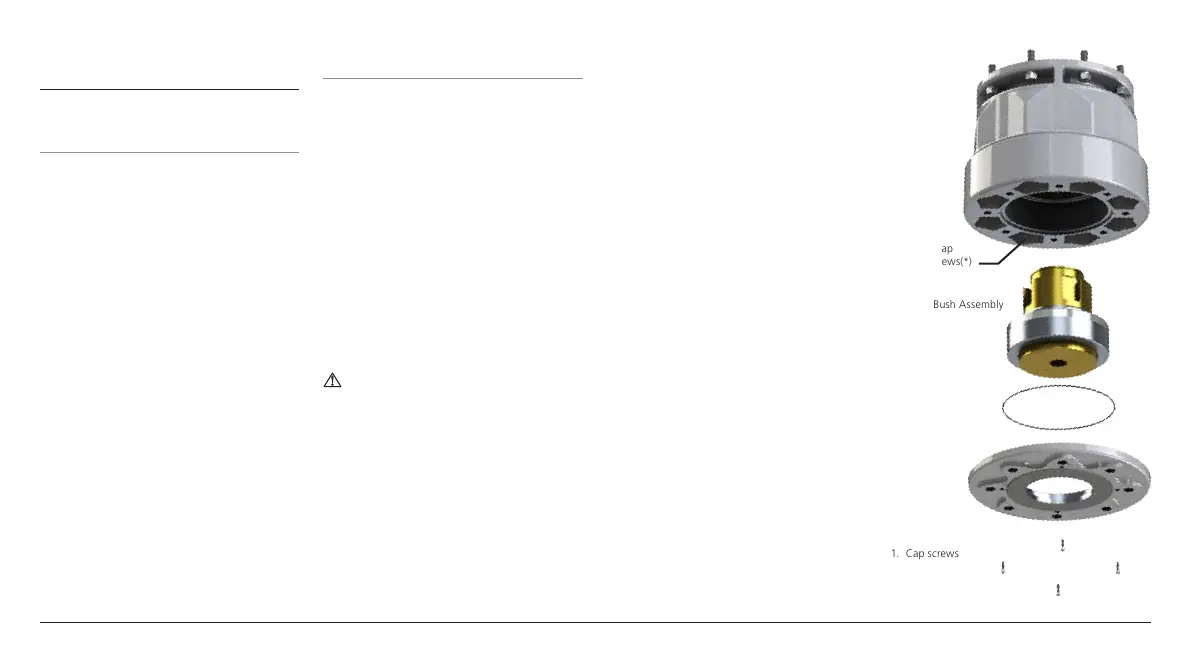

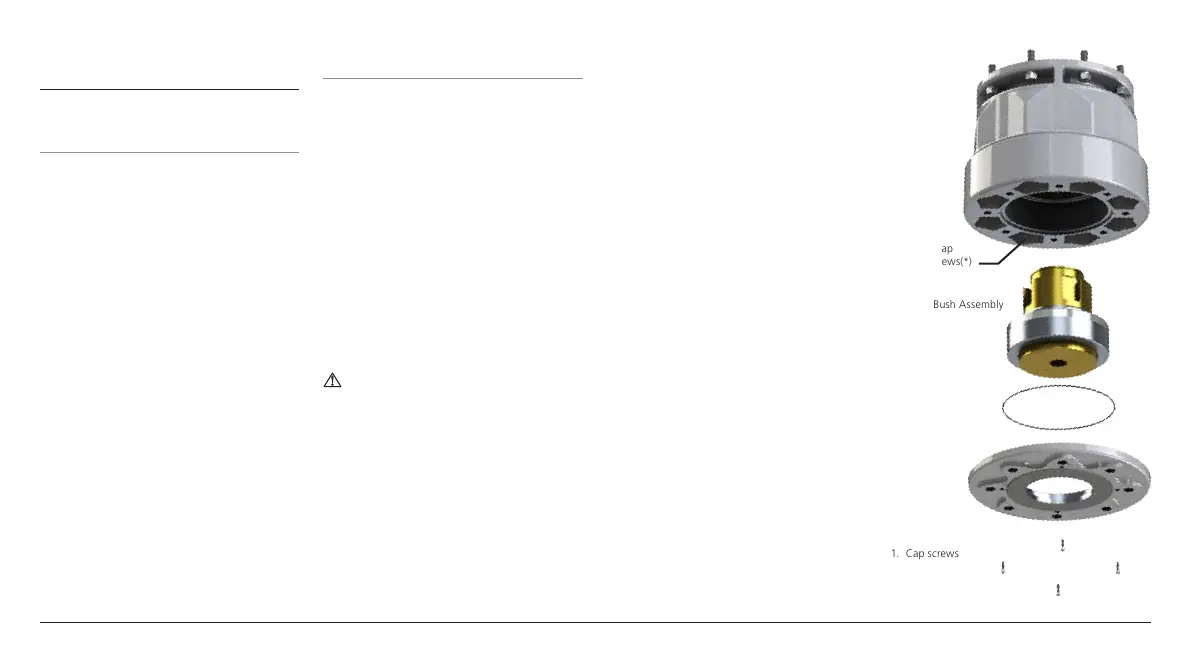

4.2 Fitting Thrust Compensator to

Valve Actuator: IQ40 – IQ95

Fit the loose base plate (2) and drive

bush assembly (3) on to the valve

stem. Lower the thrust compensator

housing onto the valve stem and drive

bush assembly (3). Rotate to align the

drive dogs of the hollow input shaft to

the slots on the machined drive bush

assembly (3). Lower until the thrust

compensator main body is positioned

onto the thrust compensator base

plate (2). Manually rotate the thrust

compensator assembly to align holes

in base plate (2) thrust compensator

housing and valve flange. Fit the

securing bolts and tighten to ensure

the thrust compensator is secure on

the valve flange.

WARNING: Remove lifting

equipment before commencing the

next step.

Fit the mounting studs to the actuator

until hand tight. Lower the actuator

onto the thrust compensator and

rotate until the mounting studs

are aligned with the holes on the

thrust compensator. Engage manual

operation, turn hand wheel until

the drive dogs on the actuator align

with the drive bush of the thrust

compensator. Lower the actuator until

the flange is flush with the thrust

compensator.

Using nuts provided, fix actuator to

thrust compensator and tighten to

required torque, 101 Nm / 74 lbf.ft.

Open the valve by 2 turns and firmly

tighten thrust compensator to the valve

flange. Fixings should be tightened as

per PUB002-039 Fig.6.1.3.

For all other Actuator mounting

instructions please refer to

PUB002-039.

Fig. 4.2.1

Thrust

Compensator

Housing

Recessed cap

headed screws(*)

1. Cap screws

3. Drive Bush Assembly

2. Base plate

Loading...

Loading...