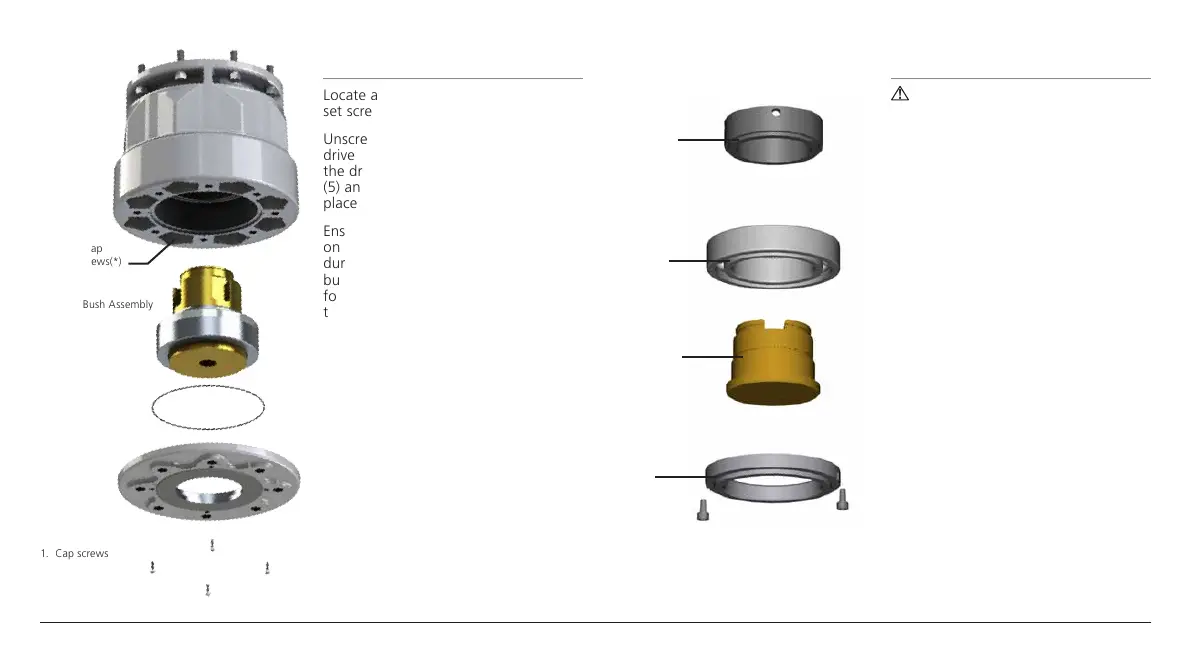

IQ3 manual – Section: Preparing the Drive Bush 3

Fig. 2.1.1

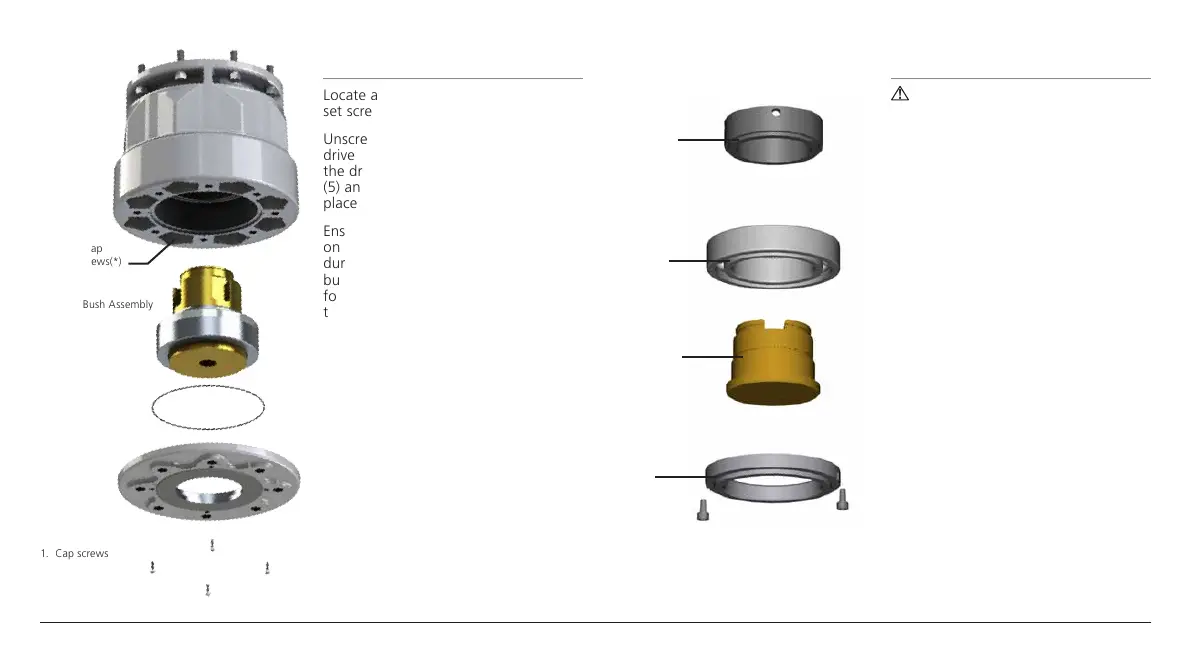

2.2 Disassembly of bearing

assembly: IQ10 – IQ35

Locate and loosen the locking socket

set screw in the bearing stop ring (7).

Unscrew the bearing stop ring from the

drive bush (5). Slide the bearing (6) off

the drive bush (5). Keep the drive bush

(5) and stop ring (7) in a safe clean

place.

Ensure the male thread and the O-ring

on the drive bush is not damaged

during machining. Machine the drive

bush (5) to suit the valve stem, allowing

for generous clearance on the screw

thread for rising stem valves.

Fig. 2.2.1

2.3 Reassembly:

IQ10 – IQ35

WARNING: Failure to fully clean

and grease the drive bush and

O-rings before reassembly could

result in damage.

Remove all swarf from the drive bush

(5) ensuring the O-rings on the drive

bush (5) and bearing stop ring (7) are

undamaged, clean and greased.

Slide the bearing assembly (6) onto the

drive bush (5) and ensure it is fitted

down to the drive bush shoulder.

Screw the bearing stop ring (7) with

the locking socket set screw uppermost

on to the drive bush (5) until it is hand

tight. Tighten the locking socket set

screw to lock rotation of the bearing

stop ring (7).

The locking socket set screw must

be sufficiently tight to prevent the

assembly working loose during

operation. Refer to the following table

for correct tightening information.

continued over...

Thrust

Compensator

Housing

Recessed cap

headed screws(*)

1. Cap screws

3. Drive Bush Assembly

2. Base plate

7. Bearing

Stop Ring

6. Sealed Thrust

Bearing

5. Drive Bush

4. Retaining

Plate

Loading...

Loading...