Operating Instructions

3-3

HP6A Manual

Limited Over Travel and Blind Holes:

A problem with stock removal with hone heads exists on many of today’s blocks and cylinders. It may be

necessary to relieve bores with a die grinder, portable grinder or boring bar.

Cross Hatch Angle:

Below is a formula used to determine what Strokes Per Minute and RPM to use to get a given cross hatch

angle. This formula is also available in Microsoft Excel format from Rottler Manufacturing via e-mail or

floppy disk. Several factors affect the crosshatch angle, below is a definition of these factors as they are

used in the formula.

RPM = Revolutions Per Minute the hone head is turning

L = Stroke Length. Actual length the hone head is moving up and down.

DIA = Bore Diameter

SPM = Strokes Per Minute of the Rocker Arm

A = Cross Hatch Angle

Mathematical Equation for SPM with given angle: (TAN(A/2))(*DIA*RPM)/(0.6366*L)

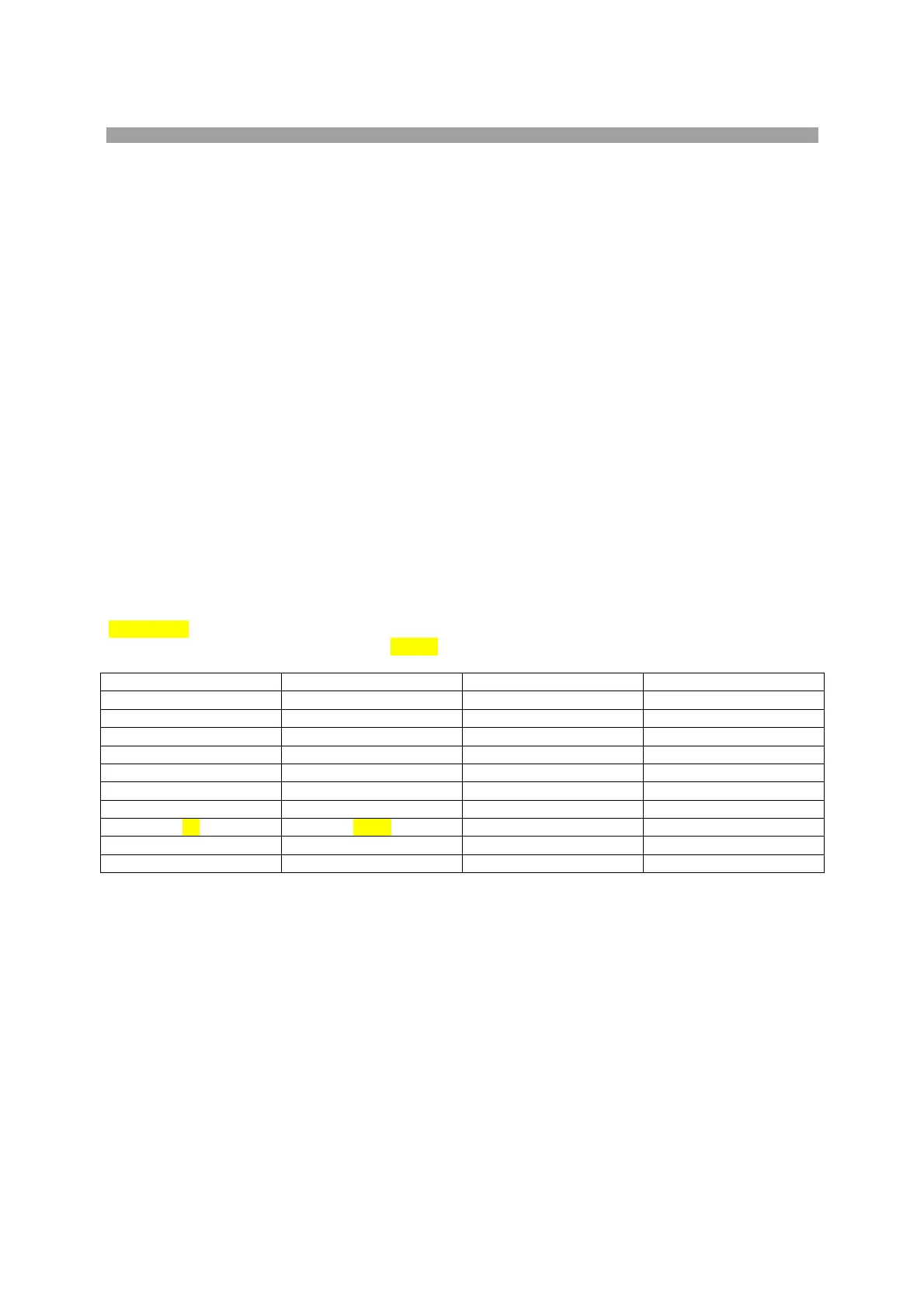

You will need a Scientific calculator to figure the TAN (tangent) or use the following table to get the

Tangent for a given angle.

Example:

A = 27 Degrees

DIA = 4.00

RPM = 195

L = 4.00

(TAN(27/2))(*4.00*195)/(0.6366*4.00) – Instead of doing the calculation in the shaded area use the table

to get the Tangent for that Angle as such: (.2400)(*4.00*195)/(0.6366*4.00)

ANGLE TANGENT ANGLE TANGENT

20 .1763 30 .2679

21 .1853 31 .2773

22 .1943 32 .2867

23 .2034 33 .2962

24 .2125 34 .3057

25 .2216 35 .3152

26 .2308 36 .3249

27 .2400 37 .3346

28 .2493 38 .3443

29 .2586 39 .3541

The remaining equation would be as follows:

Step 1, multiply first set: .2400 x 4.00 x 195 = 187.2

Step 2, multiply second set: 0.6366 x 4.00 = 2.5464

Step 3, divide Step 1 by Step 2 187.2 / 2.5464 = 73.5 or 74 Strokes Per Minute

Honing In General

The HP6A is capable of honing a cylinder very accurately with very little or no work from the operator.

The goal of the operator should be to set the Upper and Lower Stops correctly, select the proper stone

length, and honing pressure that will allow the machine to hone the cylinder to size.

While the HP6A is running, pay attention to the load display (upper left on the control panel). The load

display measures the actual motor load and displays it in percentage of rated motor current. As the

HP6A is honing, the control takes current measurements from the motor throughout the length of the

cylinder and displays them with the lights. The farther the lights move to the right the smaller the bore is

Loading...

Loading...