installing the unit _21

ENGLISH

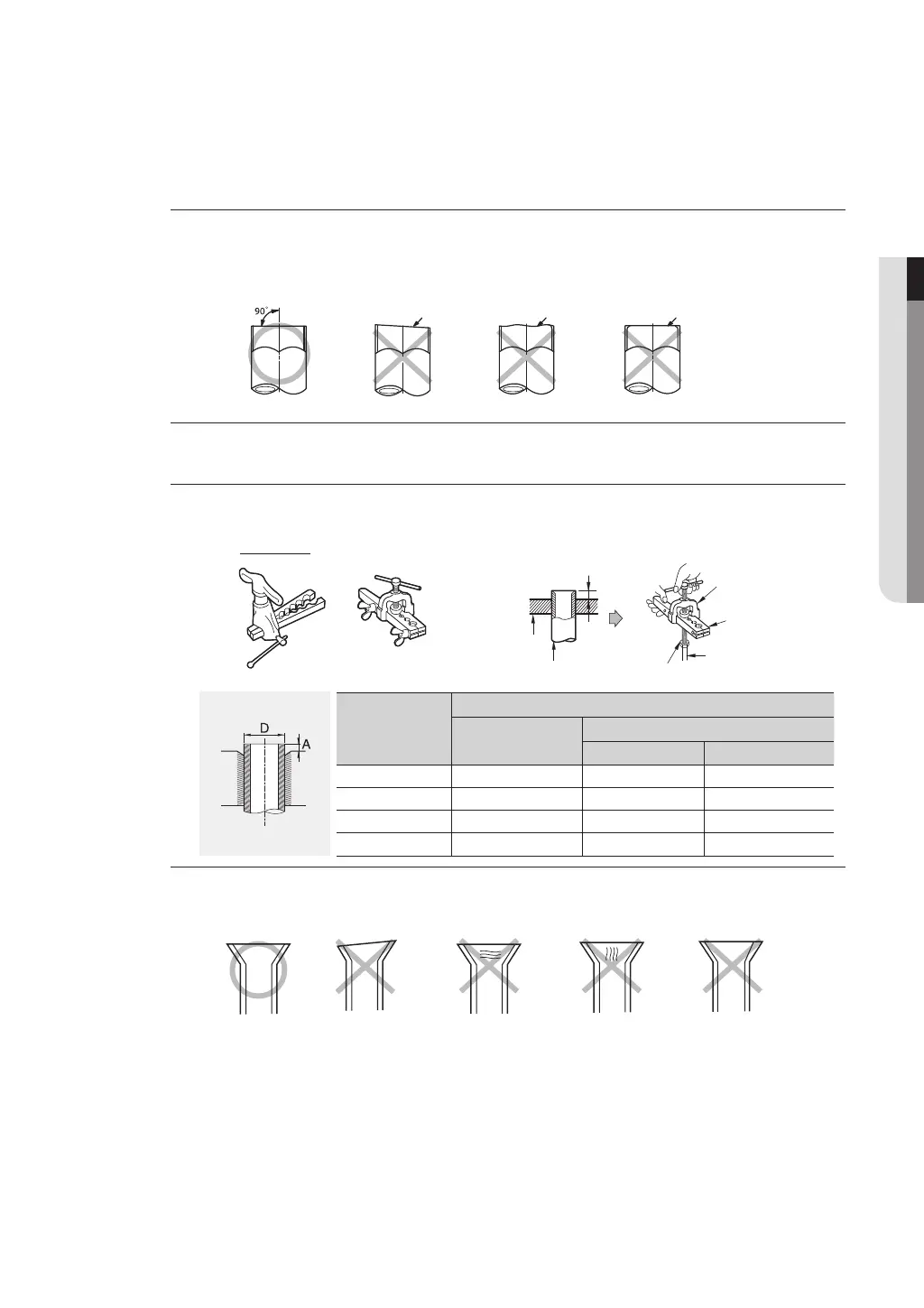

Cutting or Flaring the pipes

To prevent foreign materials or water from entering the pipe, it is important to keep the refrigerant pipe clean

and dry and to seal it while installing.

1. Make sure that you prepared the required tools.

(pipe cutter, reamer, flaring tool and pipe holder)

2. If you want to shorten the pipe, cut it using a pipe cutter ensuring that the cut edge remains

at 90° with the side of the pipe. There are some examples of correctly and incorrectly cut

edges below.

3. To prevent a gas leak, remove all burrs at the cut edge of the pipe using a reamer.

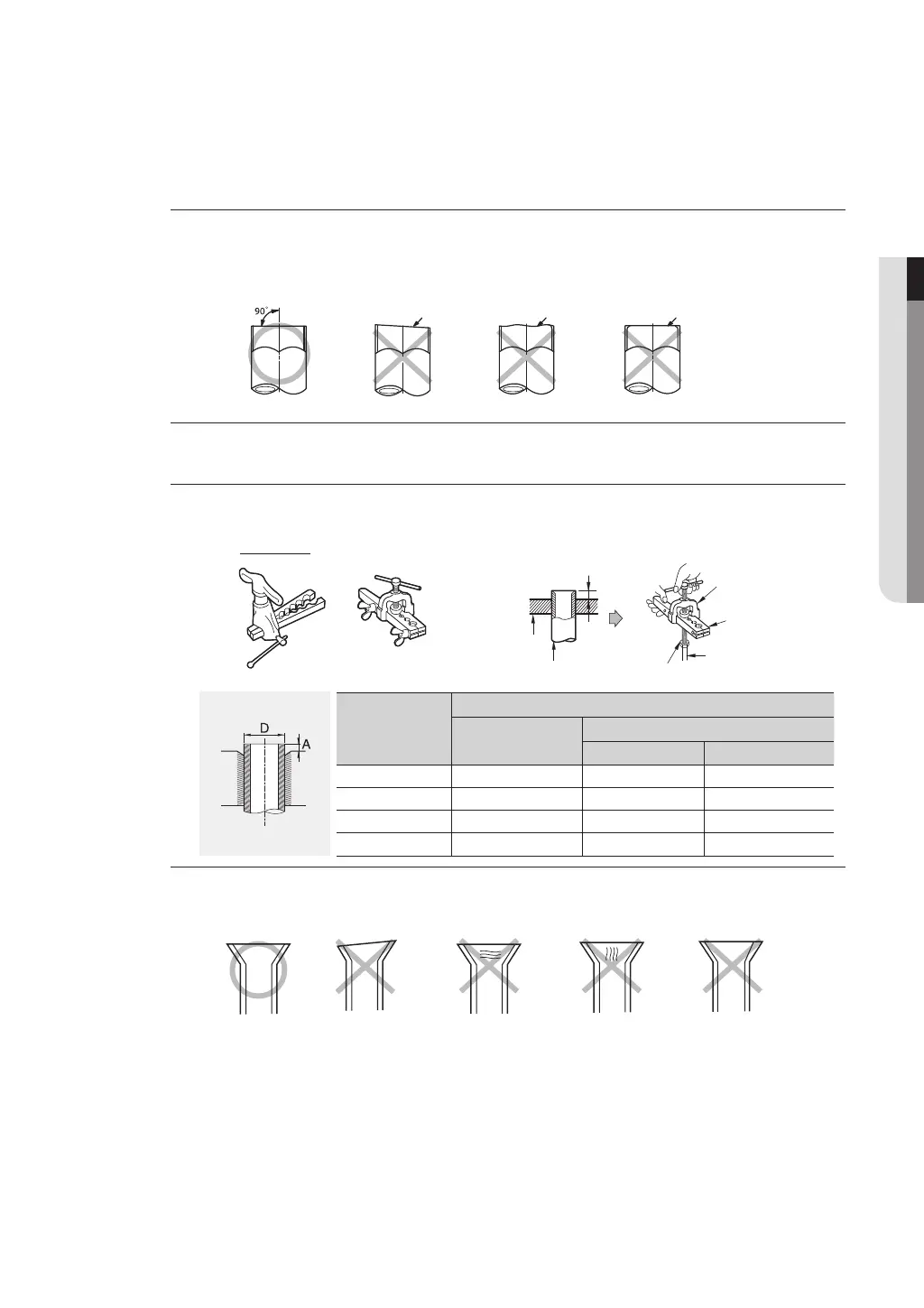

4. Carry out flaring work using flaring tool as shown below.

5. Check if you flared the pipe correctly. There are some examples of incorrectly flared pipes

below.

Oblique Rough Burr

A

Flaring bar

Copper pipe

York

Flaring bar

Copper pipe

Flare joint

Clutch type Wing nut type

Flaring tool

Outer diameter

[mm(inch)]

A[mm(inch)]

Flare tool for

R410A clutch type

Conventional flare tool

Clutch type Wing nut type

ø

6.35(

ø

1/4) 0~0.5(0~0.776)

1.0~1.5(0.039~0.059) 1.5 ~2.0(0.059~0.079)

ø

9.52(

ø

3/8) 0~0.5(0~0.776)

1.0~1.5(0.039~0.059) 1.5 ~2.0(0.059~0.079)

ø

12.70(

ø

1/2) 0~0.5(0~0.776)

1.0~1.5(0.039~0.059) 1.5 ~2.0(0.059~0.079)

ø

15.88(

ø

5/8) 0~0.5(0~0.776)

1.0~1.5(0.039~0.059) 1.5 ~2.0(0.059~0.079)

Inclined Damaged

surface

Cracked Uneven

thickness

DVM PLUS3_IM_E_31180-1.indd 21 2009-10-16 ソタネト 2:10:21

Loading...

Loading...