installing the unit

REFRIGERANT PIPING WORKS

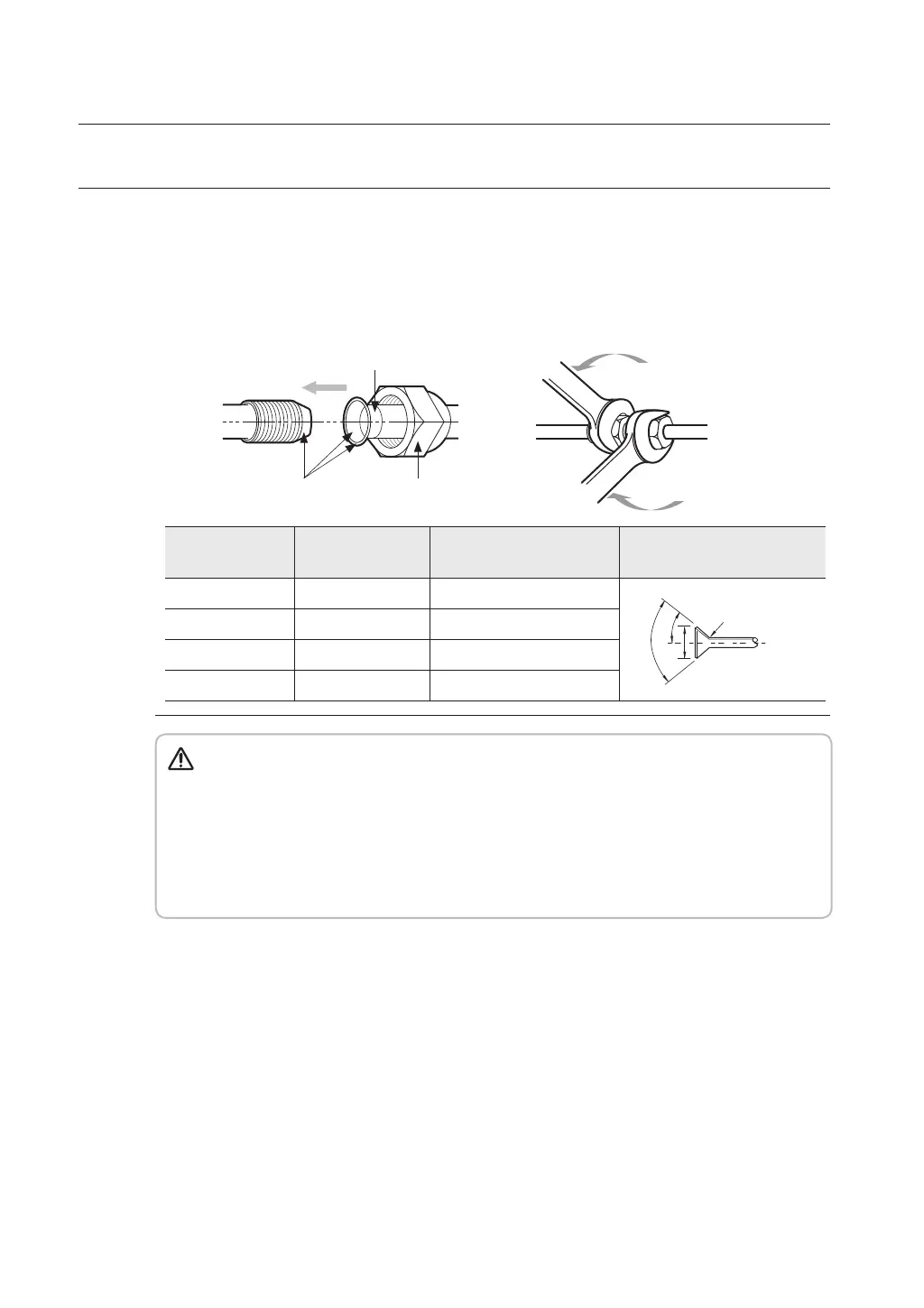

Aligning the pipes

• Check that the flaring is properly made.

• Align the center of the piping and sufficiently tighten the flare nut with fingers. Finally, tighten

the flare nut with torque wrench until the wrench clicks. When tightening the flare nut with

torque wrench, ensure the direction for tightening follows the arrow on the wrench.

• Make sure to use ester oil to coat the flare connection section.

Pipe

Flare jointFlare connection section

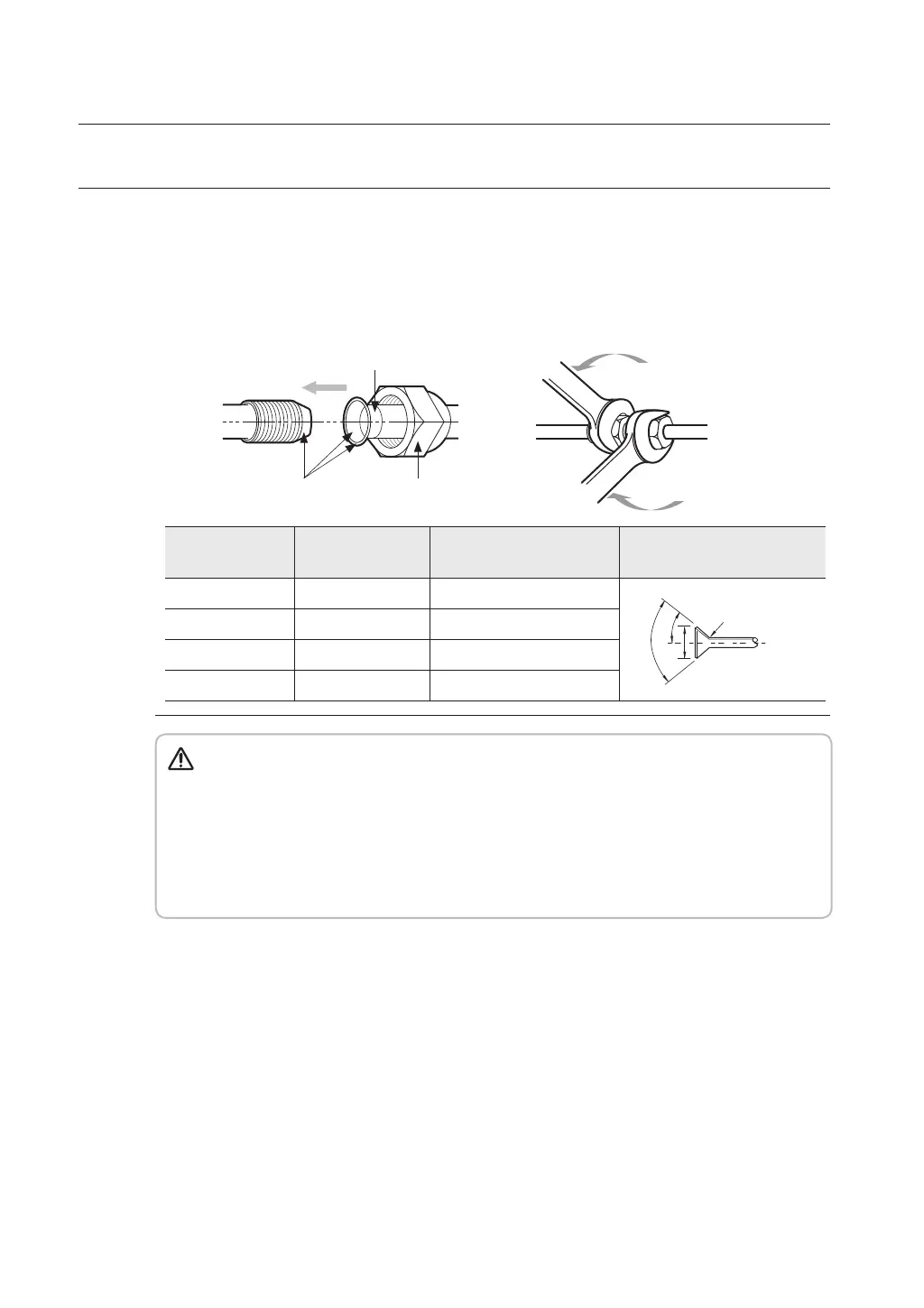

Outer diameter

[mm(inch)]

Connection

torque (kgf•cm)

Flare dimension

[mm(inches)]

Flare shape [mm(inches)]

ø

6.35(

ø

1/4) 145~175 8.70~9.10(0.343~0.358)

ø

9.52(

ø

3/8) 333~407 12.80~ 13.20(0.504~0.520)

ø

12.70(

ø

1/2) 505~615 16.20~ 16.60(0.638~0.654)

ø

15.88(

ø

5/8) 630~769 19.30~ 19.70(0.760~0.776)

R 0.4~0.8(0.0157~0.0314)

90° ±2°

45°

±2°

Caution for connecting the pipe

• Blowing Nitrogen gas should be done when brazing the pipe.

• Make sure to use the provided flare joint.

• Make sure that there are any cracks on the bent pipe.

• Do not fasten the flare joint with excessive strength.

• Use ester oil to coat the flare connection section to prevent refrigerant leak.

R410A is a high pressure refrigerant therefore there is a risk of refrigerant leakage

if the flare connection is not coated by ester oil.

CAUTION

DVM PLUS3_IM_E_31180-1.indd 22 2009-10-16 ソタネト 2:10:22

Loading...

Loading...