SQmin Function

Purpose To display the allowable minimum sample quantity “SQmin” (sample quantity

minimum) in accordance with the United States Pharmacopoeia (USP). According to

USP guidelines, the uncertainty of measurement may not exceed 0.1% of the sample

quantity when substances are weighed with the highest degree of accuracy for

volume determination. This additional function ensures that weighing results lie

within defined tolerance limits corresponding to the requirements of your quality

assurance system.

System Requirements The scale must be set up by a service technician to be able to use the SQmin

function. The technician will determine the permitted minimum sample quantity

and load this to your scale using the guidelines of your QA system. He will document

this setting via a “Weighing module test as per USP" certificate in which the

measurements and min. sample quantity are logged. The SQmin function ensures

that the weighing results correspond to USP guidelines. These SQmin settings

cannot be changed by the user.

Features – Displaying the minimum sample quality: The value is displayed in the text line

for 4 seconds after pressing the k key.

– If the minimum sample quantity has not been reached: The k symbol is

displayed and weight values are marked with a “!" in the printout.

– GLP header: The minimum sample quantity entered for SQmin can be included

on the printout.

Setting SQmin parameters

The SQmin display must be turned on to use the SQmin function.

Menu: SETUP / SQMIN /

SQmin display: DISPLAY yes/no*

Print in GLP header: GMP PRT. yes/no*

* = Factory setting

Operating Instructions Combics Indicators 49

Operation

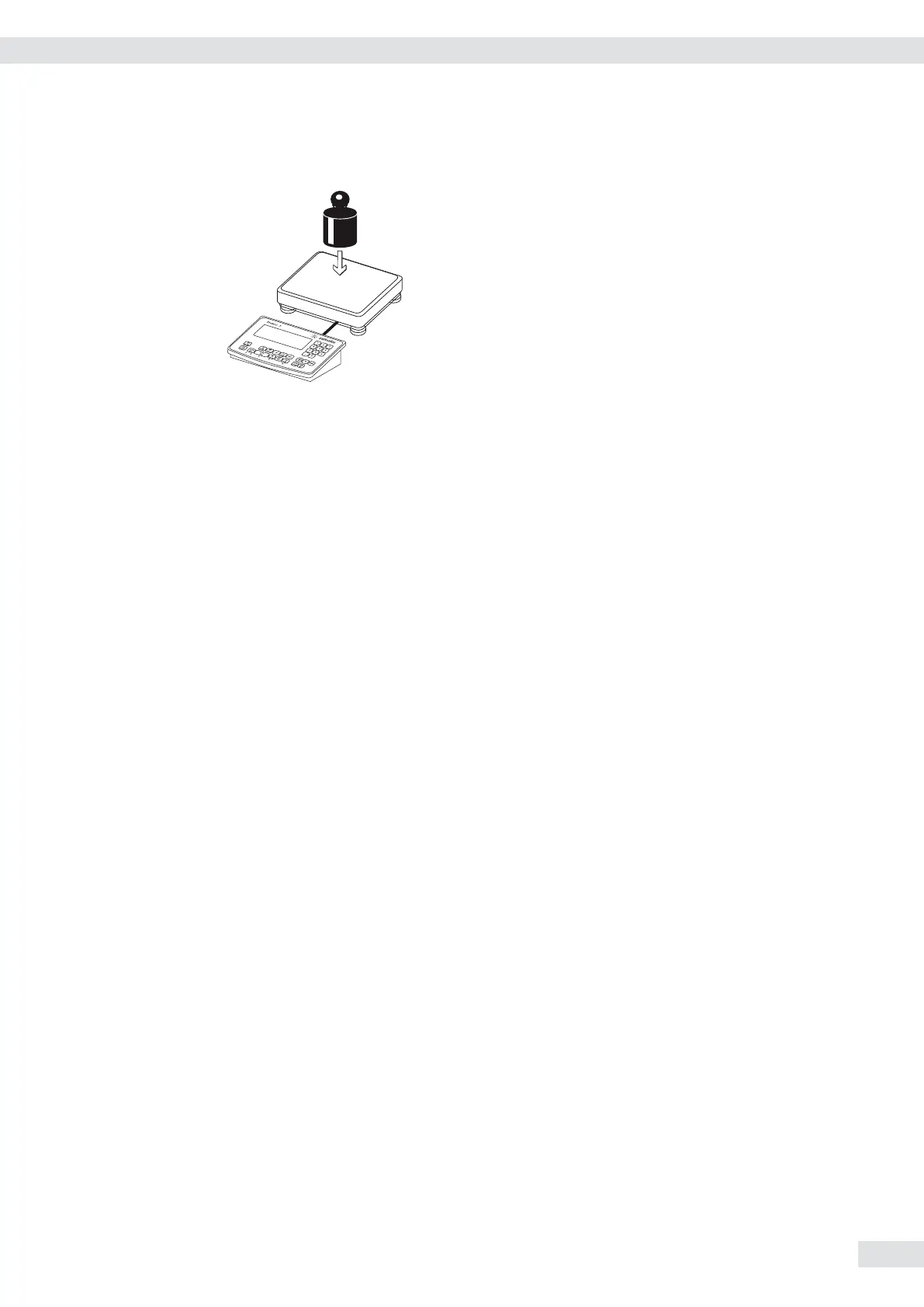

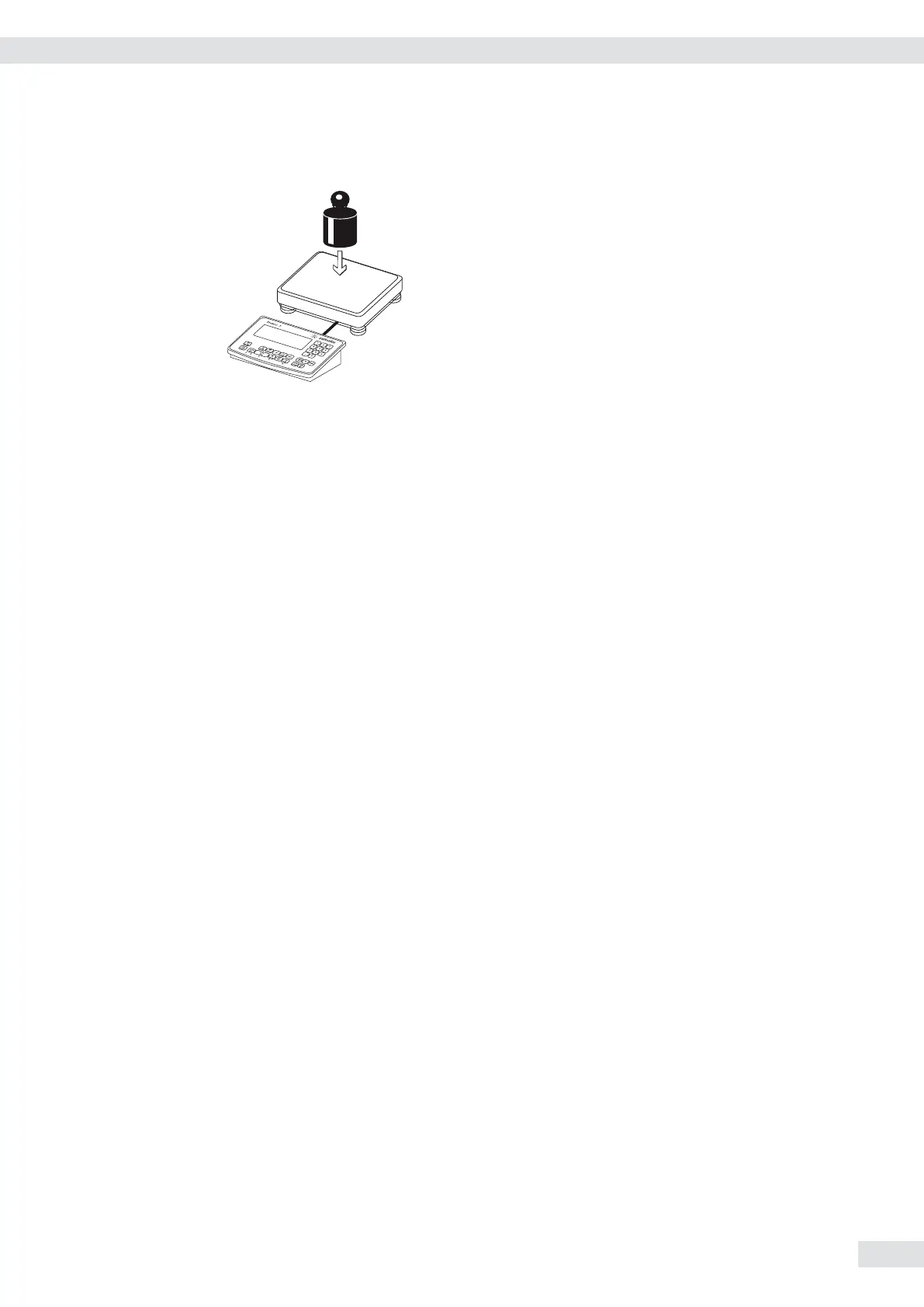

4.) Place the calibration/adjustment weight

on the weighing platform. The adjust-

ment weight is displayed once the adjust-

ment is finished. Remove the adjustment

weight from the weighing platform.

Loading...

Loading...