Operation

CAUTION!

Risk of machine

damage!

BA SCV_EN

V06 | 11.2015

www.schaerer.com

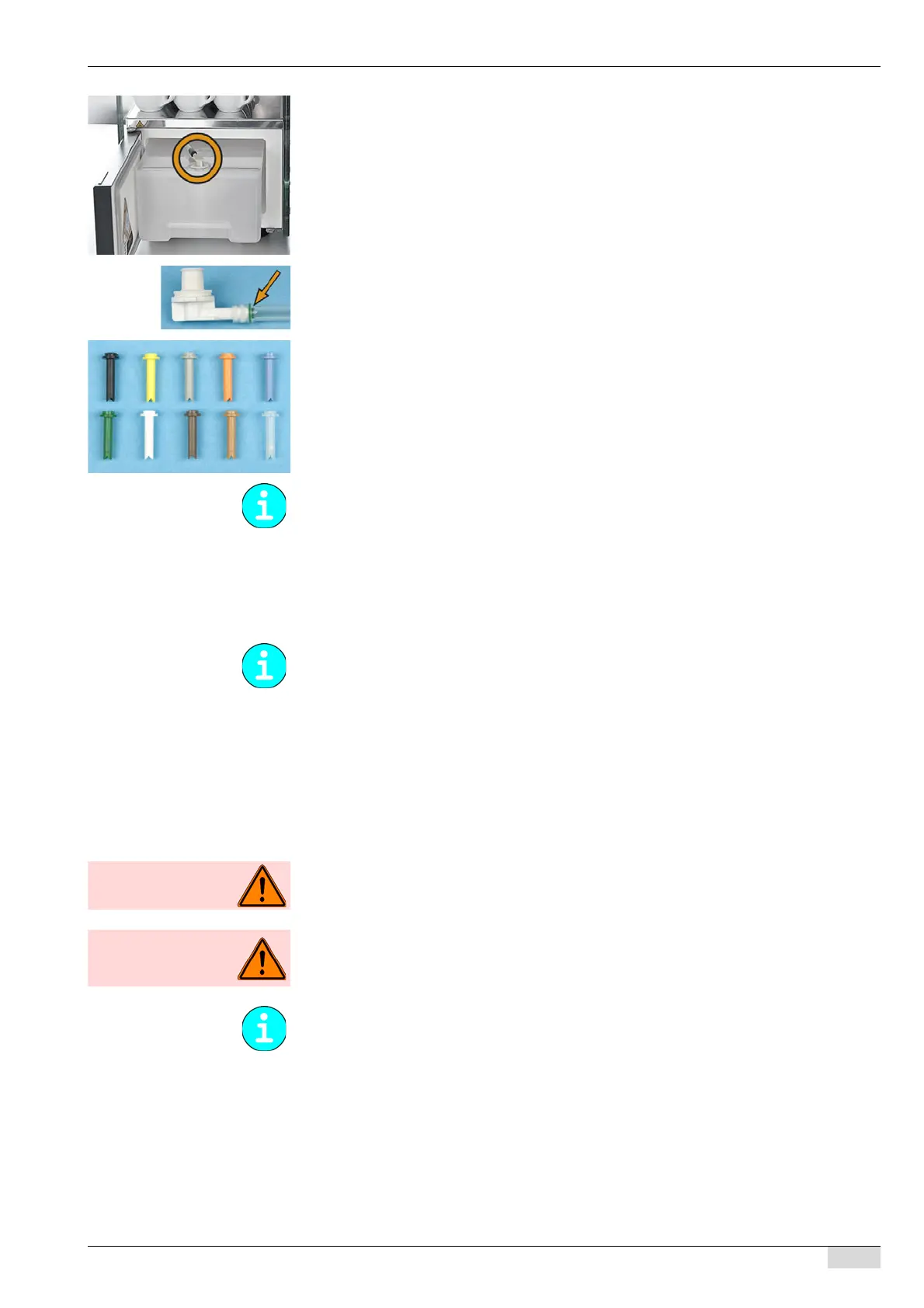

► Open the door.

► Pull the milk hose adapter out of the lid.

► Connect the desired milk nozzle (1 mm – 1.7 mm) between the hose and the adapter if not

already installed.

► Remove and rinse the milk container.

► Pour in fresh, pre-cooled milk (3 – 5°C).

► Place the milk container back in the cooling unit.

► Push the hose adapter back into the lid.

► Close the door.

The milk nozzles (1 mm – 1.7 mm) contained in the scope of delivery influence the milk tem-

perature. If the milk foam is too cold, a smaller nozzle diameter is necessary. If the milk foam

is too hot, a larger nozzle diameter is necessary.

Option: Under-machine cooling unit

► Open the door.

► Remove and rinse the milk container.

► Pour in fresh, pre-cooled milk (3 – 5°C).

Ensure that the filled milk does not touch the closed milk container lid.

► Place the milk container into the cooling unit.

► Place the hose in the container.

The hose end must be in contact with the container floor.

► Close the door.

Automatic machine powder

Danger of injury from rotating dosing screws!

Never reach into the powder container while the device is switched on.

Risk of blockage from adding improper powder!

Never fill anything into the powder container other than powder for automatic opera-

tion.

Ensure that the filled choco powder does not touch the closed powder container lid.

Option 1: Choco

► Add the desired choco powder.

Option 2: Topping

► Add the desired milk powder.

31

Loading...

Loading...