Troubleshooting www.schaerer.com

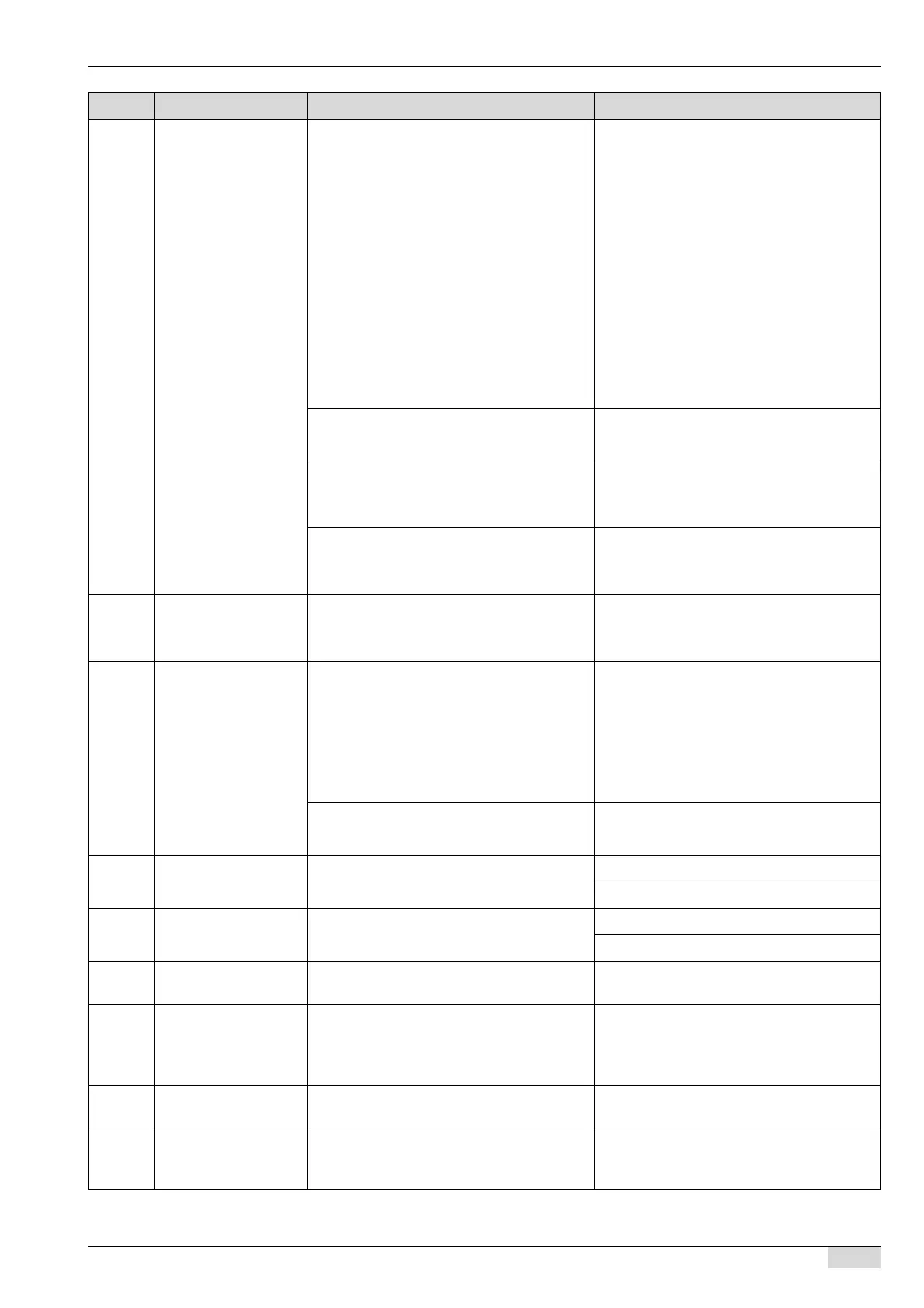

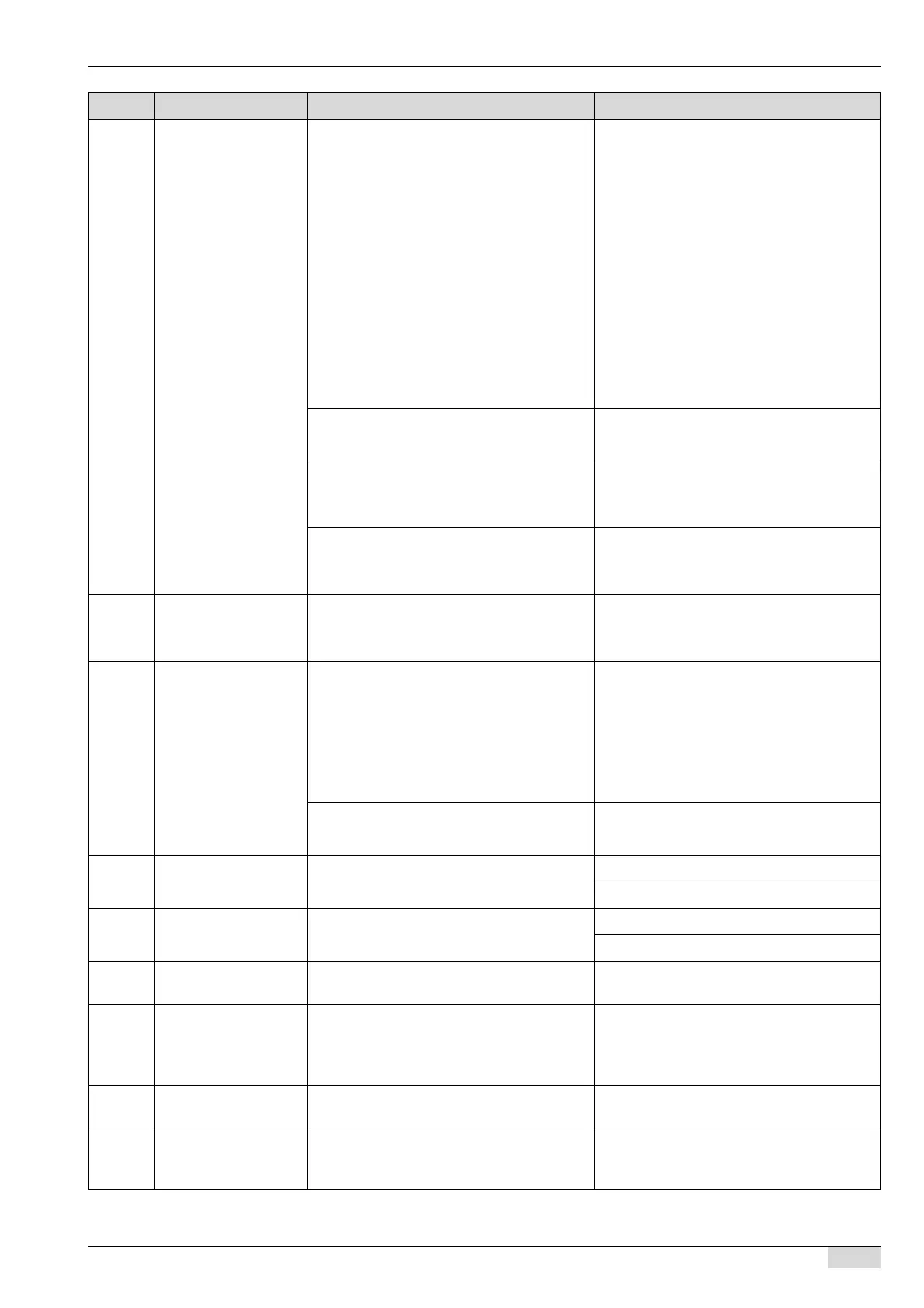

Code Designation Cause and effect What to do

161 Brew water fault The water supply is interrupted.

Dispensing of beverages is blocked.

Option 1: With drinking water tank

► Check that the drinking water tank is filled

and installed correctly.

Option 2: With mains water supply

► Check whether the main water valve is

open.

Option 3: Aquaflex

► Check whether the switch between the

mains water supply and drinking water

tank is correctly set.

See "Installation and commissioning" -

"Switching between mains water supply and

drinking water tank"

The brewing unit is blocked.

Dispensing of beverages is blocked.

► Clean the brewing unit.

See "Cleaning" - "Weekly cleaning".

The grind level setting is too fine.

The fine dust contaminates the mill too quick-

ly.

► Set the grind level one level coarser.

See "Service and maintenance" - "Finer set-

ting of grind level".

The highest quality level can lead to a brew-

ing water error.

► Set the quality lower.

See "Programming" - "Settings" menu -

"Recipes and beverage buttons".

162 Flow meter error du-

ring cleaning

• Water pressure is OK.

• Minimum flow not achieved.

• A mandatory cleaning routine follows.

► Check the water supply.

163 Warm rinse water fault The water supply is interrupted.

Dispensing of beverages is blocked.

Option 1: With drinking water tank

► Check that the drinking water tank is filled

and installed correctly.

Option 2: With mains water supply

► Check whether the main water valve is

open.

The brewing unit is blocked.

Dispensing of beverages is blocked.

► Clean the brewing unit.

See "Cleaning" - "Weekly cleaning".

164 Flow meter error du-

ring hot water dosing

Minimum flow not achieved. ► Check the water supply.

► Check and clean the brewing unit.

165 Flow meter error du-

ring choco dosing

Minimum flow not achieved. ► Check the water supply.

► Check and clean the powder doser.

166 Flow meter error du-

ring steam boiler feed

Minimum flow not achieved. ► Check the water supply.

167 Flow meter error du-

ring descaling

• Minimum flow not achieved.

• During descaling, the screw in the drink-

ing water tank neck must be removed on

machines with a mains water supply.

► For descaling, remove the screw from the

drinking water tank neck (reinsert after

descaling).

170 Steamer sensor short

circuit

Infinite resistance at control input for sensor. ► Contact your service partner.

171 Steamer sensor bro-

ken/not correctly

mounted

Resistance at control input for sensor ap-

proaches zero.

► Contact your service partner.

BA SCV_EN

V06 | 11.2015

89

Loading...

Loading...