www.scheppach.com

48

|

GB

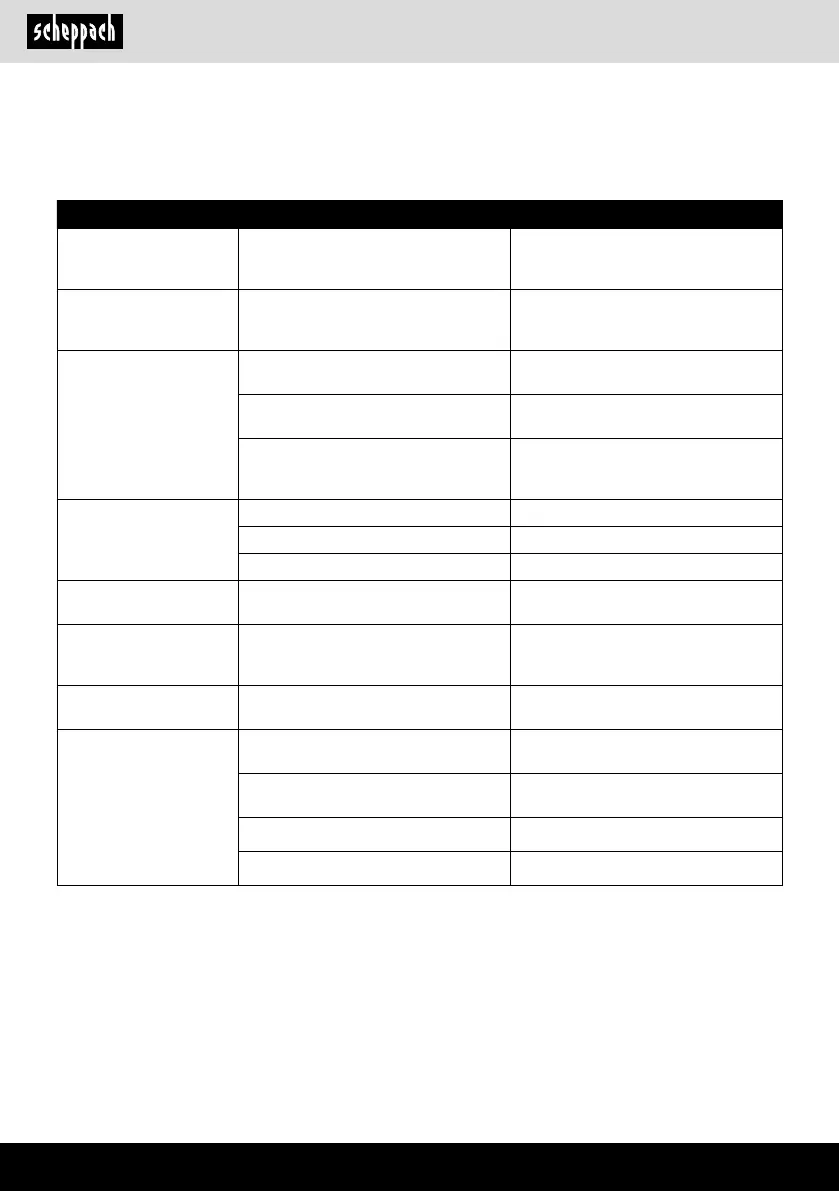

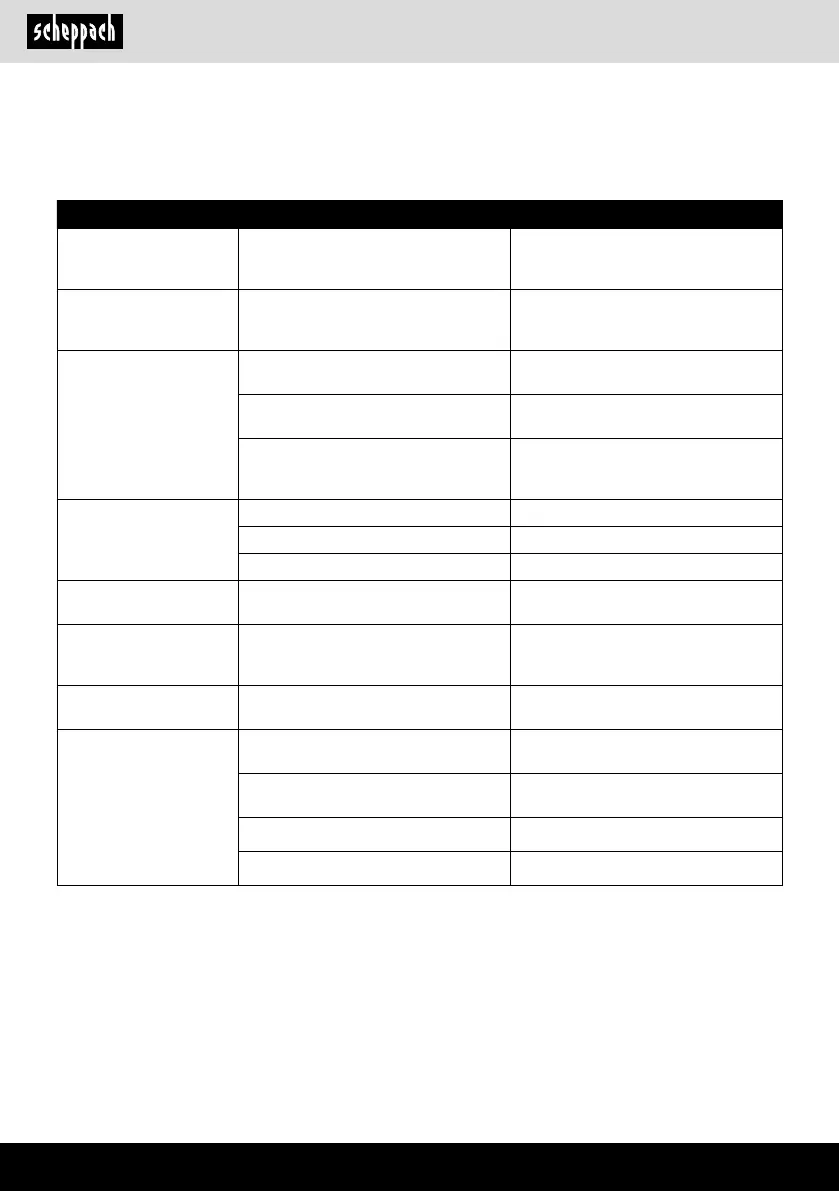

17. Troubleshooting

The following table shows fault symptoms and describes remedial measures in the event of your machine failing to

work properly. If you cannot localise and rectify the problem with this, please contact your service workshop.

Fault Possible cause Remedy

Motor (18) is running, split-

ting column (1) does not

move up.

Motor (18) turns in the wrong direction. Turn the phase inverter in the power con-

nection (see point 10.6).

The motor (18) ends the

splitting process automat-

ically.

Overvoltage protective device was trig-

gered.

Call a qualied electrician.

The splitting column (1)

only moves down slowly.

Not enough oil available. Check oil level with oil dipstick (24)

screwed in.

Bleed screw (23) is closed. Loosen the bleed screw (23) two turns

before use.

Check if the cap nut (stroke setting bar)

(26) of the stroke setting bar (15) is loose.

Tighten the cap nut (stroke setting bar)

(26) of the stroke setting bar (15). If nec-

essary, t a new cap nut.

Log is not split.

Log splitter loaded incorrectly. Insert the log correctly.

Splitting wedge (2) is blunt. Grind the splitting wedge (2).

Oil leaks. Locate the leak, contact the dealer.

Splitting column (1) vi-

brates, makes noise.

Low oil and excess air in the hydraulic

system.

Check the oil level, top up if necessary,

otherwise contact the dealer.

Splitting column (1) vi-

brates strongly in the up-

per position.

Plastic guides are worn out. Replace the plastic guides at the top and

bottom.

Hydraulic pump whistles.

Too little hydraulic oil in the hydraulic oil

tank (6).

Top up hydraulic oil.

Oil leakage at splitting col-

umn (1)

or in other places.

Trapped air in the hydraulic system during

operation.

Loosen the bleed screw (23) two turns

before use.

Bleed screw (23) not tightened before

transport.

Tighten bleed screw (23) before trans-

port.

Oil drain screw (25) loose. Tighten the oil drain screw (25) rmly.

Oil valve and/or seals defective. Contact dealer.

Loading...

Loading...