Operating Manual Linear ACTUSAFE CMFS(L)

OM-ENGLISH-Failsafe-Linear-16xx-V2.00-2022.03.03 5 Transport and Storage

4.5 Protective devices

See Operating Manual ACTUSMART CM.V1.2, section 2.7, page 25

4.6 Ambient temperature

See Operating Manual ACTUSMART CM.V1.2, section 2.8, page 25

4.7 Condition on delivery of the actuators

See Operating Manual ACTUSMART CM.V1.2, section 2.9, page 25

4.8 Note (tag)

See Operating Manual ACTUSMART CM.V1.2, section 2.10, page 25

5 Transport and Storage

See Operating Manual ACTUSMART CM.V1.2, section 3, page 26

6 Installation Instructions

Installation work of any kind for the actuator may only be performed by qualified personnel.

6.1 Mechanical connection; preparations:

Check,

• whether valve flange and actuator base match

• if the bore of the coupling piece coincides with the spindle pin and sufficient thread engagement is available

NOTE: Make sure that both the valve and the actuator are in the failsafe position.

General procedure:

• Clean the bare parts on the actuator coated with rust protectant.

• Clean the mounting surface for the fitting thoroughly.

• Lightly grease the valve stem.

• Put the actuator on the valve.

• Pay attention to the centered position and full support surface of the flanges.

• Fasten the actuator with suitable bolts:

– Minimum strength grade: 8.8 or A2-70

– Ensure sufficient thread engagement (min. 1xd)

CAUTION: Screws that are too long may go against the thread root, creating the risk of the actuator moving

radially vis-à-vis the fitting. This may lead to the bolts shearing off.

NOTE: Unsuitable bolts may result in the actuator falling off!

• Tighten bolts to the correct torque, alternating between bolts on opposite sides

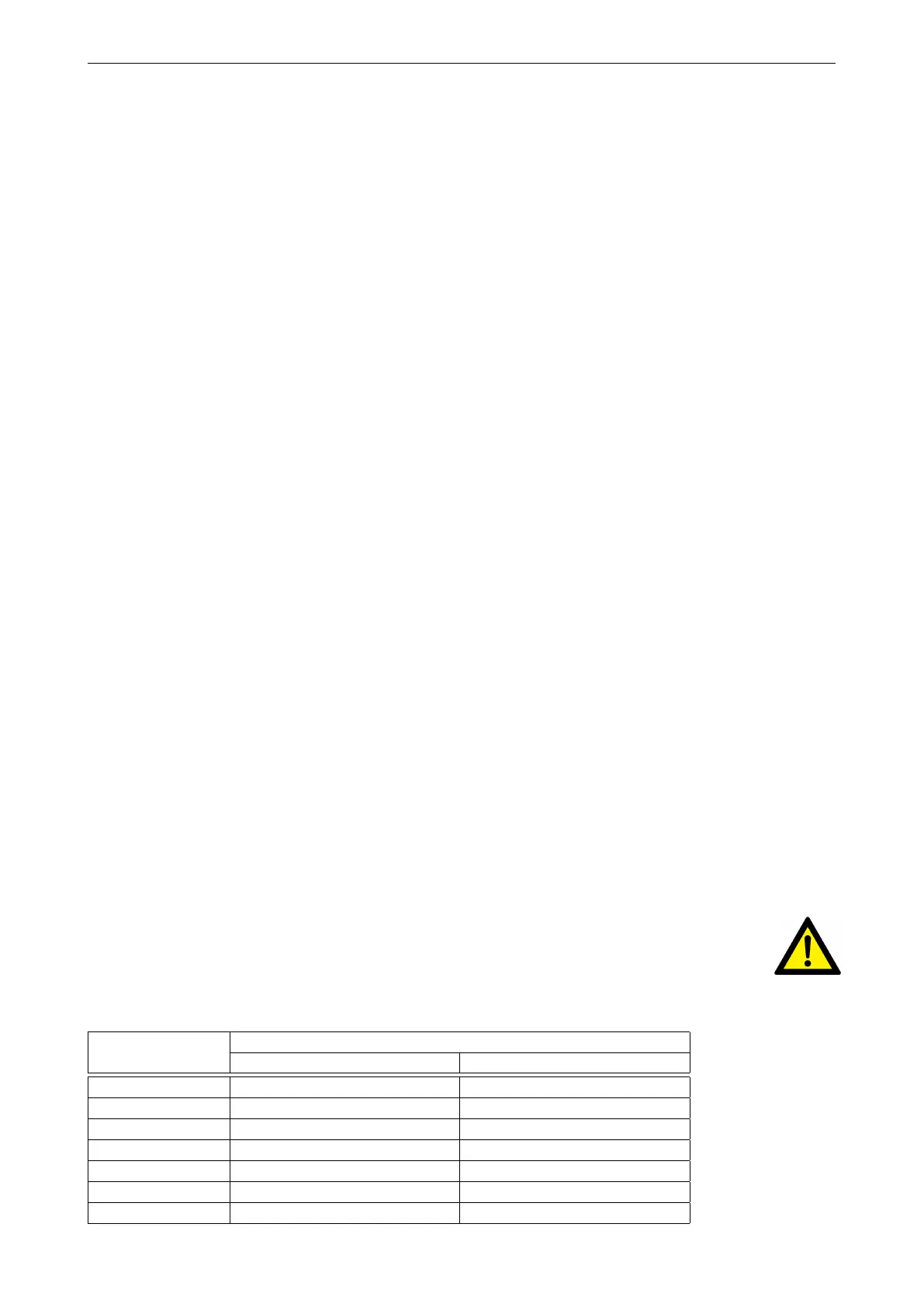

Thread Tightening torque [Nm] for bolts with strength grade

8.8 A2-70 / A4-70

M6 11 8

M8 25 18

M10 51 36

M12 87 61

M16 214 150

M20 431 294

M30 1489 564

9

Loading...

Loading...