10 Quality monitoring

SCHMIDT

®

PressControl 3000 – V1.3

45

Zoom All

Zoom Fit

Zoom -

Record reference data

The recorded curves, together with their respective tolerance limits, are

displayed in the curve output over the entire force and stroke range.

The recorded curves, together with their respective tolerance limits, are

displayed in the curve output in the adapted form.

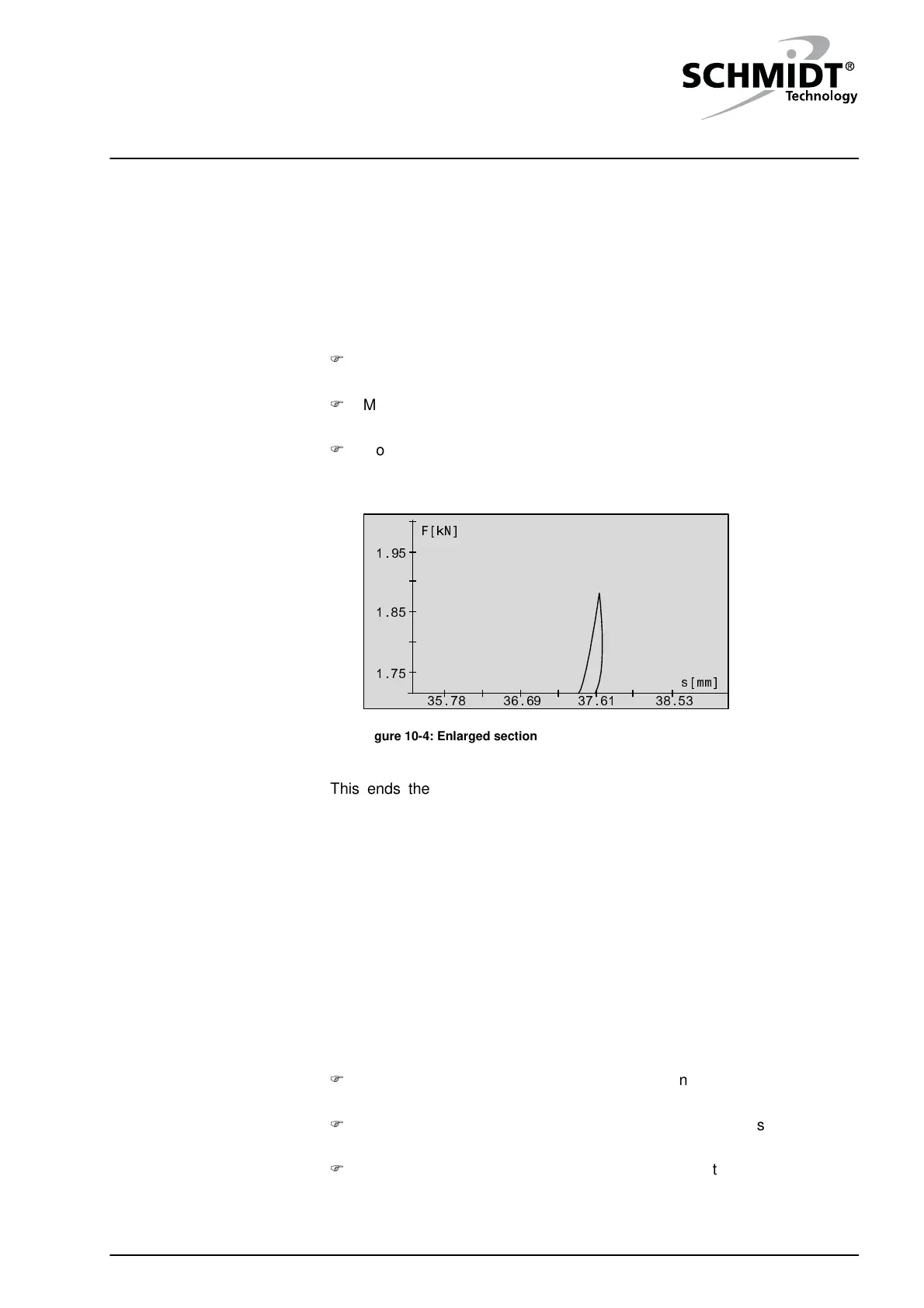

To enlarge a certain area:

Select the "Zoom +" command. The display switches to curve output

and a cursor appears additionally.

Move the cursor using the cursor keys to the left, upper corner of the

desired detail and confirm the position with the "Enter" key.

Move the cursor using the cursor keys to the right, lower corner of the

desired detail and confirm the position with the "Enter" key. The

selected detail shown enlarged.

1.95

1.85

1.75

F[kN]

s[mm]

35.78 36.69 37.61 38.53

Figure 10-4: Enlarged section

This ends the enlarged display. The display goes back to the last curve

display.

10.2 Tolerances

Reference data

With the help of the reference data, the quality features can be defined for

individual workpieces.

To be able to define the quality requirements for the individual workpieces,

you first have to record the reference data.

Set the "Output Diagram" parameter to "Continuous" to display all force

curves as a group of curves.

Produce a workpiece and check whether it meets the quality

requirements.

Repeat the production process and the check until a Not O.K. part is

produced. When compared to the recorded curves, this Not O.K. part

exhibits an outlier in at least one place.

Zoom +

Loading...

Loading...