POST-OPERATION CARE

WARNING

Allow engine to cool before per-

forming any maintenance.

General Care

Take the watercraft out of the water

every day to prevent marine organism

growth.

Should any water be present in the

bilge, install safety lanyard on its post

to start the electric bilge pump. If

some water remains, unscrew the

drain plugs and tilt the watercraft rear-

ward in order to allow water to flow

out.

Wipe off any remaining fluid in the en-

gine compartment (bilge, engine, bat-

tery, etc.) with clean dry rags (this is

particularly important in salt water op-

eration).

Additional Care for Foul

WaterorSaltWater

When the watercraft is operated in

foul water and particularly in salt wa-

ter, additional care should be taken

to protect the watercraft and its com-

ponents. Rinse off trailer and water-

craft's bilge area with fresh water.

CAUTION: Failure to perform

proper care such as: watercraft

rinsing, cooling system flushing or

anticorrosion treatment, when wa-

tercraft is used in salt water, will

result in damage to the watercraft

and its components. Never leave

the watercraft stowed in direct sun-

light.

Cooling System Flushing

and Engine Internal

Lubrication

General

Flushing the cooling system with fresh

water is essential to neutralize cor-

roding effects of salt or other chemi-

cal products present in water. It will

help to remove sand, salt, shells or

other particles in water jackets (en-

gine, exhaust manifold, tuned pipe)

and/or hoses.

Engine lubrication and flushing should

be performed when the watercraft is

not expected to be used further the

same day or when the watercraft is

stowed for any extended time.

WARNING

Perform this operation in a well

ventilated area.

Proceed as follows:

Clean jet pump by spraying water in its

inlet and outlet and then apply a coat-

ing of BOMBARDIER* LUBE lubricant

or equivalent.

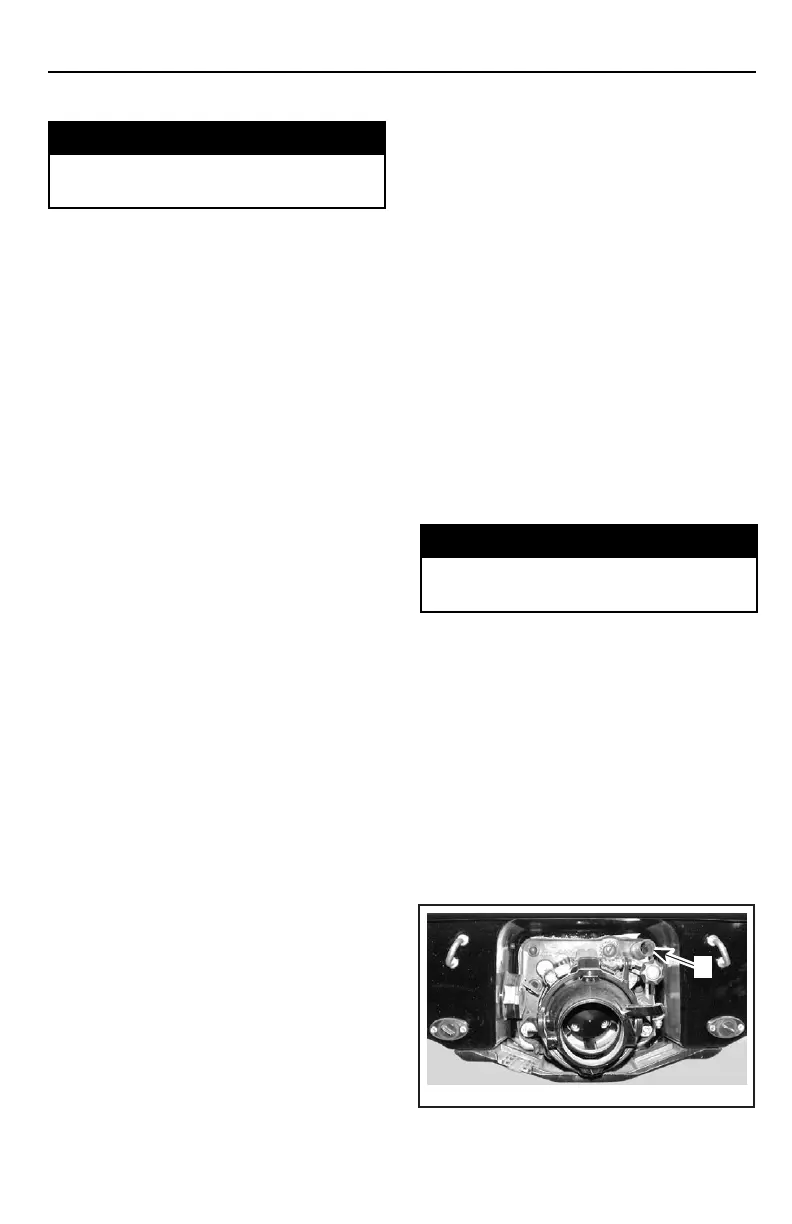

Connect a garden hose to the fitting

located at the rear of watercraft on jet

pump support.

NOTE: If desired, a quick connect

adapter can be used (P/N 295 500

473). No hose pincher is required to

flush engine.

F22J01Y

1

1. Flushing connector

_____________________

63

Loading...

Loading...