49

CAPACITOR TYPES

There are many different types of capacitors, using

different types of dielectrics, each with its own best

capability. When replacing capacitors, it is best to

replace with a capacitor having not only the same

capacity and tolerance, but the same type of dielectric

and temperature characteristics as well. This will insure

continued performance equal to the original.

The capacitor is often named according to the type of

dielectric which is used, such as paper, mylar, ceramic,

mica or aluminum electrolytic.

Paper and mica were the standard dielectric materials

used in capacitors for years. Ceramic became popular

due to its stability and controlled characteristics and

lower cost over mica. Today, there are many dielectrics

with different ratings and uses in capacitors. Plastic

films of polyester, polycarbonate, polystyrene,

polypropylene, and polysulfone are used in many of the

newer large value, small size capacitors. Each film has

its own special characteristics and is chosen to be used in

the circuit for this special feature. Some of the plastic

films are also metalized by vacuum plating the film with

a metal. These are generally called self-healing type

capacitors and should not be replaced with any other

type.

Aluminum Electrolytics

The aluminum electrolytic capacitor or “Lytic” is a very

popular component. Large value capacity in a relatively

small case with a fairly high voltage rating can be

obtained quite easily. The aluminum lytic is used in

power supply filtering, audio and video coupling and in

bypass applications.

The aluminum lytic is made by using a pure aluminum

foil wound with a paper soaked in a liquid electrolyte.

When a voltage is applied to the combination, a thin

layer of oxide film forms on the pure aluminum forming

the dielectric. As long as the electrolyte remains liquid,

the capacitor is good or can be reformed after sitting for

a while. When the electrolyte dries out, the leakage goes

up and the capacitor loses capacity. This can happen to

aluminum lytics just sitting on the shelf. When an

aluminum lytic starts drying out, the capacitor begins to

show dielectric absorption. Excessive ESR is also a

common failure condition for aluminum lytic capacitors.

Tantalum Electrolytics

The tantalum electrolytic capacitor is also quite popular.

While the leakage in the aluminum lytic is very high due

to the nature of its construction, leakage in tantalum

capacitors is very low. In addition, tantalum capacitors

can be constructed with much tighter tolerances than the

aluminum lytic. The tantalum is much smaller in size for

the same capacity and working voltage than an

aluminum lytic. Tantalum lytics are popular in circuits

where high capacity and low leakage is required. The

capacity and voltage rating of the tantalum lytic is

limited, and for extremely large values of capacity and

higher voltages in power supply filtering, the aluminum

lytic is still the first choice.

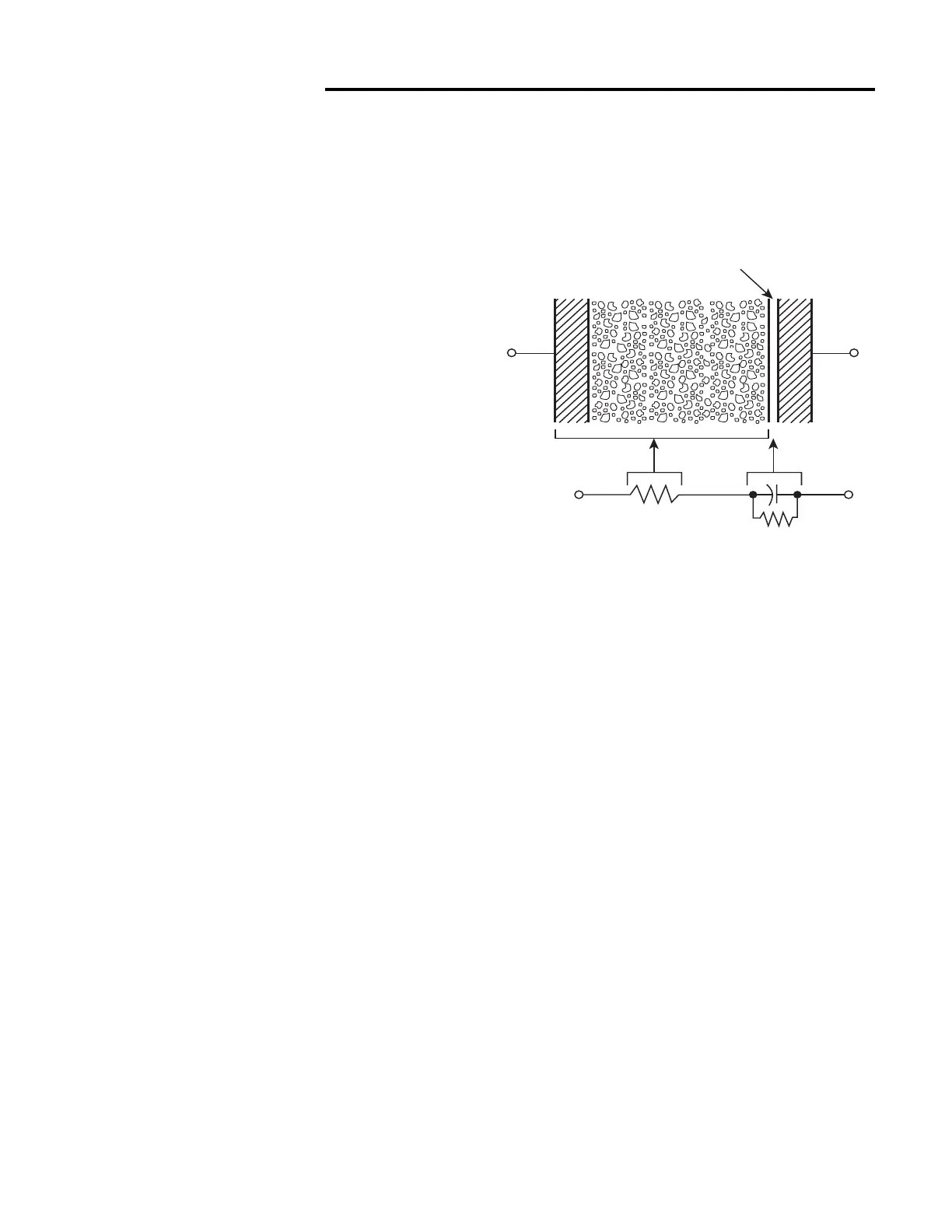

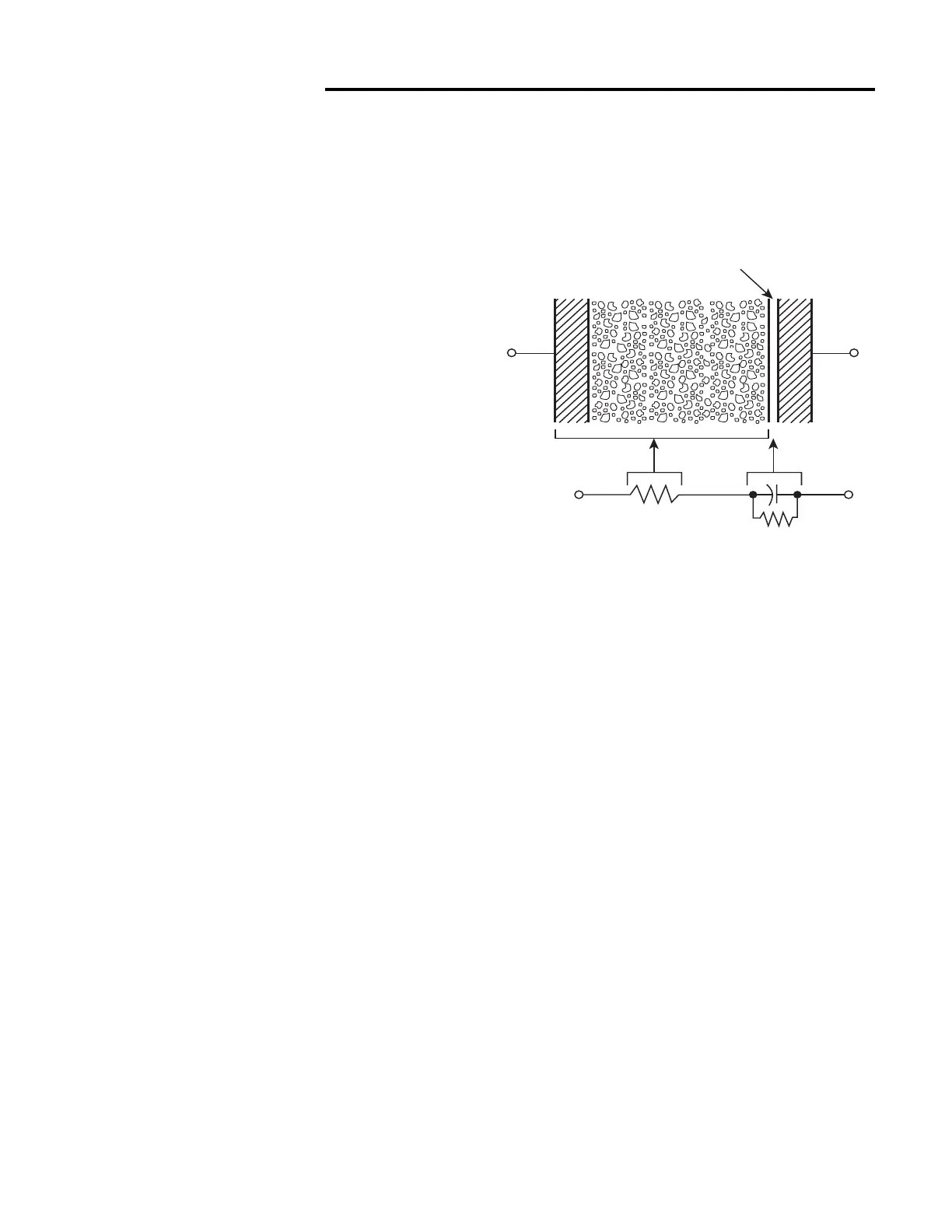

Fig. 38: Construction of an electrolytic capacitor and

its equivalent circuit.

Ceramics

Ceramic dielectric is the most versatile of all. Many

variations of capacity can be created by altering the

ceramic material. Capacitors that increase, stay the same

value, or decrease value with temperature changes can

be made. If a ceramic disc is marked with a letter P such

as P100, then the value of the capacitor will increase 100

parts per million per degree Celsius increase in

temperature. If the capacitor is marked NPO or COG,

then the value of capacity will remain constant with an

increase in the temperature.

Ceramic disc capacitors marked with an N such as

N1500 will decrease in capacity as the temperature

increases. The negative temperature coefficient is

important in many circuits such as the tuned circuits of

the radio and television IF. The temperature coefficient

of an inductor is positive and the inductance will

increase as the temperature rises. If the tuning capacitor

across the coil is a negative coefficient, then the net

result will be a zero or very little change.

General type ceramic discs are often marked with such

letters as Z5U, Z5F, Y5V, X5V, and so forth. This

indicates the type of temperature curve for the particular

capacitor. Ceramic capacitors that are not NPO or rated

with N or P type characteristics will have wider

temperature variations and can vary both positive and

Dielectric

Oxide Layer

Anode

Electrode

Cathode

Electrode

+

–

C

R

s

R

p

= Series Resistance

(Leads, Electrodes,

And Electrolyte)

= Leakage Resistance

Of Dielectric Film

Conducting

Electrolyte

Conducting

Electrolyte

Loading...

Loading...