UX-B20U/UX-B20C/B25C

3 – 1

FAXUX-B20U/UX-B20C/B25CService ManualService ManualMarketE

CHAPTER 3. MECHANISM BLOCKS

[1] General description

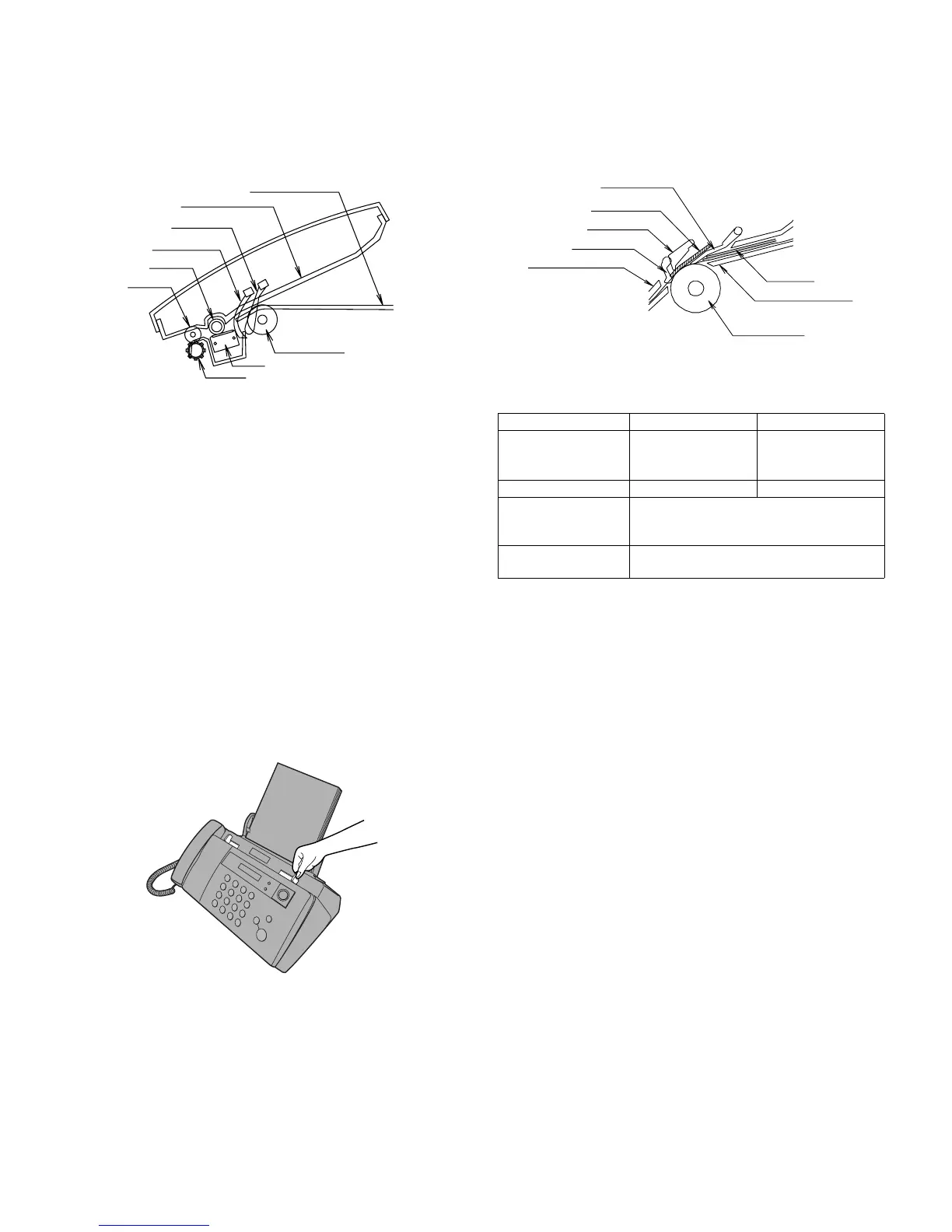

1. Document feed block and diagram

2. Document feed operation

1) The original, which is set in the document hopper, feeds automati-

cally when the FRSNS sensor is activated. This in turn activates

the drive motor which drives the paper feed roller. The document

stops when the lead edge is detected by the ORGSNS sensor.

2) The lead edge of the original is fed a specified number of pulses

after the lead edge of the document is detected for the reading pro-

cess to begin.

3) The trailing edge of the original is fed a specific number of pulses

after the trailing edge of the document deactivates the ORGSNS

sensor. The read process then stops and the original is discharged.

4) When the FRSNS sensor is in the OFF state (any document is not

set up in the hopper guide), the drive will be stopped when the doc-

ument is discharged.

3. Hopper mechanism

3.1. General view

The hopper section contains document guides that are used to adjust

the hopper to the width of the original document. This ensures that the

original feeds straight into the fax machine for scanning.

Document width: 148 mm to 216 mm (A5 longitudinal size to Letter

longitudinal size)

NOTE: Adjust the document guide after setting up the document.

3.2. Automatic document feed

1) Use of the paper feed roller and separate plate ensures error-free

transport and separation of documents. The paper feed plate

spring presses the document to the paper feed roller to assure

smooth feeding of the document.

2) Document separation method: Separate plate

3.3. Documents applicable for automatic feed

NOTE: Double-side coated documents and documents on facsimile

recording paper should be inserted manually. The document

feed quantity may be changed according to the document

thickness.

Documents corresponding to a paper weight heavier than 70 kg (80 g/

m

2

) and lighter than 135 kg (157 g/m

2

) are acceptable for manual

feed.

Documents heavier than 135 kg (157 g/m

2

) in terms of the paper

weight must be duplicated on a copier to make it operative in the fac-

simile.

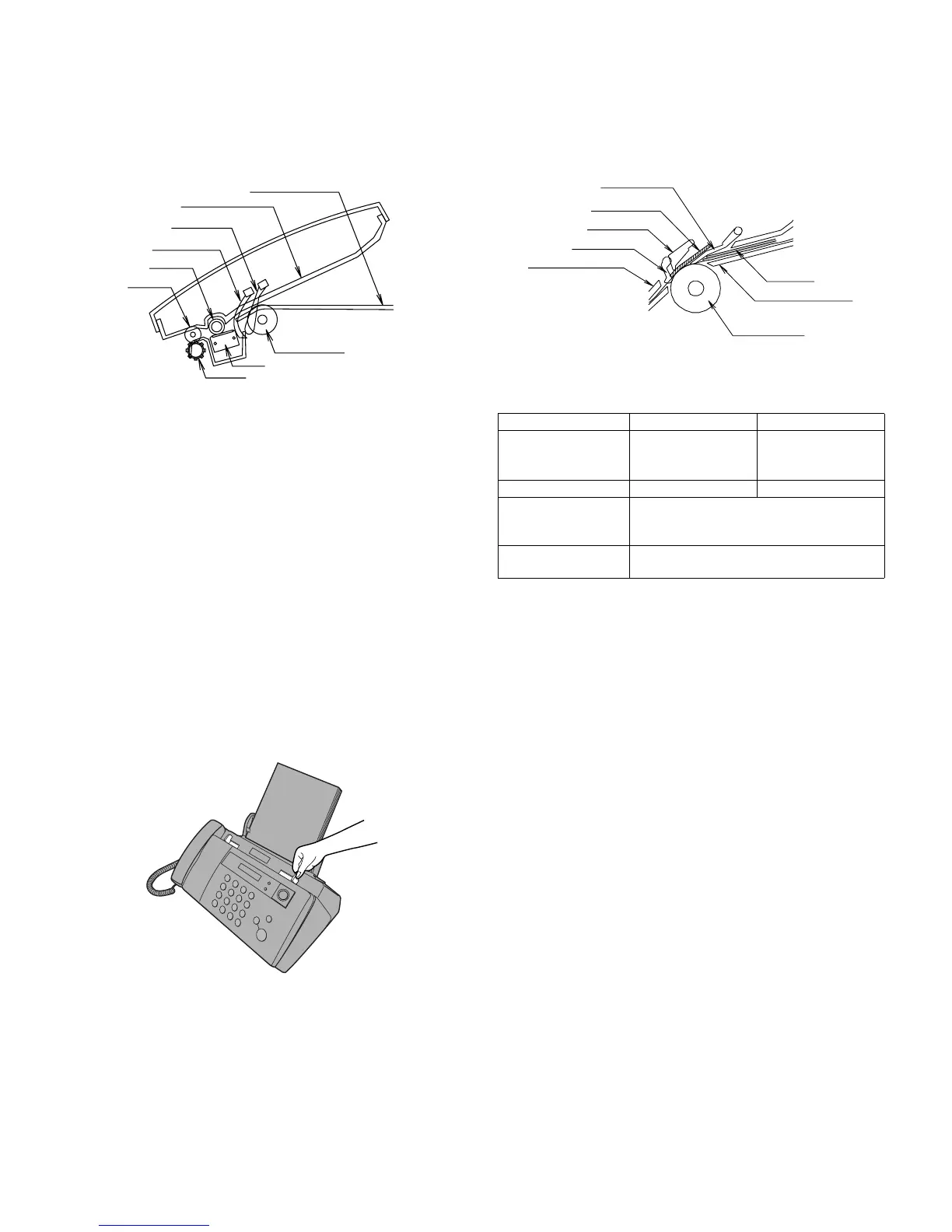

3.4. Loading the documents

1. Make sure that the documents are of suitable size and thickness,

and free from creases, folds, curls, wet glue, wet ink, clips, staples

and pins.

2. Place documents face down in the hopper.

i) Adjust the document guides to the document size.

ii) Align the top edge of documents and gently place them into the

hopper. The first page under the stack will be taken up by the

feed roller to get ready for transmission.

NOTE: 1) Curled edge of documents, if any, must be straightened

out.

2) Do not load the documents of different sizes and/or thick-

nesses together.

Fig. 1

Fig. 2

Paper feed roller

CIS

Exit roller

PO pinch roller

Back roller

ORGSNS sensor

FRSNS sensor

Document guide upper

Document guide lower

Fig. 3

10 sheets 1sheet(Manual)

Paper weight 70 kg

21.5 lbs.

(80 g/m

2

)

70 kg ~ 135 kg

14 lbs. ~ 42 lbs.

(52 g/m

2

~ 157g/m

2

)

Paper thickness (ref.) 0.1 mm 0.1 mm ~ 0.18mm

Paper size LGL (216 mm x 355.6 mm)

A4 (210 mm x 297 mm)

LTR (216 mm x 279 mm)

Feeder capacity A4/LTR: 10 sheets max.

LGL : 5 sheets max.

Document guide lower

Paper feed roller

Paper feed plate

Separate rubber

Separate plate

Sub feed plate

Document guide upper

Document

Loading...

Loading...