5.1 Installation

21

Magnetically Levitated Turbo Molecular Pump

INSTRUCTION MANUAL

5

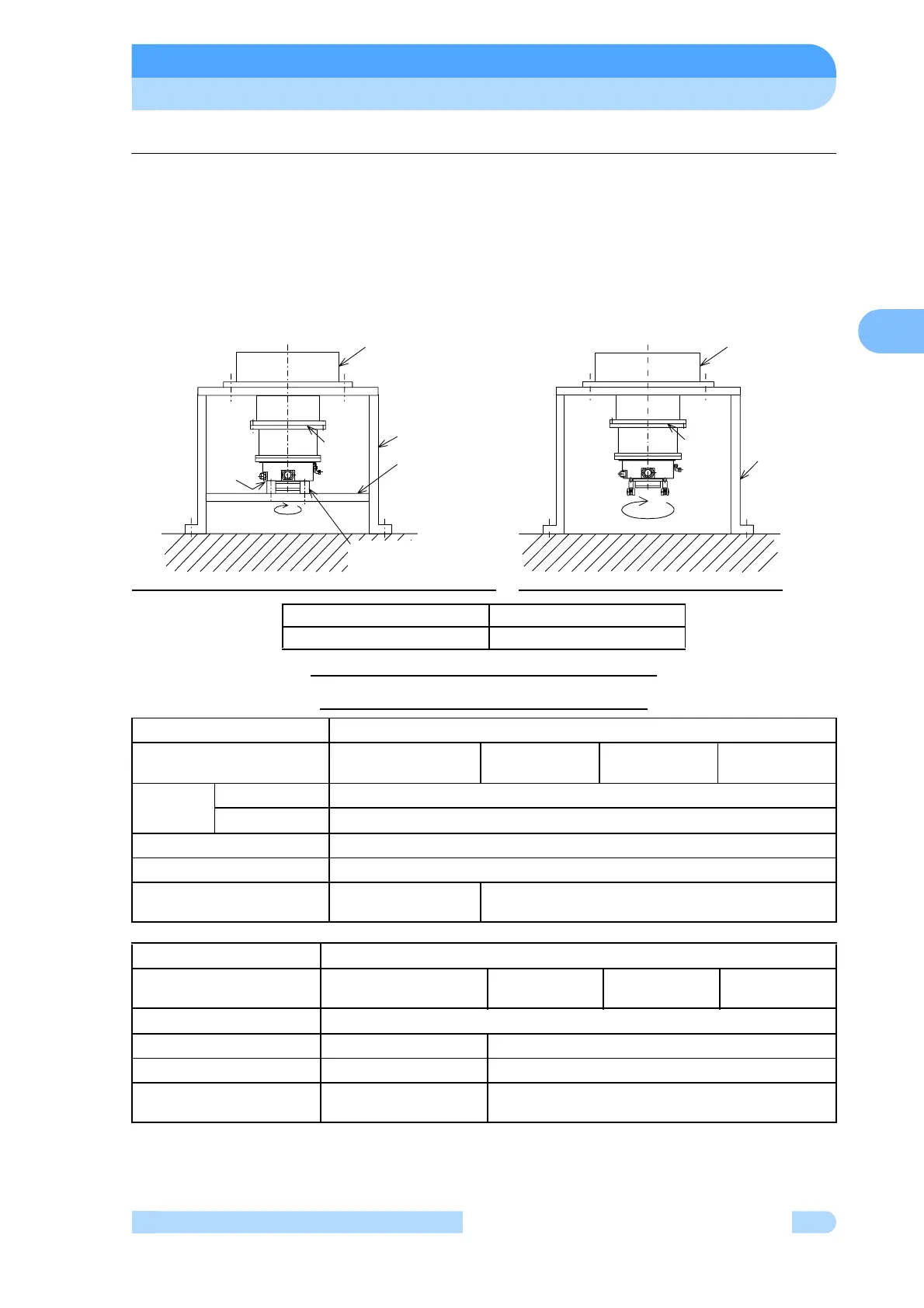

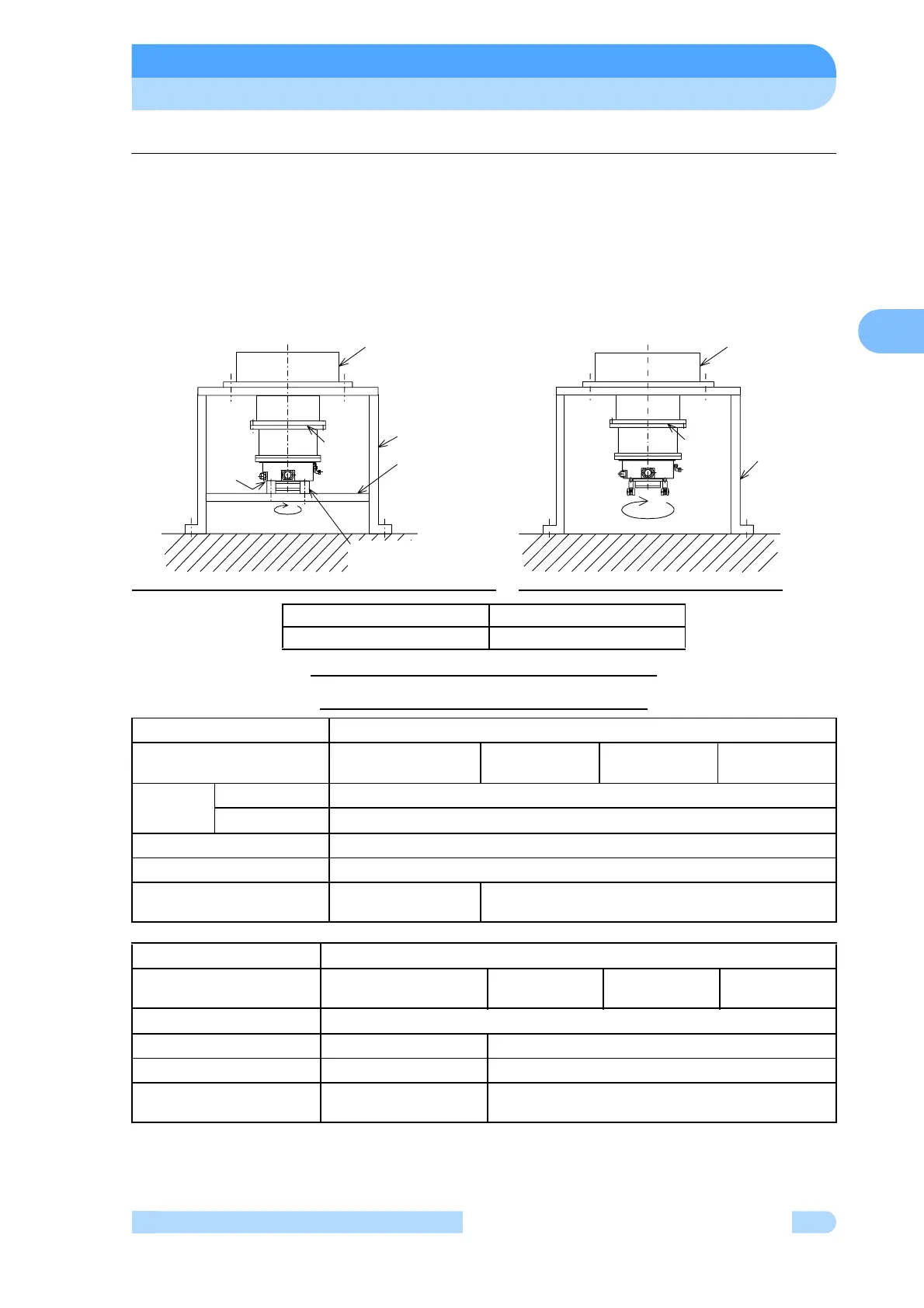

5.1.2.1 Installation of series of TMP-3203

Please fix the inlet flange of turbo molecular pump to the flange of vacuum chamber , and the

base bottom of the pump to the frame of the device by the bolts of regulated grade, size, number,

and tightening torque for each flange. (Refer to Table 5-1 and Table 5-2)

When you fix the pump, use all of the bolt holes of the inlet flange of the pump.

When you connect piping and the valve, etc. between the vacuum chamber and the turbo

molecular pump

,please fix all the bolt holes to those connection points by the method of fixing

the recommendation shown in Table 5-1and Table 5-2.

Fixed both by the inlet flange and the base of TMP

Fixed only by the inlet flange of TMP

Fig. 5-3 Installation of series of TMP-3203

Table 5-1 The recommended fixing bolt

(Note ) The special washers are attached to the inlet flange of TMP when shipping.

Do not remove them at the time of TMP installation.

Refer to Fig. 5-4 for the details of the bolt attaching part.

Description Rapid Shutdown Torque

TMP-3203M/MC/LM/LMC

59,100 N

・

m

Fixing method Both by the inlet flange and the base (recommended method)

Inlet flange VG350 VG300

ISO320B

Special

VG250

Bolt Size,

Quantity

Inlet flange

M12,12PC

Base

M16,8 PC

Material stainless steel

Grade

A2-70(JIS B 1054)

Washer

Plain washer and

spring lock washer

Special washer (Note) and spring lock washer

Fixing method Only by the inlet flange

Inlet flange VG350 VG300

ISO320B

Special

VG250

Bolt Size,Quantity

M12,12PC

Material stainless steel SCM435 (JIS G 4105) or equivalent

Grade

A2-70(JIS B 1054)

12.9 (JIS B 1051)

Washer

Plain washer and

spring lock washer

Special washer (Note) and spring lock washer

VACUUM

CHAMBER

OUTSIDE

DEVICE

INLET

FLANGE

Rods whitch have the

sufficient torque

strength.

DEVICE

FRAME

BASE

BOTTOM

RAPID SHUTDOWN

TORQUE

VACUUM

CHAMBER

OUTSIDE

DEVICE

INLET

FLANGE

RAPID SHUTDOWN TORQUE

Loading...

Loading...