SBG 00185 Copyright 2015 19

Quick-Start Guide for PRSalpha and PRSstandard tools

Onion skin

An opon for tabs is to leave an “onion skin,” or very thin layer of material at the boom of a prole

cut. Set the nal cut depth at slightly less than the thickness of your material (typically .010’’ - .030’’,

depending on material and size). The advantage of this method is that the onion skin can be easier to

trim away than a series of tabs. However, if there is a lot of variance in the thickness of your material,

or if your table is not at, then you may end up cung too deep or too shallow and this method will

not work correctly.

Warming Up the Spindle

Note: This step is not necessary for ShopBot machines with routers.

To maximize the life of spindle bearings, warm up the spindle before cung, aer leng it sit idle for

longer than 4 hours.

Click on “Tools” then “Spindle RPM control” to open the spindle control window. Leaving this window

open, start the spindle warm up roune (C5 command). This will run the spindle at 9000, 10000, and

12000 RPM for 3 minutes each, and will turn o the spindle when nished.

Previewing a le with an oset

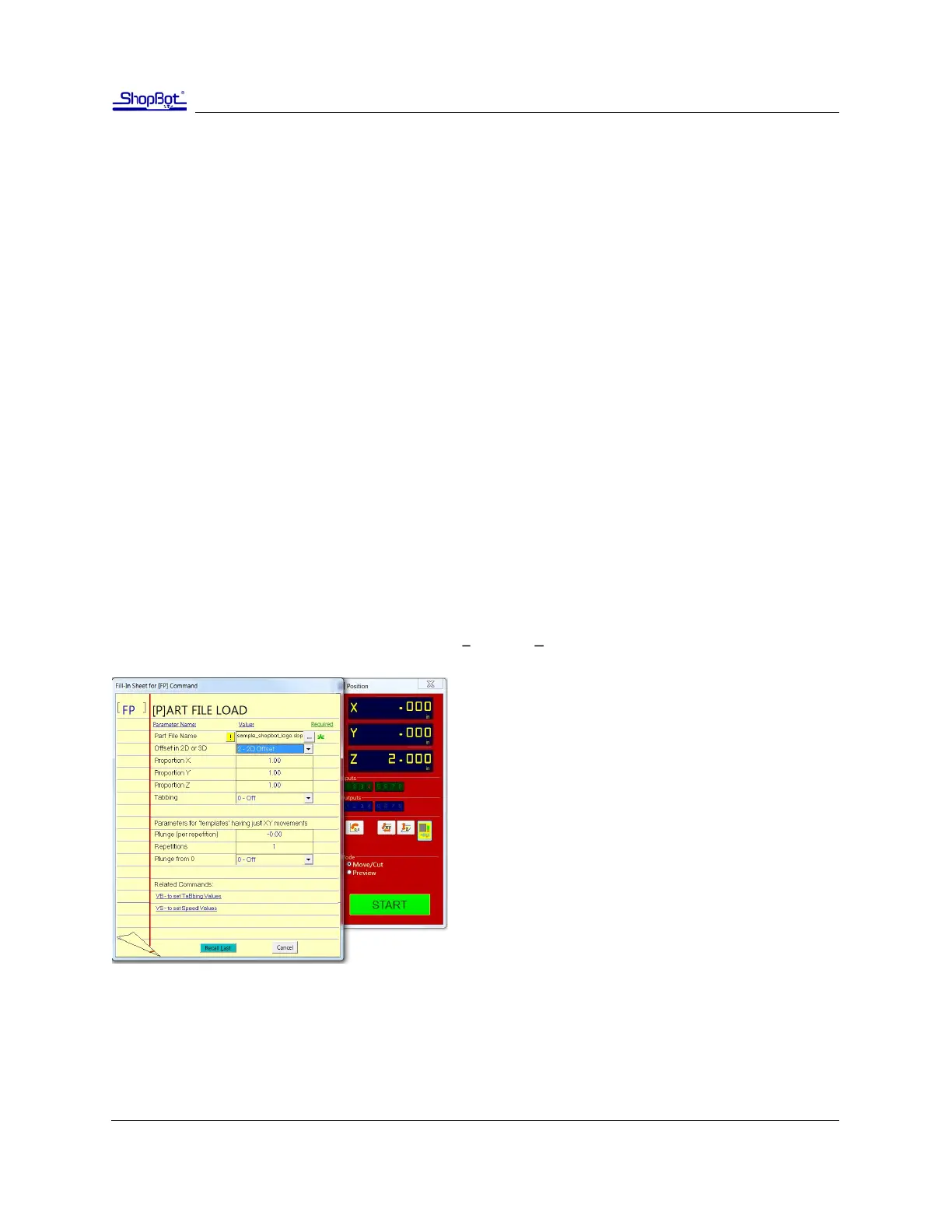

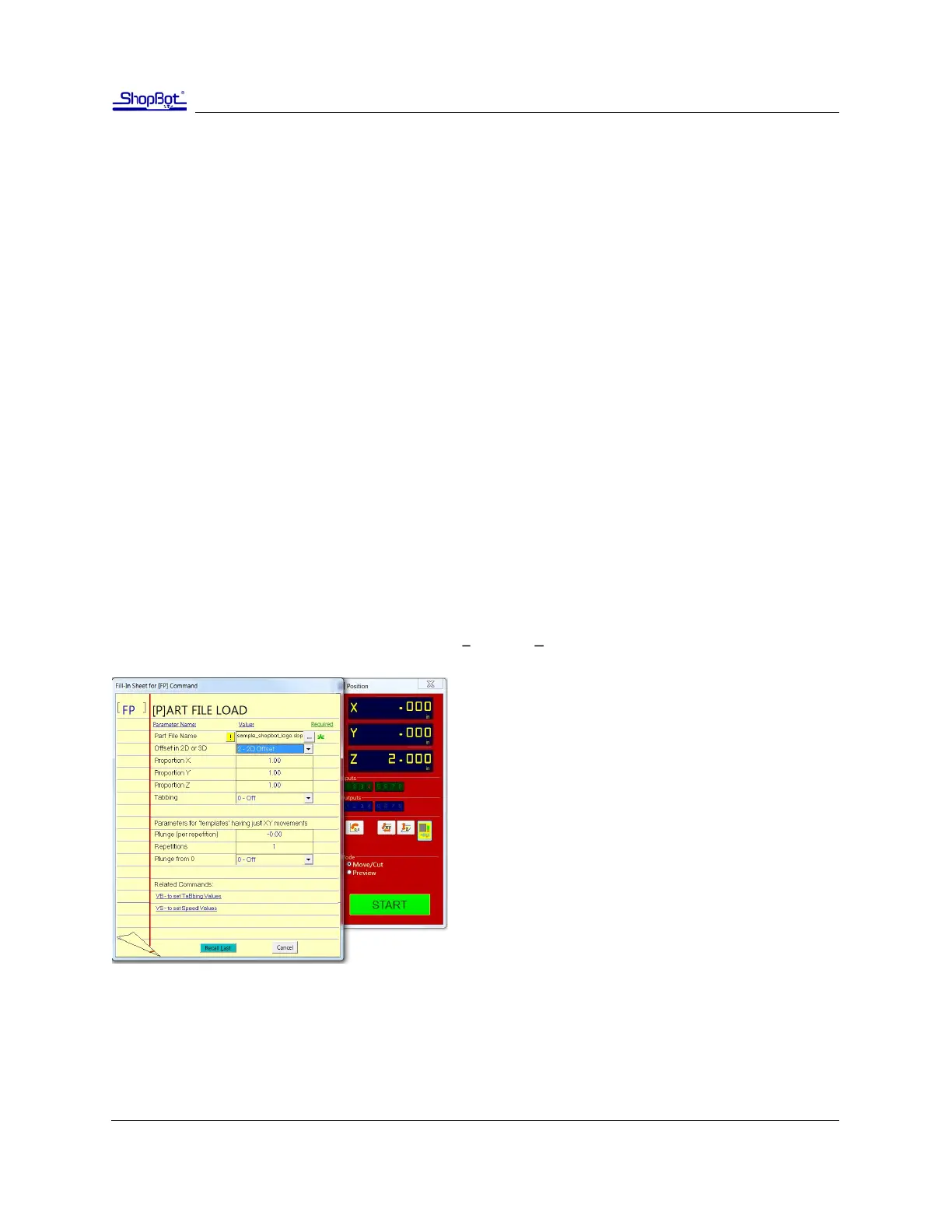

There are several ways to perform a “test run” without actually cung the material. First, enter Move/

Cut mode, and click on the “Cut Part” buon (or “File” and “Part File Load”). Select part le, and the

following screen will appear.

Locate the line marked “Oset in 2D or 3D.”

A 2D oset will cut the le at normal depth in a dier-

ent X,Y locaon on the table. Once the X, Y, and Z axes

are zeroed, simply move the cuer to the new locaon

and load the part le with a 2D oset. Its current loca-

on will be used as 0,0.

A 3D oset will cut at a dierent X, Y, and Z posi-

on. This is oen referred to as “air cung,” since

it allows you to run through the le in the air

above the material. To avoid cung into the

workpiece, make sure that the starng distance

between the bit and the material is greater than the maximum cut depth.

Click “START” or Enter on your keyboard to proceed.

Loading...

Loading...