SBG 00185 Copyright 2015 22

Quick-Start Guide for PRSalpha and PRSstandard tools

Secon 3. Technical Basics

This secon provides an overview of some basics to safely and eciently plan your projects. This is not

a comprehensive guide. More informaon can be found in the user’s manual, or online from the re-

sources listed in the back of this Guide.

Please be sure to review the general safety page in front of this manual before running the machine.

Bits

Bit material: Router bits are made from a variety of materials. The most common bits are solid car-

bide, carbide-pped steel, and high-speed steel. ShopBot recommends either solid carbide or carbide-

pped bits. High-speed steel bits dull quickly and must be re-sharpened oen.

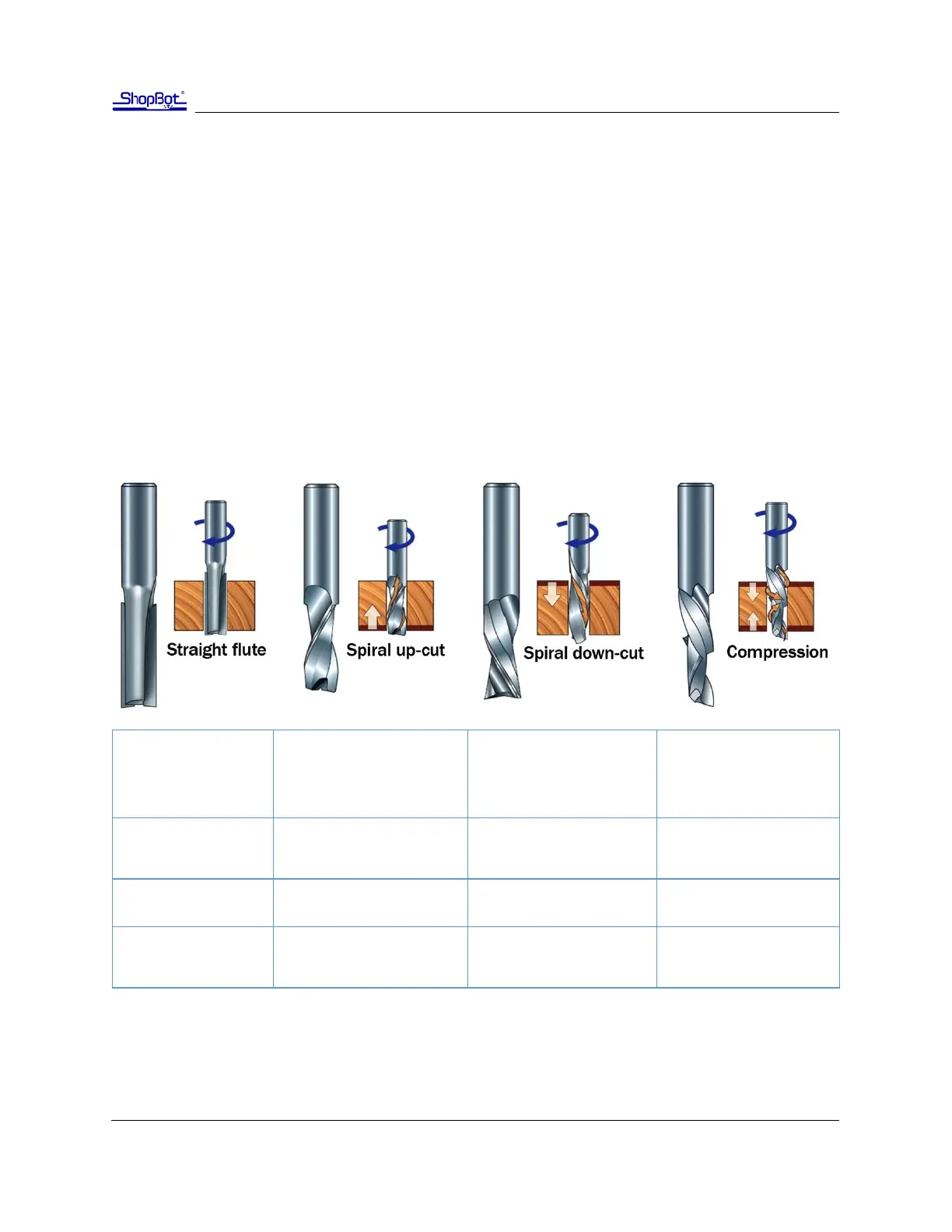

Flute type: There are four basic ute types: Straight, spiral up-cut, spiral down-cut, and compression.

Each type has its own advantages and disadvantages, which are outlined below.

Good edge quality on

most materials

May chip or fray top face,

good quality on boom face

when through-cung

Best edge quality on top face,

may chip or fray boom face

when through-cung

Clean edge on both top and

boom face

Moderate chip clearing

abilies

Excels at clearing chips and

dissipang heat, especially with

“o-ute” bits

May compact chips in a groove Designed to cut veneered or

laminated materials at full

depth in one pass

Upward force may cause part

liing

Downward force may help with

cung thin sheets

Ideal for: general-purpose

cung

Ideal for: plascs, aluminum, or

any material where heat

buildup is a concern

Ideal for: plywood and lami-

nates (pockeng)

Ideal for: plywood and lami-

nates (prole cung)

Loading...

Loading...