5.4 Connection

DANGER

D

e-energize the system!

The plant could inadvertently start while you are connecting the devices.

b

Make sure that the entire plant is disconnected from the voltage supply during all

electrical installation work.

Only use a suitable voltage supply!

The sensor must be connected to a voltage supply of protection class 2 SELV/PELV

24 V DC, +10 %/–15 %.

Prevent the formation of a potential difference between the load and the protective

device!

b

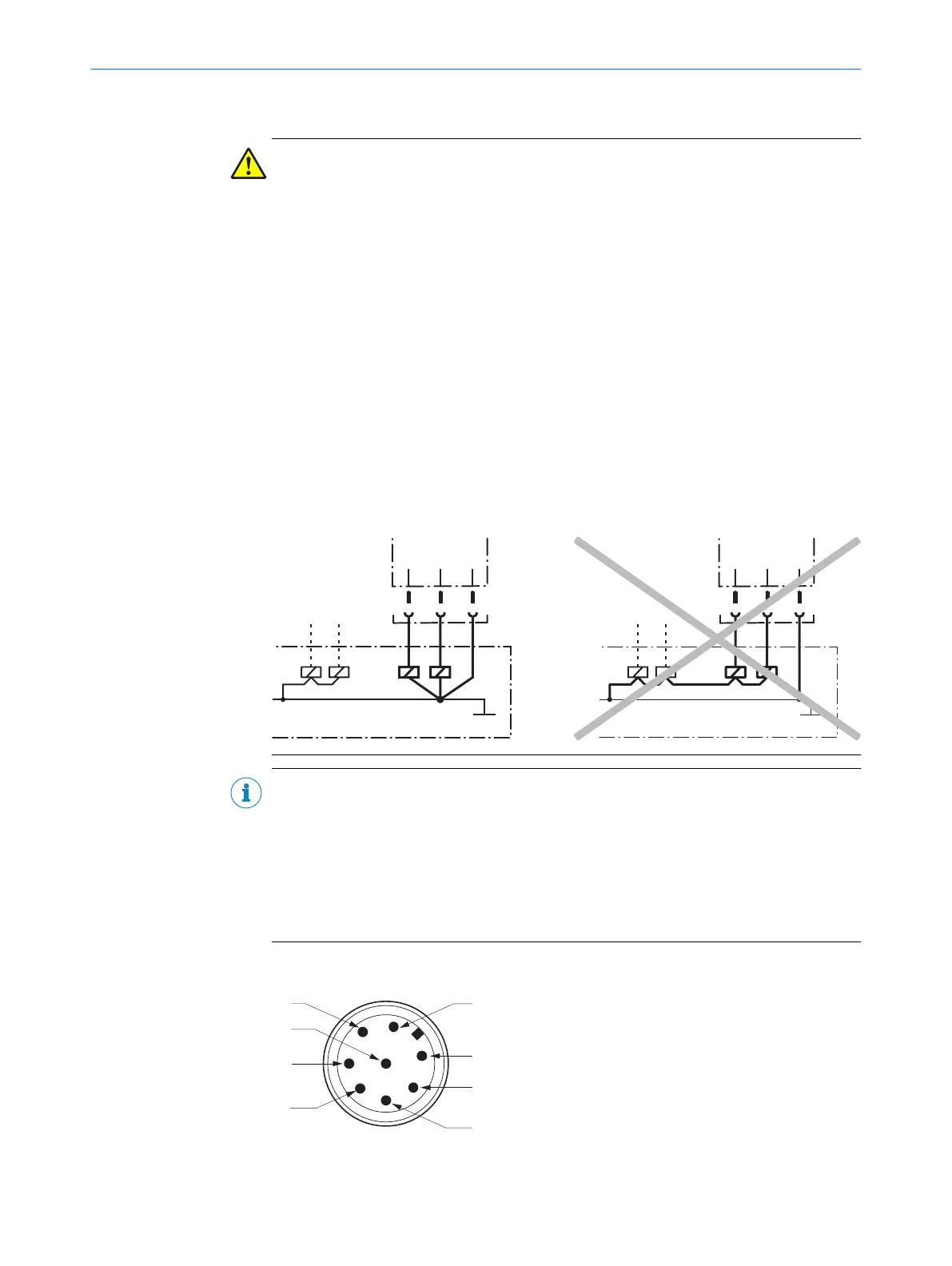

If you connect the loads to the OSSDs or safety outputs that do not have reverse

polarity protection, you must connect the 0 V connections of these loads and

those of the corresponding protective device separately and directly to the same

0 V terminal strip. In the event of a fault, this is the only way to ensure that there

can be no potential difference between the 0 V connections of the loads and

those of the corresponding protective device.

NOTE

•

T

he safety switch complies with the regulations for electromagnetic compatibility

(EMC) for the industrial sector (Radio Safety Class A). Radio interference cannot

be ruled out when used in residential areas.

•

In order to minimize network influences on the device behavior, the external volt‐

age supply of the devices (SELV/PELV) must be able to bypass events, including a

power outage of 20 ms. Power supply units according to EN 60204-1 fulfill this

prerequisite. Suitable power supply units are available as accessories from SICK.

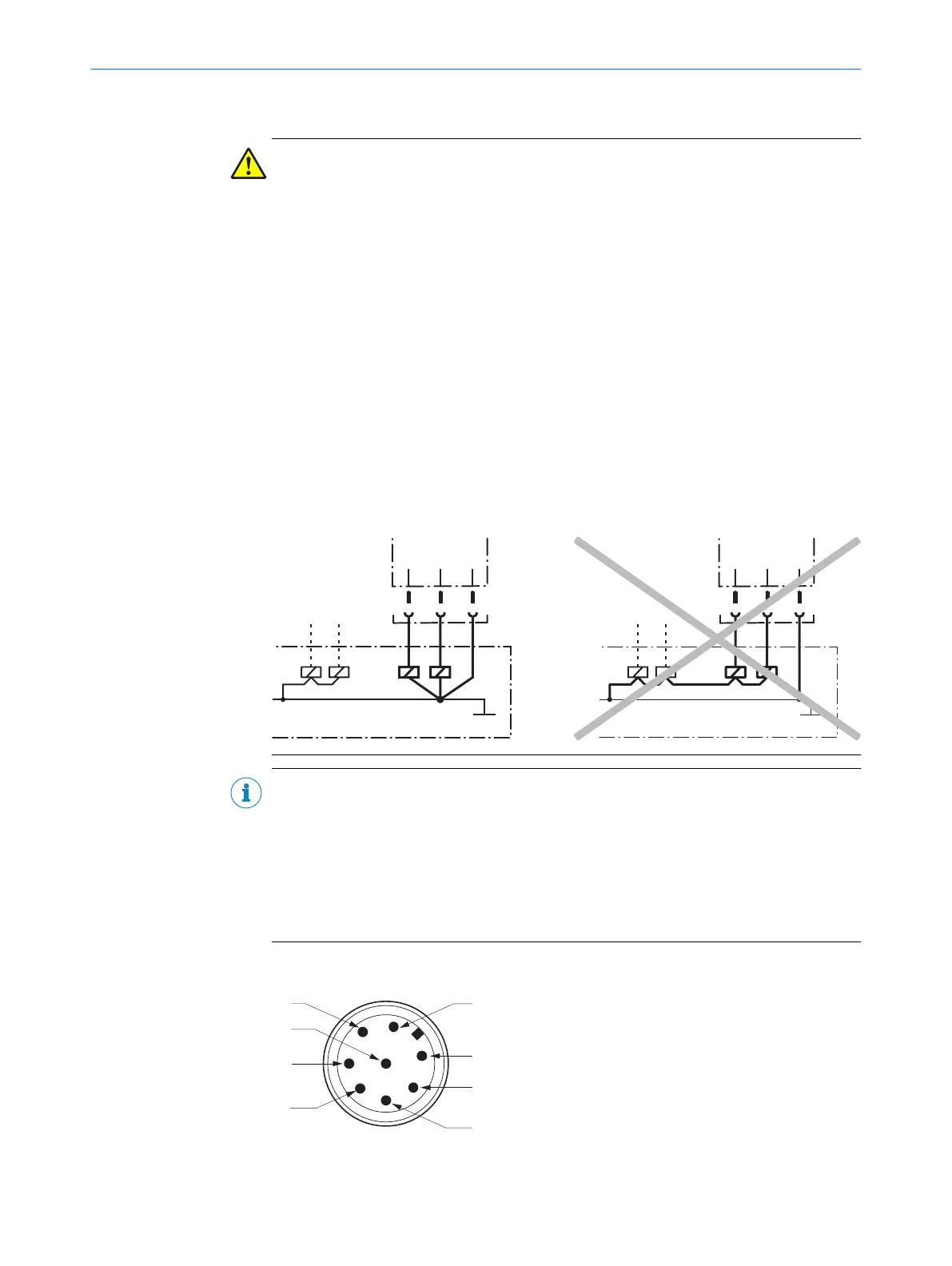

5.4.1 Device connection (M12, 8-pin or cable variant)

Figure 3: Device connection (M12, 8-pin)

5 ELE

CTRICAL INSTALLATION

14

O P E R A T I N G I N S T R U C T I O N S | TR4 Direct Cylindrical 8022968/15V1/2019-11-22 | SICK

Subject to change without notice

Loading...

Loading...