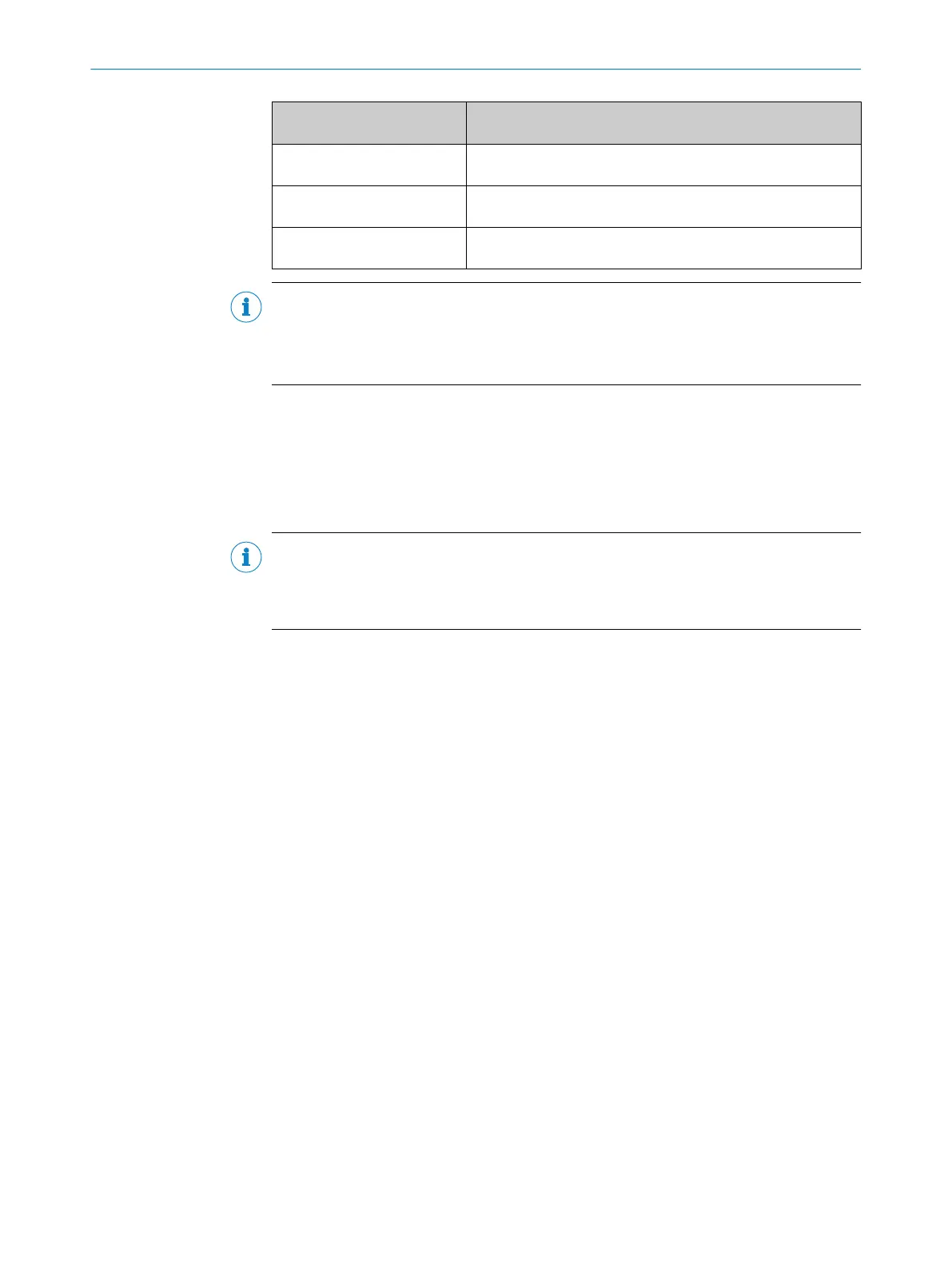

Display of the Status/Diag

LED (4 Hz)

Meaning

Ö 3 × r

ed, 3 × green

The actuator was moved out of sensing range (RFID signal inter‐

r

upted).

Ö 3 × r

ed, 4 × green

Eight actuators have been taught in. No other teach-in process

is pos

sible.

Ö 3 × r

ed, 5 × green

The device has been interlocked. No other teach-in process is

pos

sible.

NOTE

T

he fault indicators are repeated until the device is reset.

b

To reset the device, interrupt the voltage supply to the device for at least 3 sec‐

onds.

6.3 Inspection instructions

6.3.1 Checks before initial commissioning

Check the protective device as described below and in accordance with the applicable

s

tandards and regulations.

NOTE

The tests before initial commissioning described in the following are used to detect the

influence on the protection system by unusual ambient influences.

These checks must therefore always be performed.

b

Chec

k the effectiveness of the protective device of the machine in all operating

modes in which the machine can be set.

b

Ensure that all operators have been instructed by the qualified safety personnel

before they start working on a machine protected by a safety switch. Instruction is

the responsibility of the machine user.

The tests must be documented accordingly.

6.3.2 Regular inspection of the protective device by qualified safety personnel

b

Chec

k the plant following the inspection intervals specified in the national rules

and regulations. If any changes are made to the machine or someone tampers

with the protective device after initial commissioning, this will ensure that any

such issues are detected.

b

If substantial alterations have been made to the machine or protective device, or if

safety switches have been changed or repaired, check the plant again.

6.3.3 Regular testing of the effectiveness of the protective device

Check if the safety switch is functioning correctly at regular intervals and after each

er

ror. You can find possible time intervals in ISO 14119.

How to check the effectiveness of the mounted safety switch

b

Check whether the machine always switches off when a protective door is opened.

b

Check that the switch cables are operating properly.

b

Check the protective device for signs of misuse or manipulation.

b

Check the switch housing for damage.

COMMISSIONING 6

8022968/15V1/2019-11-22 | SICK O P E R A T I N G I N S T R U C T I O N S | TR4 Direct Cylindrical

19

Subject to change without notice

Loading...

Loading...