Connector Pin Assignment

12.10 X9 – Motor Feedback

Sine cosine encoder, incremental encoder TTL (5.3 V), incremental encoder 12 V, Hall

encoder (5.3 or 12 V), linear Hall encoder, field plate sensor, Heidenhain EnDat encoder,

Stegmann SSI encoder, Hiperface encoder

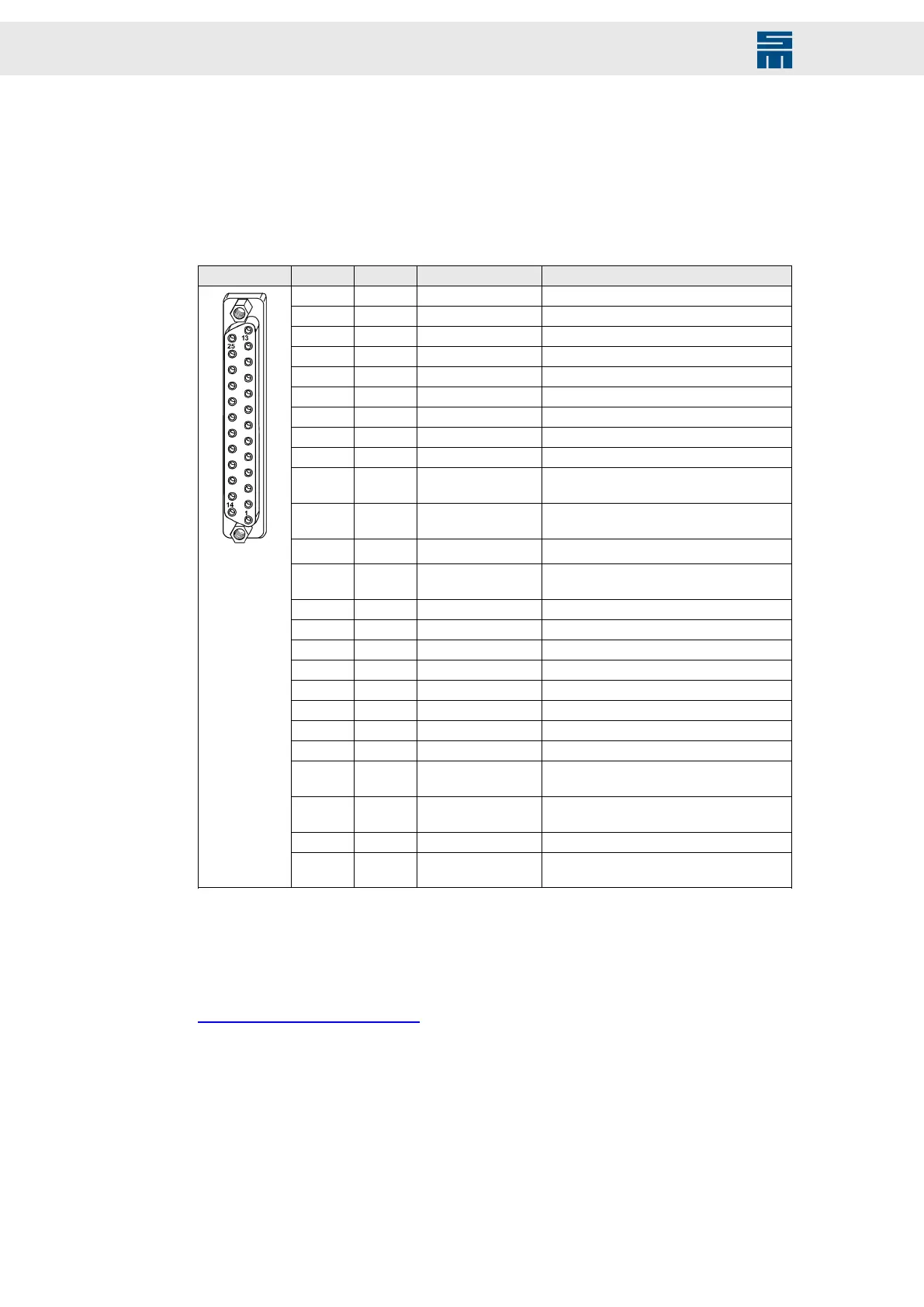

25-pole female submin D connector

X9 Pin I/O Name Meaning

1 I/O GND Ground

2 I O Hall sensor 12 V track A

3 I B Hall sensor 12 V track B

4 I C Hall sensor 12 V track C

5 O VCC_12 Measuring system supply 12 V

6 I COS- Cosine-

7 I/O GND Ground

8 I SIN- Sine-

9 O VCC_5 Measuring system supply 5.3 V

10 I/O DATA+ / UA + EnDat data+ / track A+ / RS485+ / Hall sen-

sor 5 V differential

11 I Zero+ / UN+ Zero pulse+ / track N+ / Hall sensor 5 V dif-

ferential

12 I

TEMP

(1)

Temperature sensor of the motor

13 O CLK+ / UB+ EnDat Clock+ / track B+ / Hall sensor 5 V

differential

14 I/O GND Ground

15 I/O GND Ground

16 I/O GND Ground

17 I/O GND Ground

18 I FP Field plate

19 I COS+ Cosine+

20 I/O GND Ground

21 I SIN+ Sine+

22 I Zero- / UN- Zero pulse- / track N- / Hall sensor 5 V dif-

ferential

23 I/O Data- / UA- EnDat data- / track A- / RS485- / Hall sen-

sor 5 V differential

24 O 24 V Output

25 O CLK- / UB- EnDat Clock- / track B- / Hall sensor 5 V

differential

(1)

The temperature sensor is connected between GND and TEMP.

Locking bolts flange: max. tightening torque = 0.7 Nm

Related topics

X9 – Motor Feedback, page 138

114 Drive System SD2 - Hardware Description

Loading...

Loading...