Description

3.3 Design

Synchronous/induction motors 1PH813

Operating Instructions, 04/2009, 610.48000.22

23

Water cooling

The motor can only be operated in a closed cooling-water circuit with a heat-exchanger unit.

The motor is connected to the cooling circuit by means of two female threads on the rear of

the motor. The operator can decide on the best method of connecting the inlet and outlet.

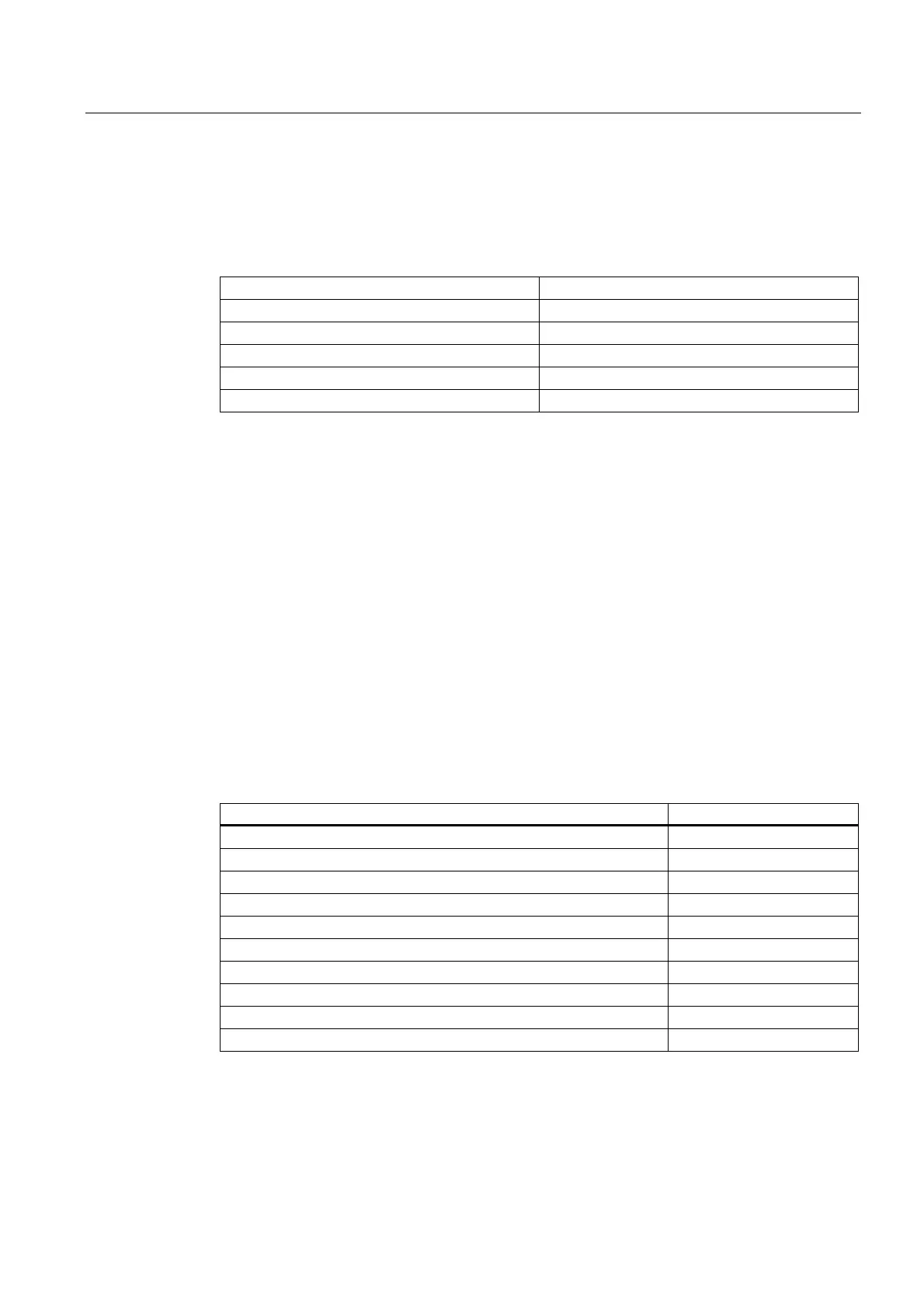

Cooling water connection G3/8"

Cooling water flow 12 l/min

Max. pressure at inlet 6 bar

Pressure loss between inlet and outlet 0.9 bar

Min. cooling water inlet temperature T

cooling

> T

ambient

- 5 K

Max. cooling water inlet temperature +30 °C

Only water enriched with appropriate quantities of additives to protect against corrosion and

minimize the growth of algae can be used as a coolant.

If there is a risk of frost, preventive measures must be taken during operation, storage, and

transportation (anti-freeze, emptying and blowing out with air, etc.).

A filter (100 µm) must be installed in the inlet pipe to protect the motor against

contamination. Additional protection for the motor must be provided by means of a pressure

relief valve installed downstream of the filter.

The values specified for the cooling water also apply to the requirements of closed cooling

circuits. Not all of the specified concentrations will occur in the cooling water at the same

time.

Cables and fittings can be made out of brass, stainless steel, or plastic. If different materials

are used in close proximity to each other, however, the electrochemical series must be taken

into account, which is why zinc must not be used in cooling water circuits.

If a throttle is needed to restrict the flow, it is best to install it downstream of the motor. It

must not be installed directly in front of the inlet because the effects of cavitation may

damage the motor.

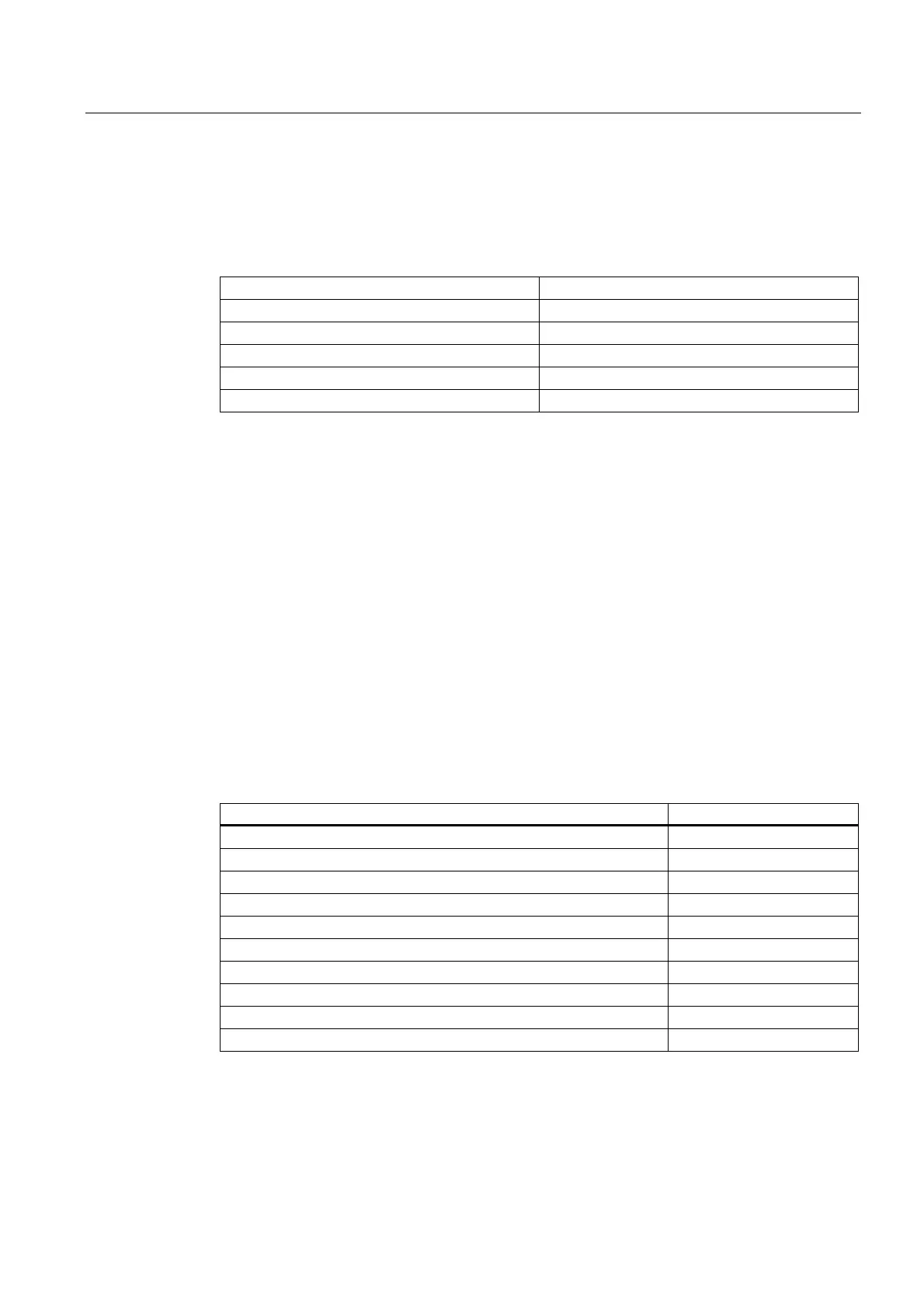

Table 3- 5 Chemical requirements of the cooling water

Content and chemical composition Value

pH value 6 - 9

Chloride ions < 40 ppm

Sulfate ions < 50 ppm

Nitrate ions < 50 ppm

Dissolved solids < 340 ppm

Total hardness < 170 ppm

Electrical conductivity < 500 μS/cm

Size of any particles in the coolant < 100 µm

Tyfocor anti-freeze 20 - 30 %

NALCO 00GE056 inhibitor 0,2 - 0,25 %

Loading...

Loading...