Installation

5.3 Attaching the output elements

Synchronous/induction motors 1PH813

Operating Instructions, 04/2009, 610.48000.22

33

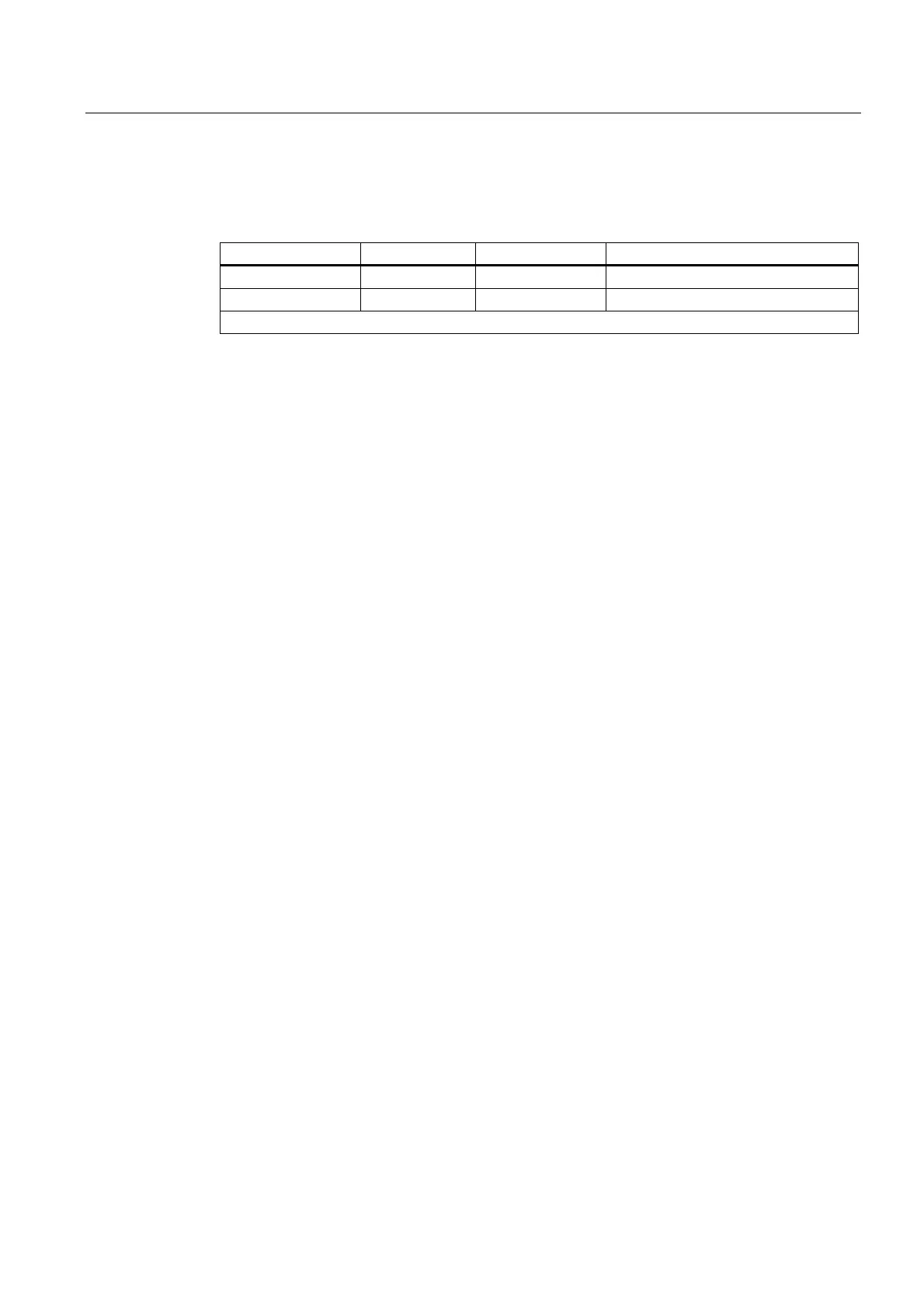

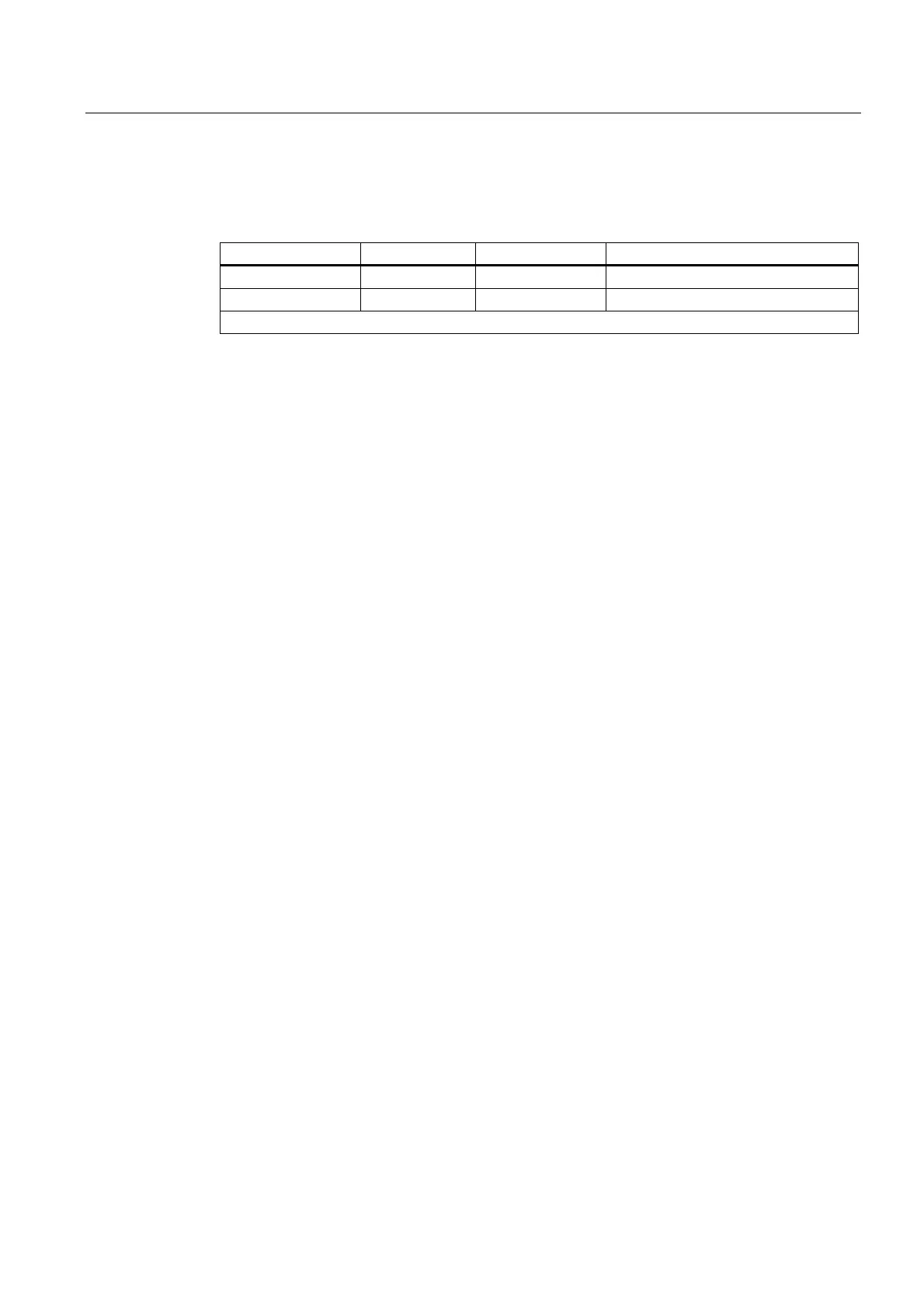

Tightening torques

Table 5- 1 Tightening torques for foot/flange mounting

Mounting type Screw ISO 4017 Washer ISO 7092 Tightening torque ± 10% [Nm]

Mounting foot M10 10 (d2 = 18) 42

Flange mounting M16 12 (d2 = 28) 165

Use screws of property class 8.8 or higher.

Alignment accuracy for coupling output

The maximum concentricity of the shafts of the motor and the driven machine is 0.05 mm in

diameter.

5.3 Attaching the output elements

Balancing

The rotors are balanced dynamically. The motors are equipped with a smooth shaft as

standard. For shaft ends with feather keys, the balancing method at the DE of the shaft is

indicated as follows:

● "H" means Halfkey = balancing with a half feather key

● "F" means Fullkey = balancing with a whole feather key

Pushing on the output elements

● Make sure that the balancing method of the output element is correct! The output

elements must be balanced to balance quality grade G2.5 to ISO 1940. Rotary forces that

exceed this are not permissible.

● If the output element is shorter than the feather key with balancing method "H", the

section of the feather key that protrudes from the shaft contour and output element must

be removed to maintain the balance quality.

● Output elements must only be fitted/removed using suitable equipment.

– Use a threaded hole in the shaft end (front).

– If necessary, heat up the output element.

– When removing output elements, use an intermediate washer to maintain the

centering in the shaft end.

Loading...

Loading...