Maintenance

9.2 Repair

Synchronous/induction motors 1PH813

70 Operating Instructions, 04/2009, 610.48000.22

9.2.2 Removing/installing the motor

Removal

● When removing the motor, mark the original position of the components with respect to

each other (e.g. using a colored pen, scribing iron) to make subsequent installation

easier.

● For information on how to remove the encoder, see "Removing the speed encoder".

● Unscrew the NDE bearing shield screws and carefully remove the NDE bearing shield.

● Unscrew the bearing cap screws (see "Spare parts", item 1.02).

● Remove the grease slingers from the shaft shoulder (DE).

● Remove the rotors from the motor. Use a suitable device to remove the rolling-contact

bearings.

Installation

● Do not reuse rolling-contact bearings that have been removed.

● Heat up the new rolling-contact bearings evenly to 80 - 100°C and attach them. When

doing so, make sure that the bearing inner ring lies on the shaft shoulder.

● The device must not be subject to hard knocks (e.g. do not use a hammer etc.).

● Insert the motor rotor into the stator.

● Secure the bearing cap.

● Insert the NDE bearing (with shaft spring) into the NDE flange (keep the bearing straight)

and tighten the screws.

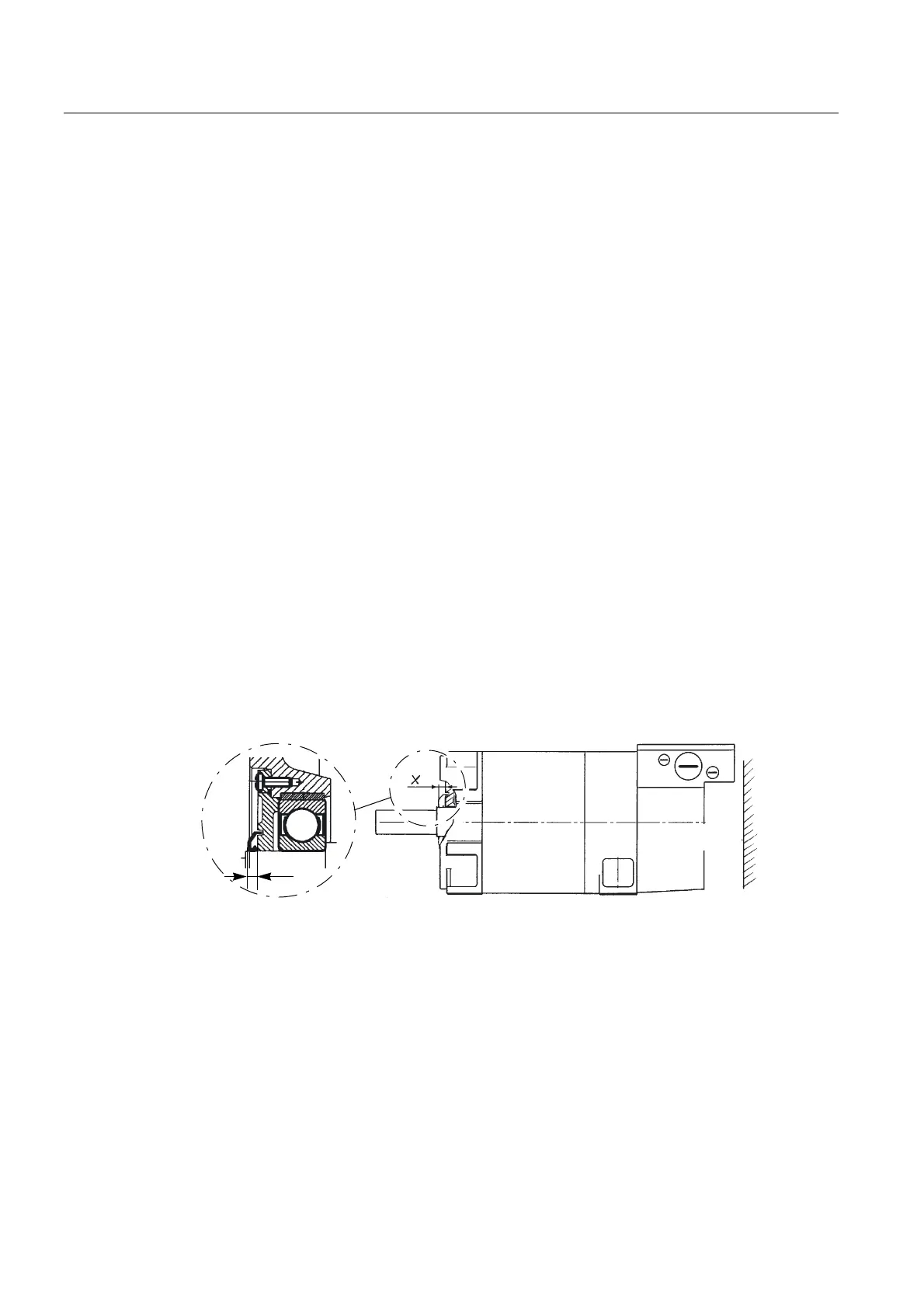

x

Figure 9-1 Installing the gamma ring

● Press on the grease slinger (gamma ring housing 9RB... without sealing lip) with a

suitable sleeve (dimension x = 0 mm (flush with cover)). Do not use any grease slingers

that were damaged when removed.

Running in the bearings

Once you have replaced the bearings, allow the rolling-contact bearings to run in to distribute

the grease evenly. When doing so, the motors should be initially run continuously from 0 to

approx. 75% of the maximum speed n

max

over a period of 15 minutes.

Loading...

Loading...