Decommissioning and disposal

11.1 Decommissioning

Synchronous/induction motors 1PH813

82 Operating Instructions, 04/2009, 610.48000.22

Copper recovery

Some components (e.g. stator) contain a considerable amount of copper. This copper can

be recovered from the electrical insulation in a heat treatment process, which involves

gasifying the organic binding materials. To ensure that the vapors burn properly, the oven

must be equipped with a suitable afterburner. The following conditions are recommended for

heat-treating and afterburning to minimize process emissions:

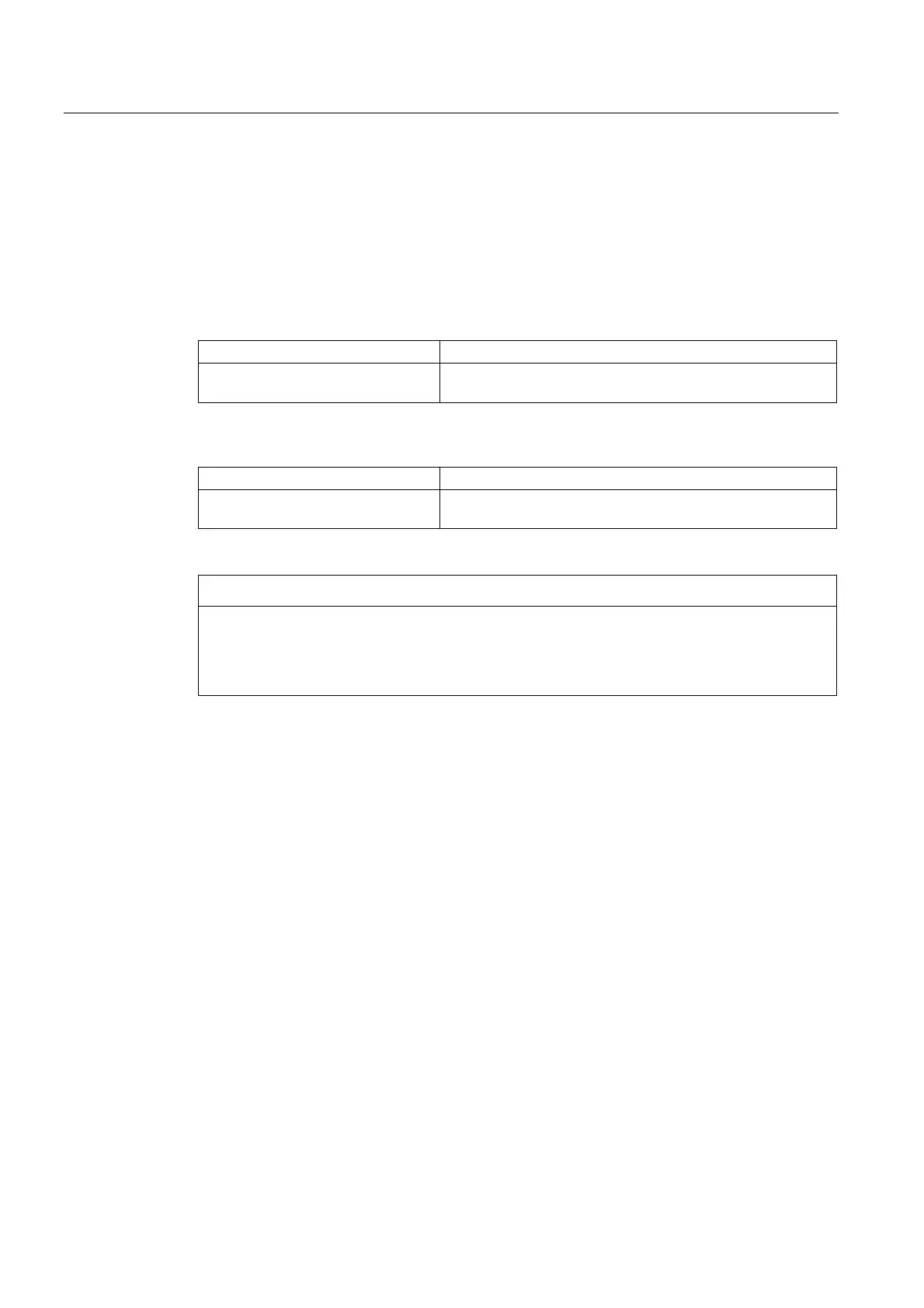

Table 11- 1 Heat treating

Temperature 380 … 420 °C (716 … 788 °F)

Duration Once 90% of the target temperature has been reached, the

object must be kept at that temperature for at least five hours.

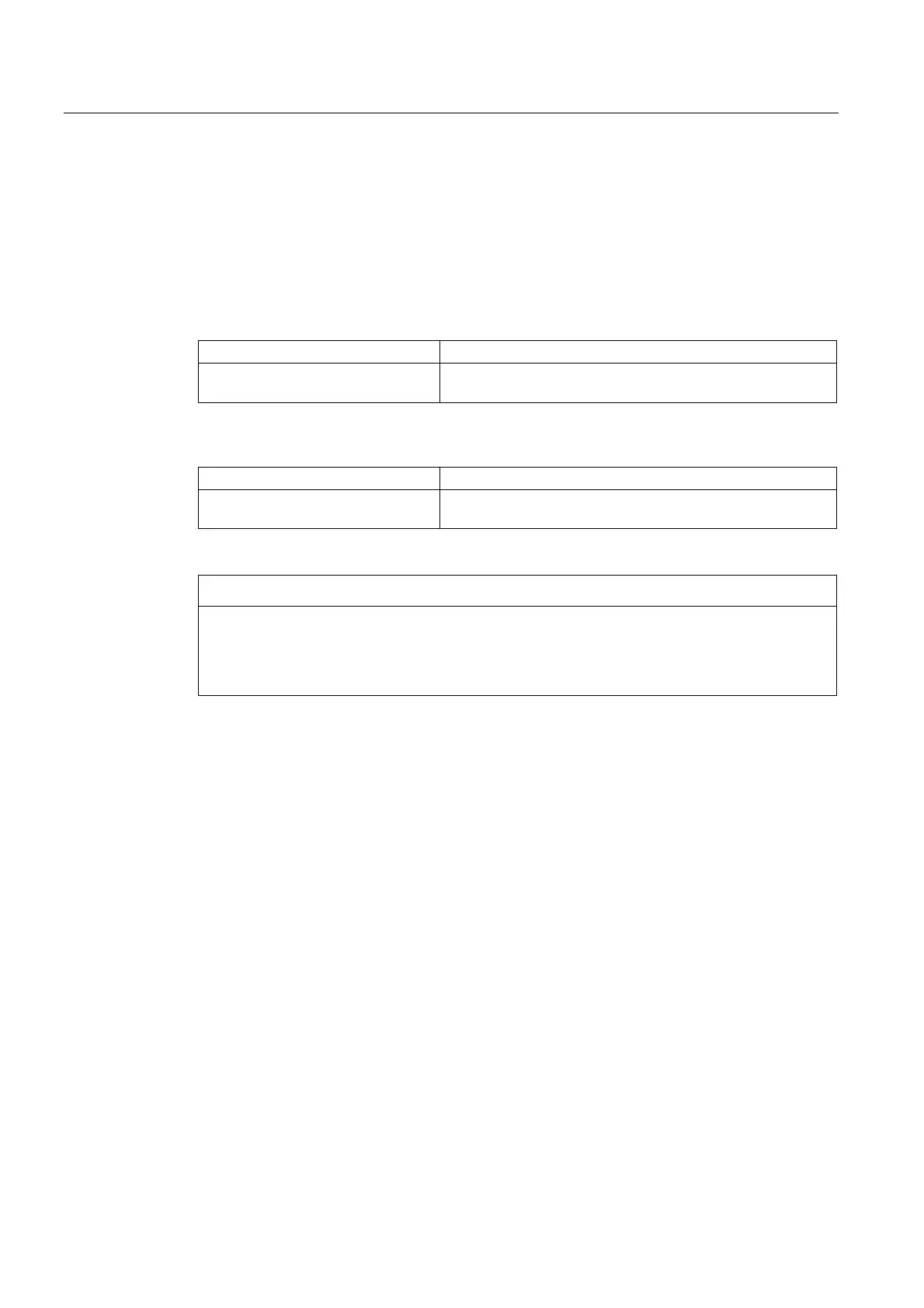

Table 11- 2 Afterburning of the binding material vapors

Temperature 850 … 920 °C (1562 … 1688 °F)

Flow velocity The binding material vapors must remain in the combustion

chamber for at least 3 seconds.

NOTICE

Emissions

The emissions mainly constitute O

2

-, CO-, CO

2

-, NO

x

-, C

x

H

y

gases and microscopic

particles. As the operator, you are responsible for ensuring that the heat treatment process

complies with local regulations.

Anti-corrosion agent

Anti-corrosion agents that cover the surface of the motor can be removed by means of a

gasoline-based cleaning agent and a rag. Dispose of the rag in accordance with local

regulations.

Loading...

Loading...