Setting functions

8.3 Setpoints

Inverter with CU230P-2 Control Units

240 Operating Instructions, 11/2013, FW V4.6.6, A5E02430659B AG

Table 8- 8 Setting the fieldbus as setpoint source

p1070 = 2050[1]

Interconnect the main setpoint with process data PZD2 from the fieldbus.

p1075 = 2050[1]

Interconnect the additional setpoint with process data PZD2 from the fieldbus.

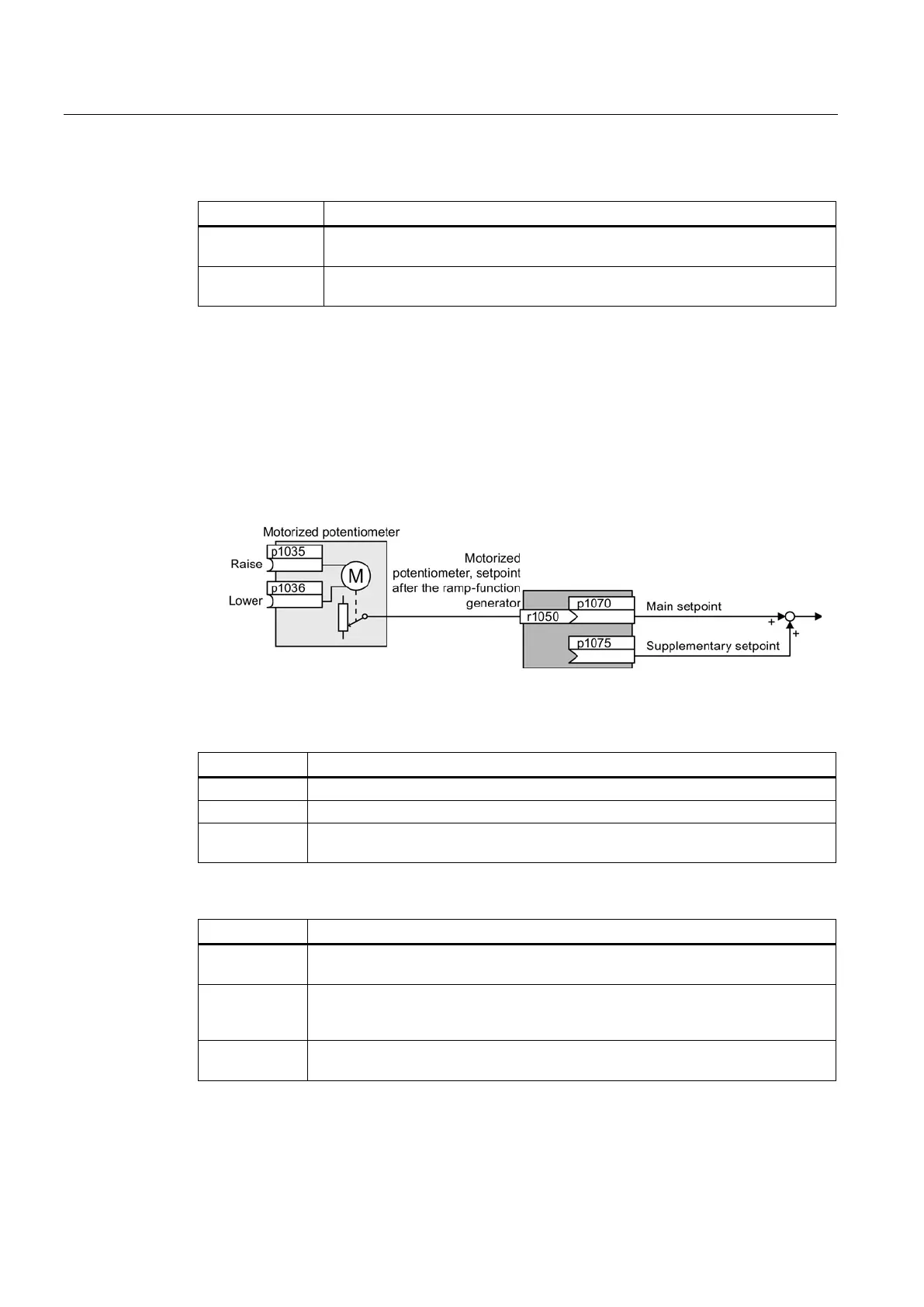

Motorized potentiometer as setpoint source

The "Motorized potentiometer" function emulates an electromechanical potentiometer. The

output value of the motorized potentiometer can be continually set using the "up" and "down"

control signals.

Interconnecting the motorized potentiometer (MOP) with the setpoint source

Figure 8-14 Motorized potentiometer as setpoint source

Table 8- 9 Basic setup of motorized potentiometer

MOP ramp-up time (factory setting: 10 s)

MOP ramp-down time (factory setting: 10 s)

p1040

(factory setting: 0 rpm)

Defines the start value [rpm], which is effective when first switching on the motor.

Table 8- 10 Setting the MOP as setpoint source

p1070 = 1050

Interconnecting the main setpoint with MOP.

p1035

Motorized potentiometer, increase setpoint

Interconnect this signal, for example with a digital input of your choice:

p1035 = 722.1 (digital input 1)

p1036

Motorized potentiometer, decrease setpoint

Interconnect this signal, for example with a digital input of your choice.

Loading...

Loading...