Setting functions

8.7 Application-specific functions

Inverter with CU230P-2 Control Units

Operating Instructions, 11/2013, FW V4.6.6, A5E02430659B AG

275

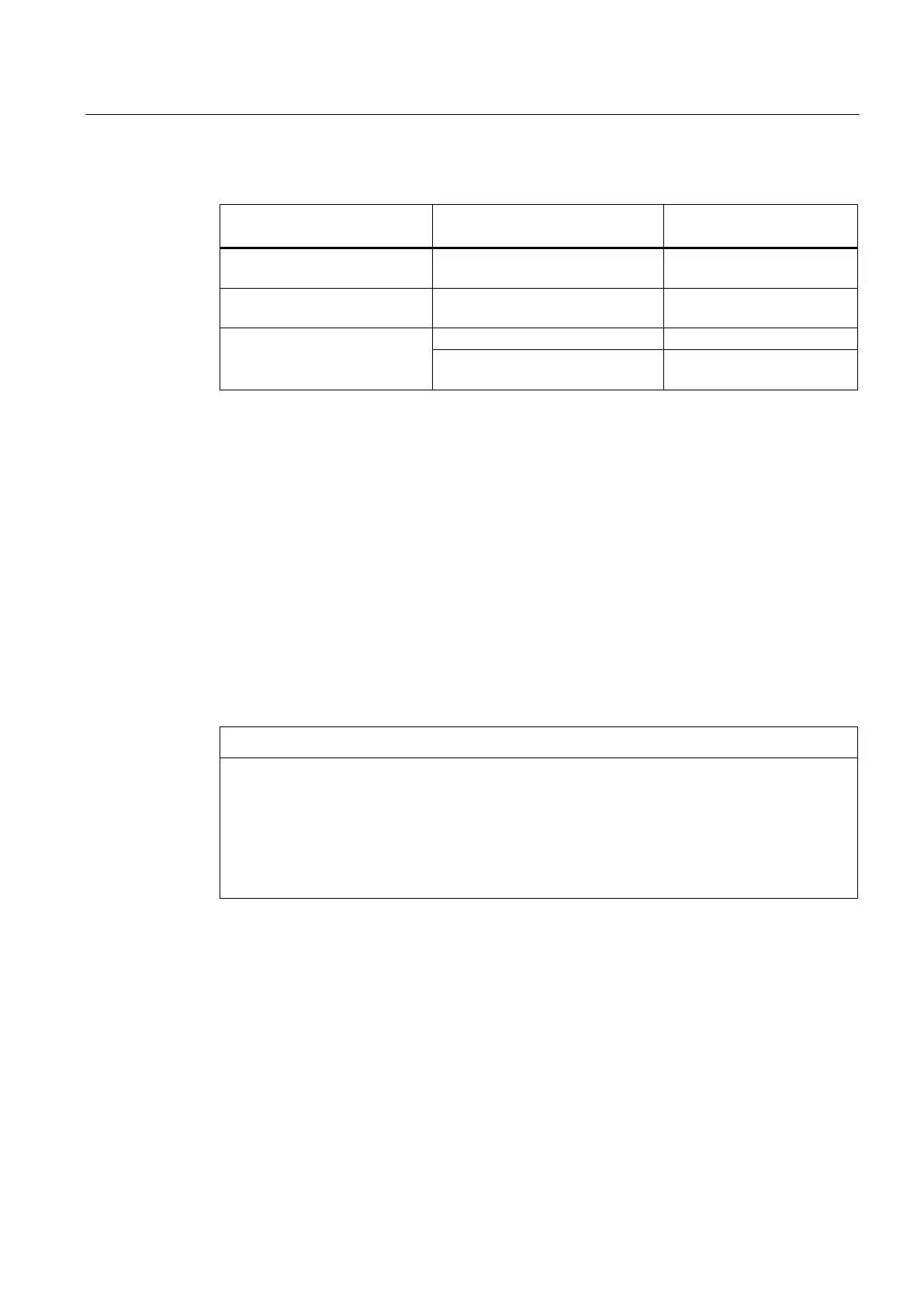

Braking method depending on the application

Electrical braking methods

Power Modules that can be

used

Pumps, fans, mixers,

Not required PM230, PM240, PM250,

Grinding machines, conveyor

DC braking, compound braking PM240

Centrifuges, vertical conveyors,

hoisting gear, cranes, winders

Braking with regenerative feedback

PM250, PM260

DC braking is used for applications without regenerative feedback into the line supply, where

the motor can be more quickly braked by impressing a DC current than along a braking

ramp.

Typical applications for DC braking include:

● Centrifuges

● Saws

● Grinding machines

● Conveyor belts

Motor damage caused by overheating

The motor can overheat if it is braked for long periods of time or frequently using DC

braking. This may damage the motor.

• Monitor the motor temperature.

• If the motor gets too hot during operation you must select another braking method or

give the motor more time to cool down.

With DC braking, the inverter outputs an internal OFF2 command for the time that it takes to

de-energize the motor p0347 - and then impresses the braking current for the duration of the

DC braking.

The DC-braking function is possible only for induction motors.

Loading...

Loading...